High-density small-particle-size nickel-cobalt-manganese hydroxide and preparing method thereof

A technology of hydroxide and nickel-cobalt-manganese, which is applied in the field of high-density and small-size nickel-cobalt-manganese hydroxide and its preparation, can solve the problem of low tap density on the particle surface, non-uniform distribution of nickel-cobalt-manganese, and uneven particle size and other problems, to achieve the effect of low production cost, good physical and chemical indicators of the product, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

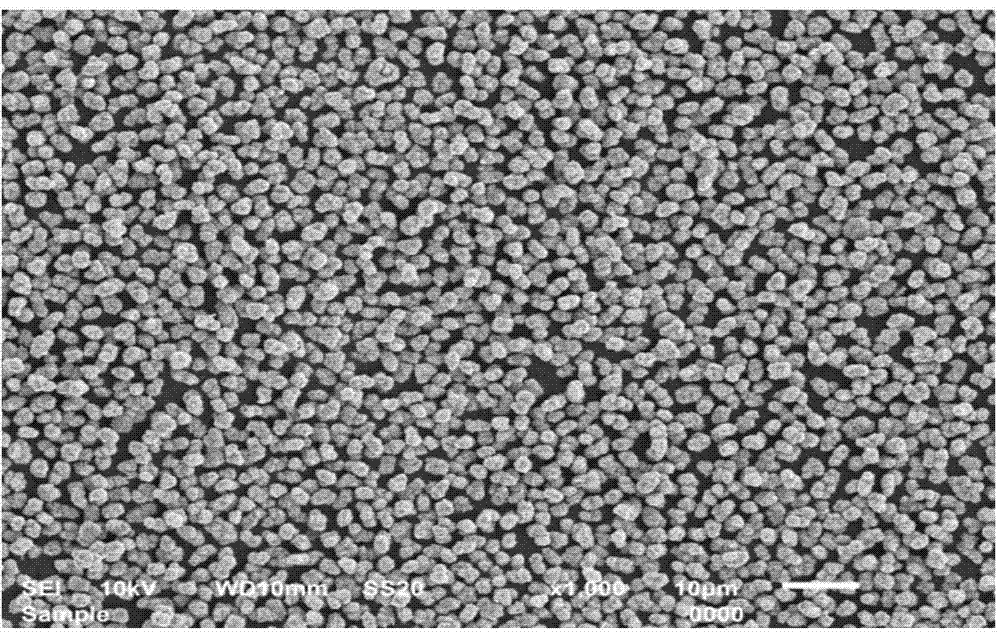

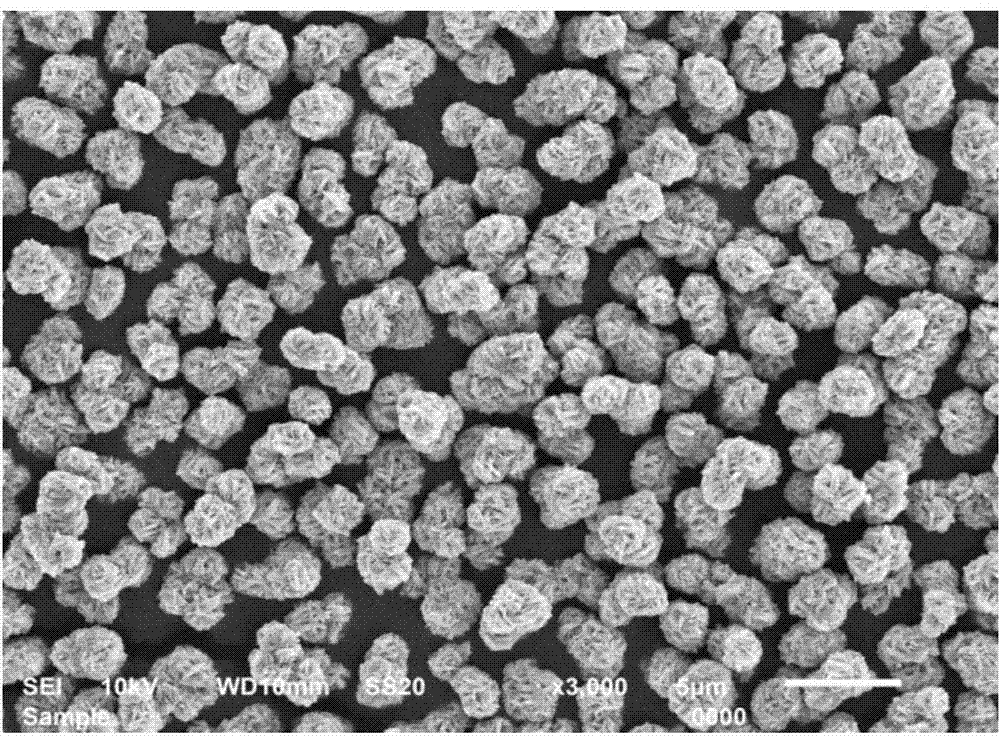

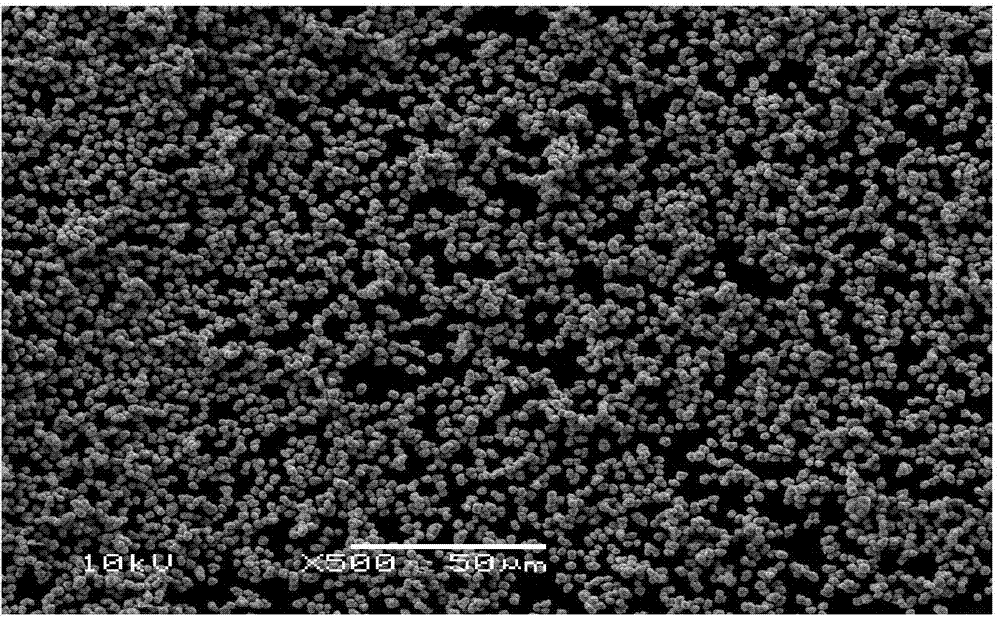

[0043] Ni 1 / 3 co 1 / 3 mn 1 / 3 (OH) 2 : d10=3.26um, d50=3.47um, d90=3.62um, tap density=1.42g / cm 3 , specific surface area=12.27m 2 / g, spherical or quasi-spherical.

[0044] (1) According to the molar ratio of Ni:Co:Mn 1:1:1, prepare a nickel-cobalt-manganese sulfate mixed aqueous solution with a concentration of 1.5mol / L, prepare a sodium hydroxide aqueous solution with a concentration of 8mol / L, and prepare a concentration of 10mol / L of ammonia solution;

[0045] (2) Add mother liquor with an ammonia concentration of 0.15mol / L and a pH of 11.6 into a 100L reactor equipped with a temperature-controlled water bath jacket, a stirring paddle, and a precision filter tube as the bottom water, which just submerges the entire reactor mixer;

[0046] (3) Inject nitrogen gas into the sealed reaction kettle all the time, the nitrogen gas flow rate is 1L / min, start stirring at 150 rpm, and adjust the pH of the bottom water to 12.5 with 8mol / L sodium hydroxide solution;

[0047] (...

Embodiment 2

[0056] Ni 0.5 co 0.2 mn 0.3 (OH) 2 : d10=3.18um, d50=3.39um, d90=3.52um, tap density=1.53g / cm 3 , surface area=13.7m 2 / g, spherical or quasi-spherical.

