A megasonic electroforming device and method for improving the uniformity of metal micro-electroforming

A micro-electroforming and equipment technology, applied in electroforming, electrolytic components, electrolytic process, etc., can solve problems such as uneven casting layer thickness, achieve high energy utilization rate, good electroacoustic conversion efficiency, and improve dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the embodiments shown in the accompanying drawings.

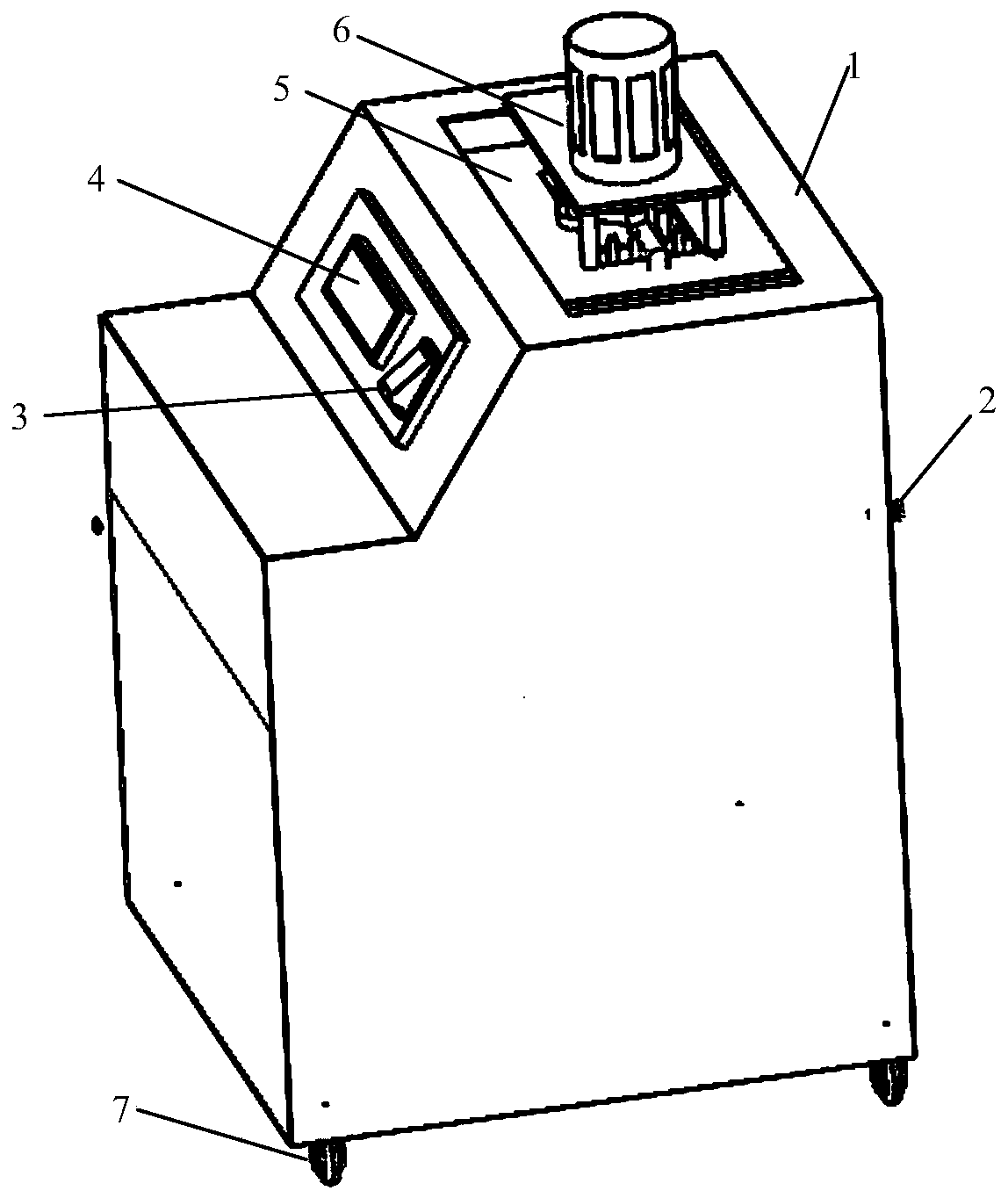

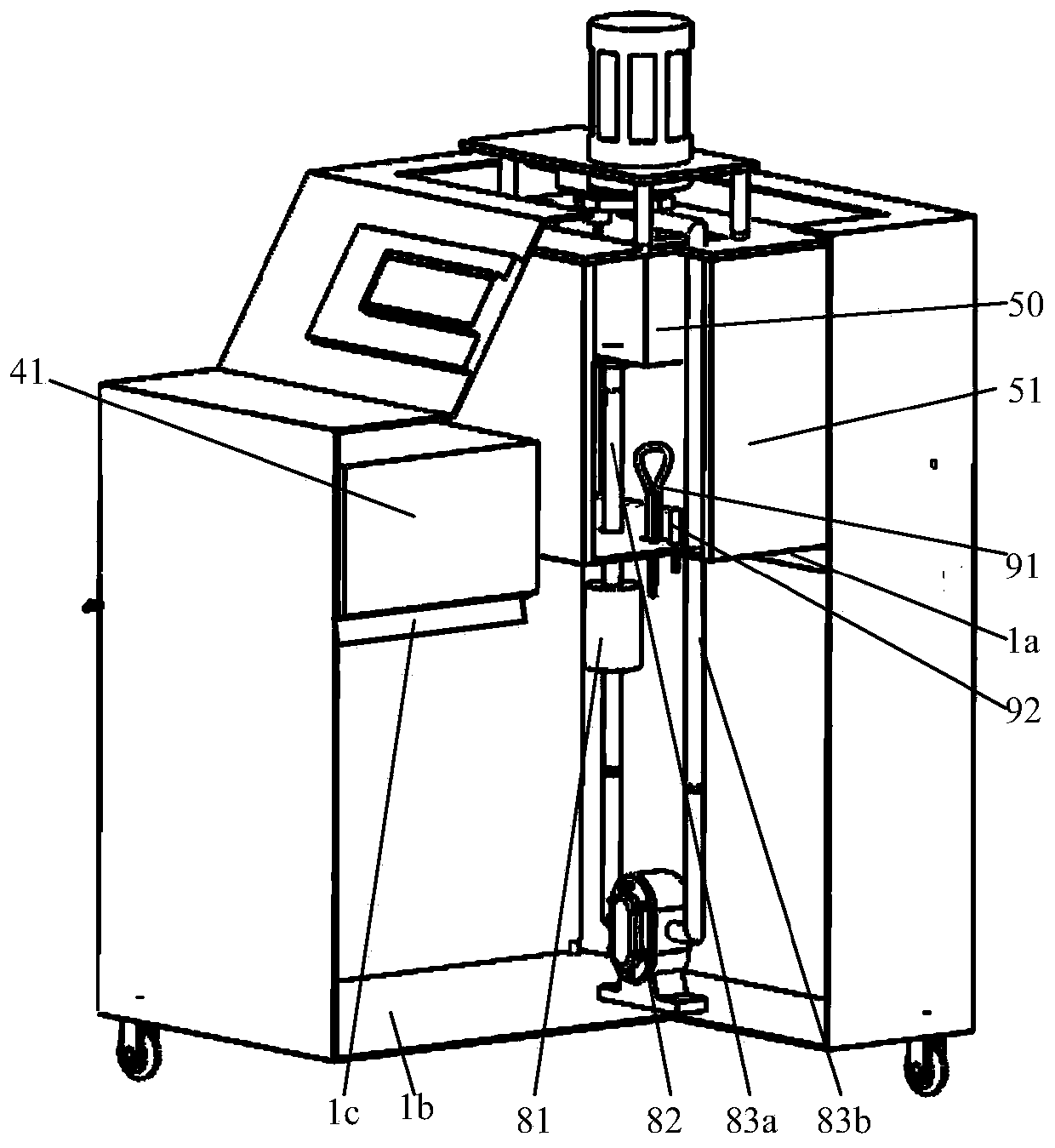

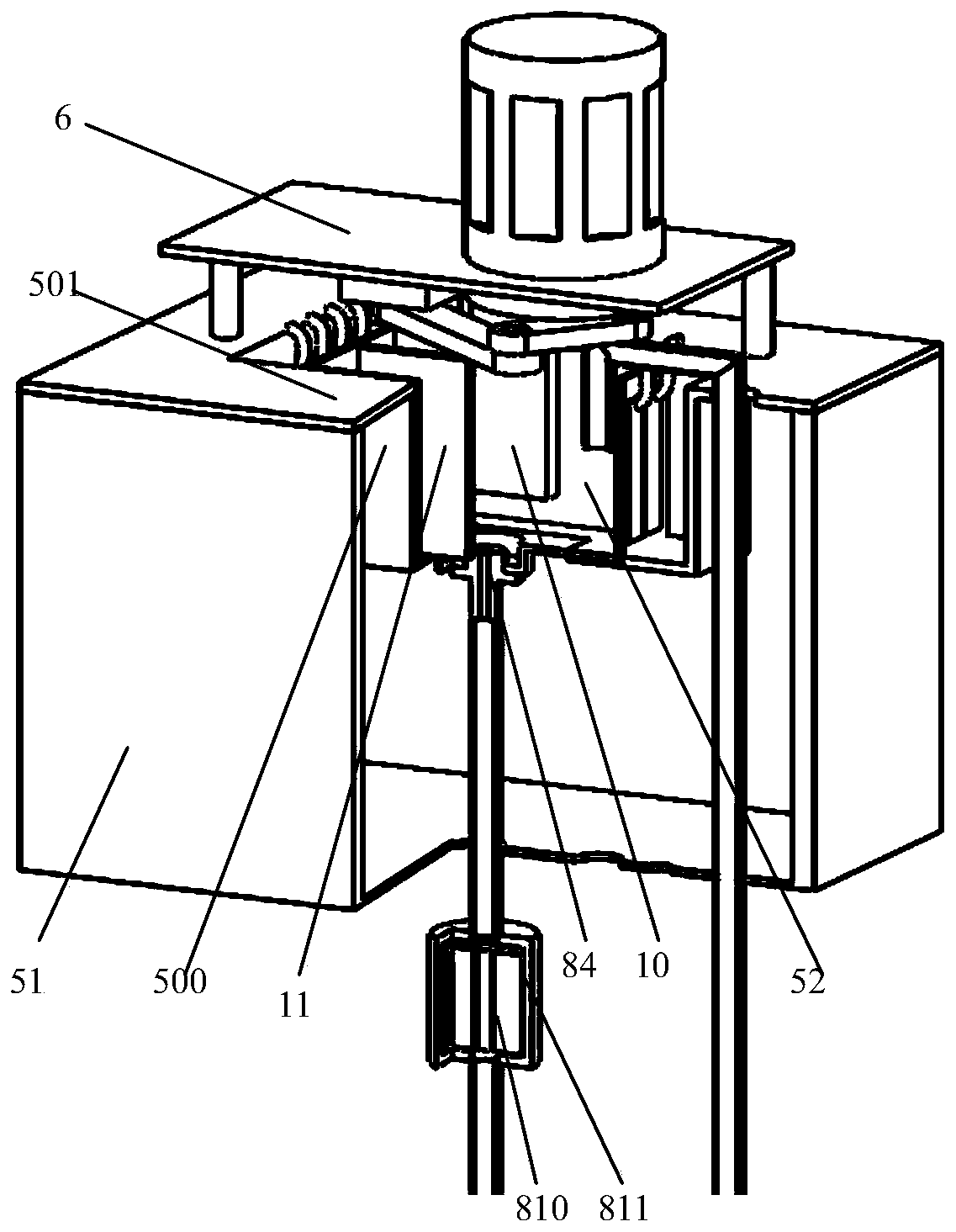

[0029] A megasonic electroforming equipment structure that improves the uniformity of metal micro-electroforming figure 1 , 2shown. It includes: equipment shell 1, power interface 2, main switch 3, control and display 4, power control box 41, megasonic casting tank 5, stirring mechanism 6, wheels 7, and filter 81, liquid circulation pump 82, liquid circulation Tube 83 and so on. The megasonic casting tank 5 is composed of a megasonic tank 50 and a water bath 51, the water bath is fixed on the support frame A1a, an electric heating tube 91 and a thermocouple 92 are arranged between the megasonic tank and the water bath, and they are fixed at the bottom of the water bath 51 . The circulation pump 82 is placed on the bottom plate 1b of the housing. The liquid circulation pipe A83a passes through the megasonic tank 50 and the water b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com