Apparatus for automatically detecting fusion jointing state of crystal and fusion silicon liquid level in vertical pulling type single crystal furnace

An automatic detection device and single crystal furnace technology, applied in the direction of crystal growth, single crystal growth, self-melting liquid pulling method, etc., can solve the problems of full melting of seed crystal, increased labor intensity, hidden danger of accidents, melting of seed crystal chuck, etc. , to achieve the effect of preventing melting accidents, reducing labor intensity and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

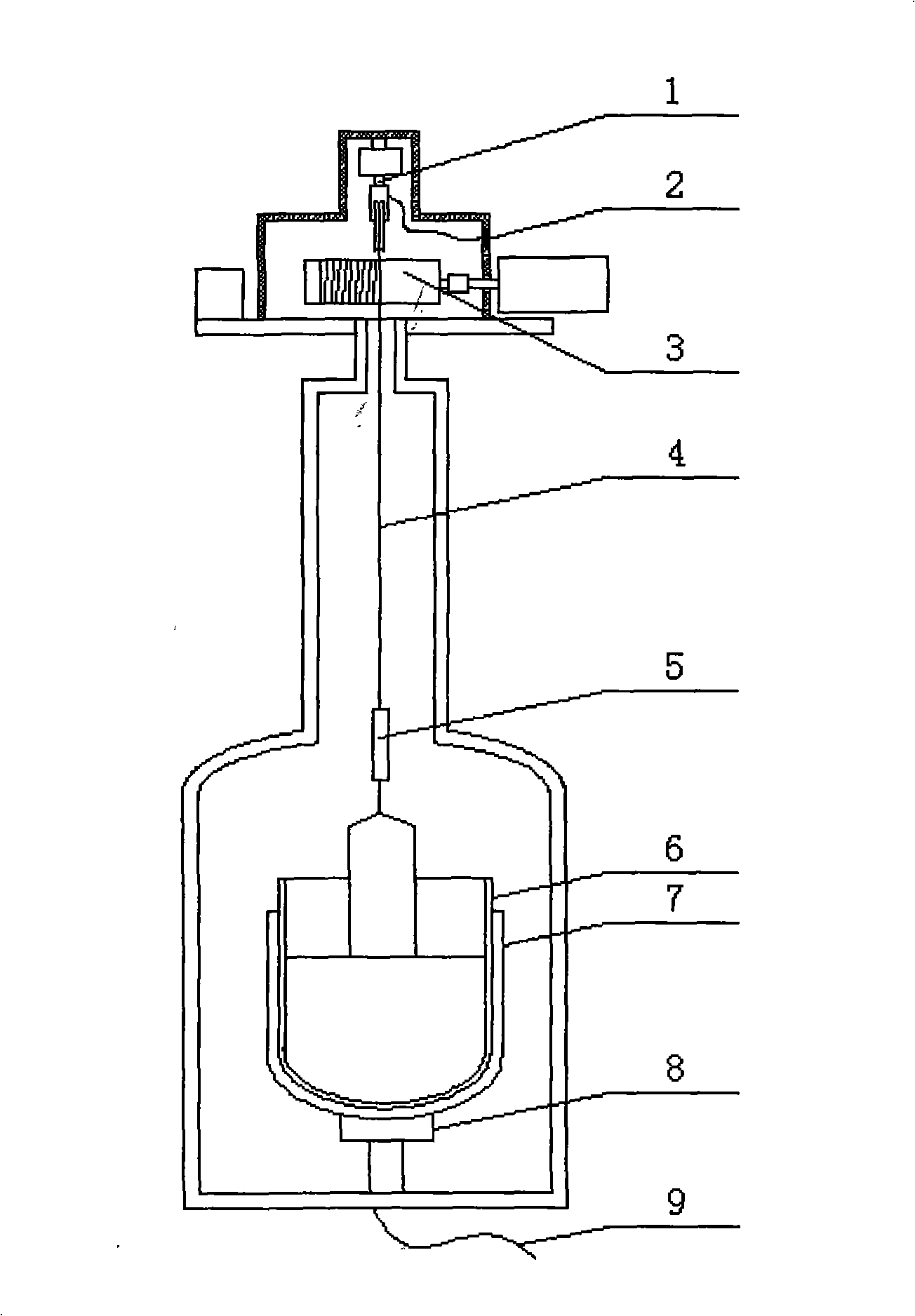

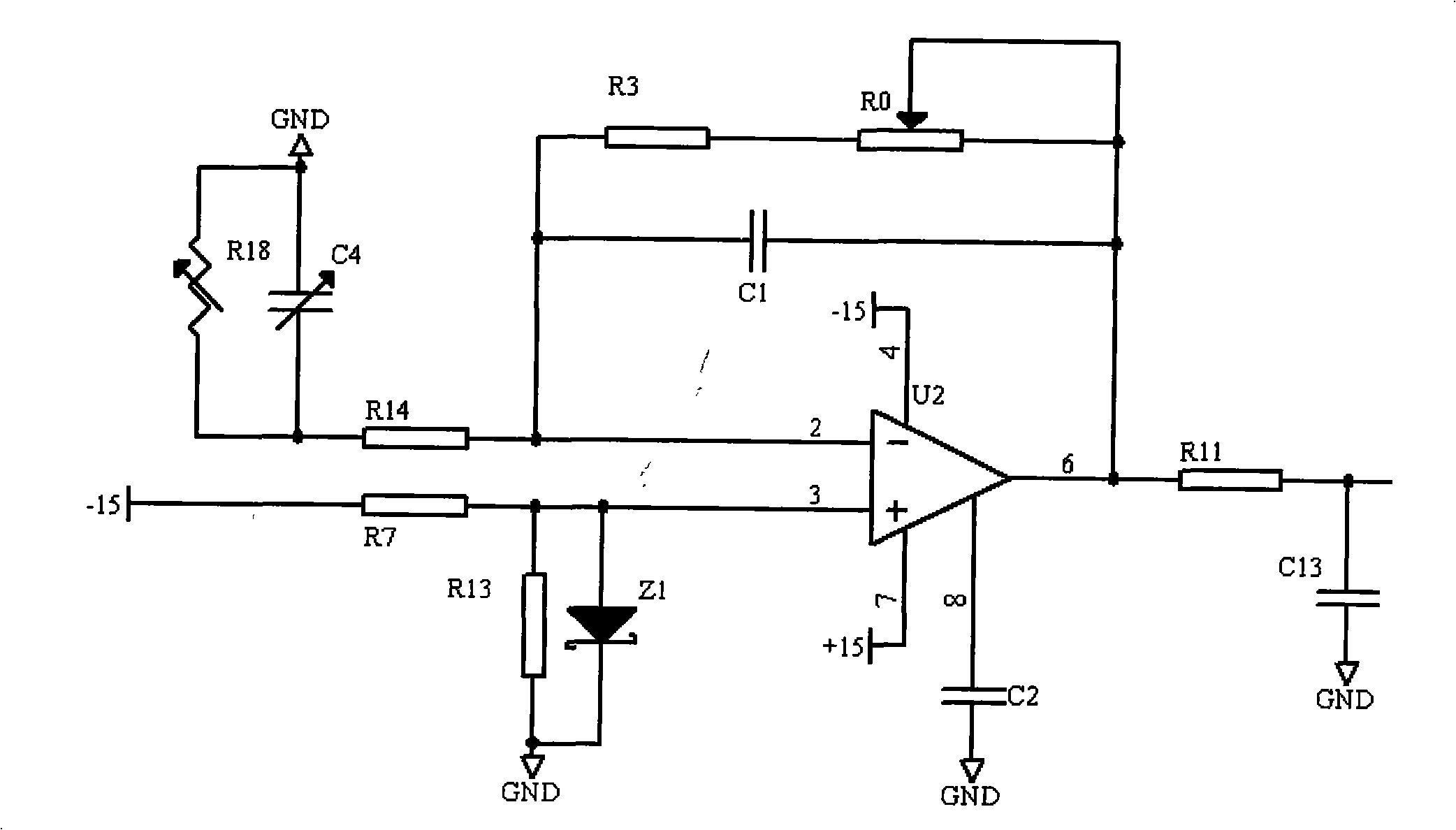

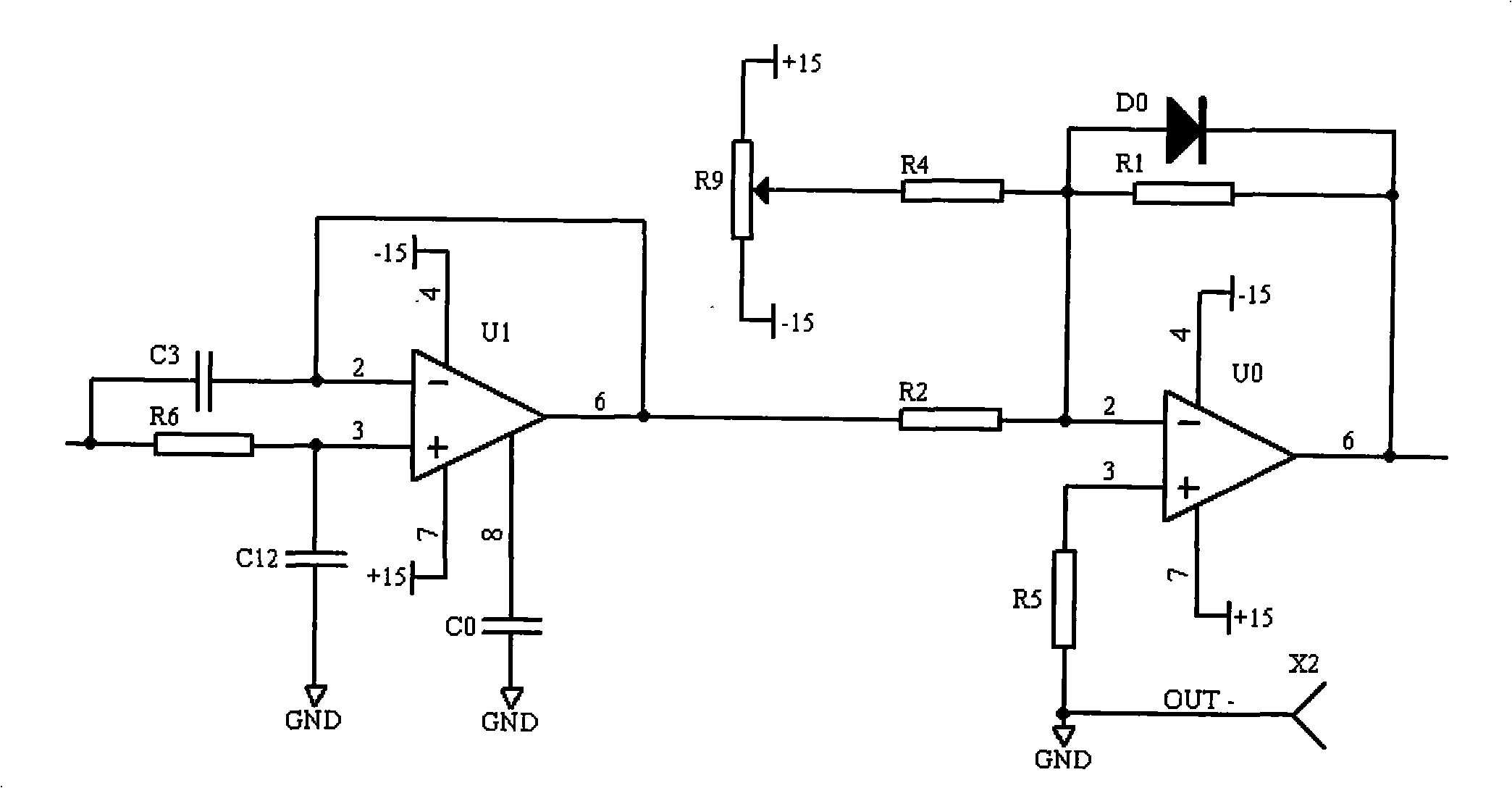

[0018] Referring to the accompanying drawings, the present invention will be described in detail below.

[0019] The invention designs a steel wire rope with insulation performance, so that the steel wire rope is electrically insulated from the pulley, the lifting drive mechanism and other components of the quartz crucible through an insulated cable tube. The crystal is connected to the steel wire rope through the seed crystal chuck, and is electrically conductive, while the silicon in the molten state is conductive, and there is a contact resistance between the liquid surface and the quartz crucible furnace body. When the crystal is not in contact with the molten silicon liquid surface, there is a large insulation resistance between the seed chuck and the quartz crucible furnace body, and when it touches the liquid surface, the insulation resistance changes to a small contact resistance; on the other hand, When the crystal is not in contact with the molten silicon liquid surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com