Diameter measurement method for straight pulling single crystal

A diameter measurement, single crystal technology, applied in the direction of single crystal growth, chemical instruments and methods, self-melt pulling method, etc., can solve the problems of low calculation accuracy, noise interference, complicated operation, etc., to improve calculation accuracy, operation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

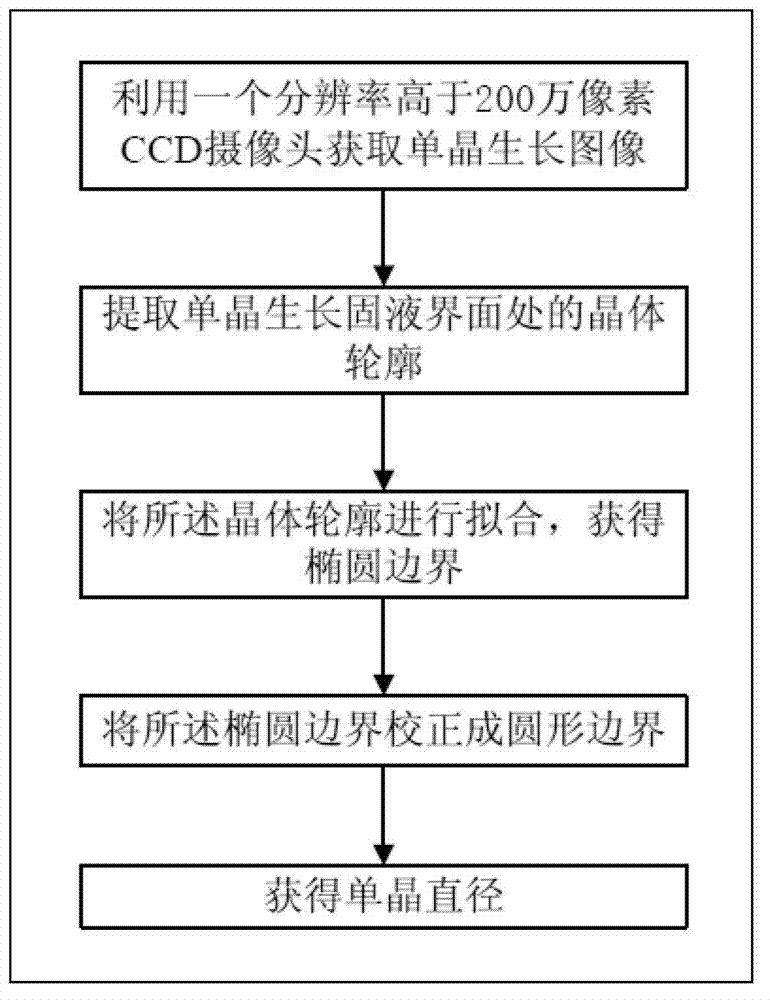

[0030] Examples, see figure 1 , a method for measuring the diameter of a Czochralski single crystal, comprising the following steps:

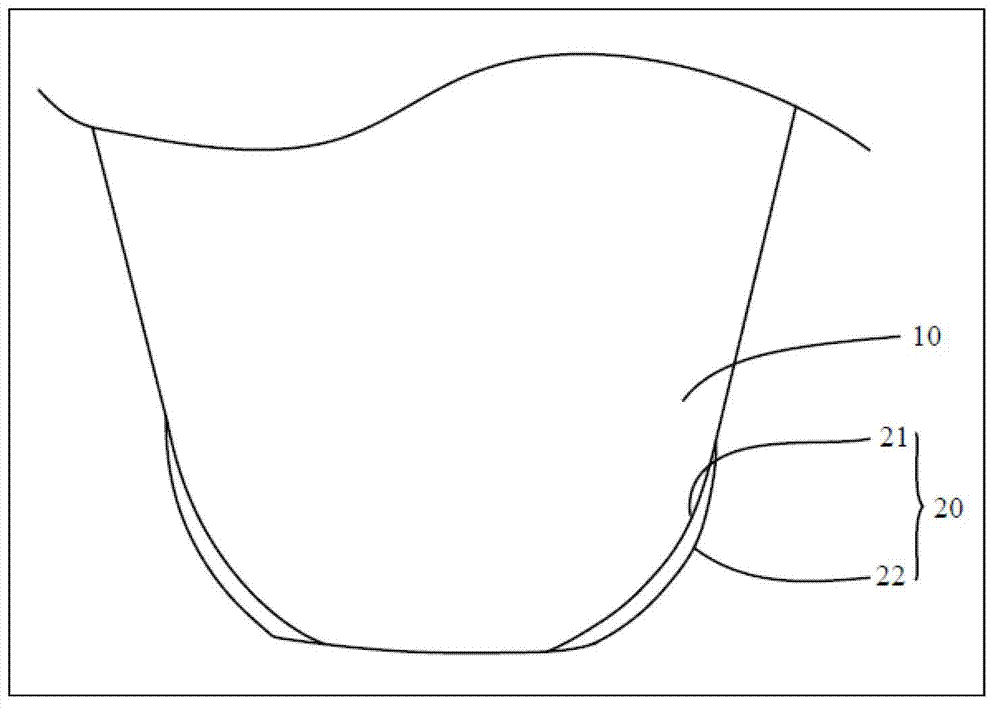

[0031] In the first step, a CCD camera with a high resolution of 2 million pixels is used to obtain images of single crystal growth. Specifically, there is a certain angle between the optical axis of the CCD camera and the liquid surface of the melt in the crucible, and the angle is not equal to 90°. refer to figure 2 , in the single crystal growth image acquired during the isometric growth process, there is a bright ring 20 at the solid-liquid interface below the single crystal 10 . The bright ring 20 includes an inner edge 21 close to the single crystal 10 and an outer edge 22 close to the melt side. figure 2 In the figure, due to the influence of the shooting angle and the structure of the single crystal furnace, the bright ring 20 is partially blocked.

[0032] In subsequent steps, the image of the single crystal growth is input to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com