[0057] (1) According to the molar ratio of Ni:Co:Mn 5:2:3, prepare a nickel-cobalt-manganese sulfate mixed aqueous solution with a total concentration of 1mol / L, prepare a sodium hydroxide aqueous solution with a concentration of 8mol / L, and prepare a concentration of 8mol / L L of ammonia solution;

[0058] (2) Add mother liquor with an ammonia concentration of 0.19mol / L and pH=11.78 into a 5000L reactor equipped with a temperature-controlled water bath jacket, a stirring paddle and a precision filter tube as the bottom water, which just submerges the entire reactor mixer;

[0059] (3) Inject nitrogen gas into the sealed reaction kettle all the time, the nitrogen flow rate is 30L / min, start stirring at 150 rpm, adjust the pH of the bottom water to 12.6 with 8mol / L sodium hydroxide solution

[0060] (4) Start crystal n...

Embodiment 3

[0069] Ni 0.6 co 0.2 mn 0.2 (OH) 2 : d10=3.01um, d50=3.21um, d90=3.42um, tap density=1.63g / cm 3 , surface area=10.72m 2 / g, spherical or quasi-spherical.

[0070] (1) According to the molar ratio of Ni:Co:Mn 6:2:2, prepare a nickel-cobalt-manganese chloride mixed aqueous solution with a total concentration of 0.5mol / L, and prepare a sodium hydroxide aqueous solution with a concentration of 6mol / L. The prepared concentration is 8mol / L ammonia solution;

[0071] (2) Add the ammonia concentration of 0.16mol / L and pH=11.65 to the 100L reactor with a temperature-controlled water bath jacket, stirring paddle and precision filter tube as the bottom water. The bottom water is just right All stirring paddles without passing through the reactor;

[0072] (3) Inject nitrogen gas into the sealed reaction kettle all the time, the nitrogen gas flow rate is 1L / min, start stirring at 180 rpm, adjust the pH of the bottom water to 12.8 with 6mol / L sodium hydroxide solution

[0073] (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| D90 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com