Metal stripped material uncoiling, buffer storage, straight pulling and shearing positioning device

A technology of positioning device and unwinding device, which is applied in thin material handling, transportation and packaging, sending objects, etc., to achieve the effect of improving operation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

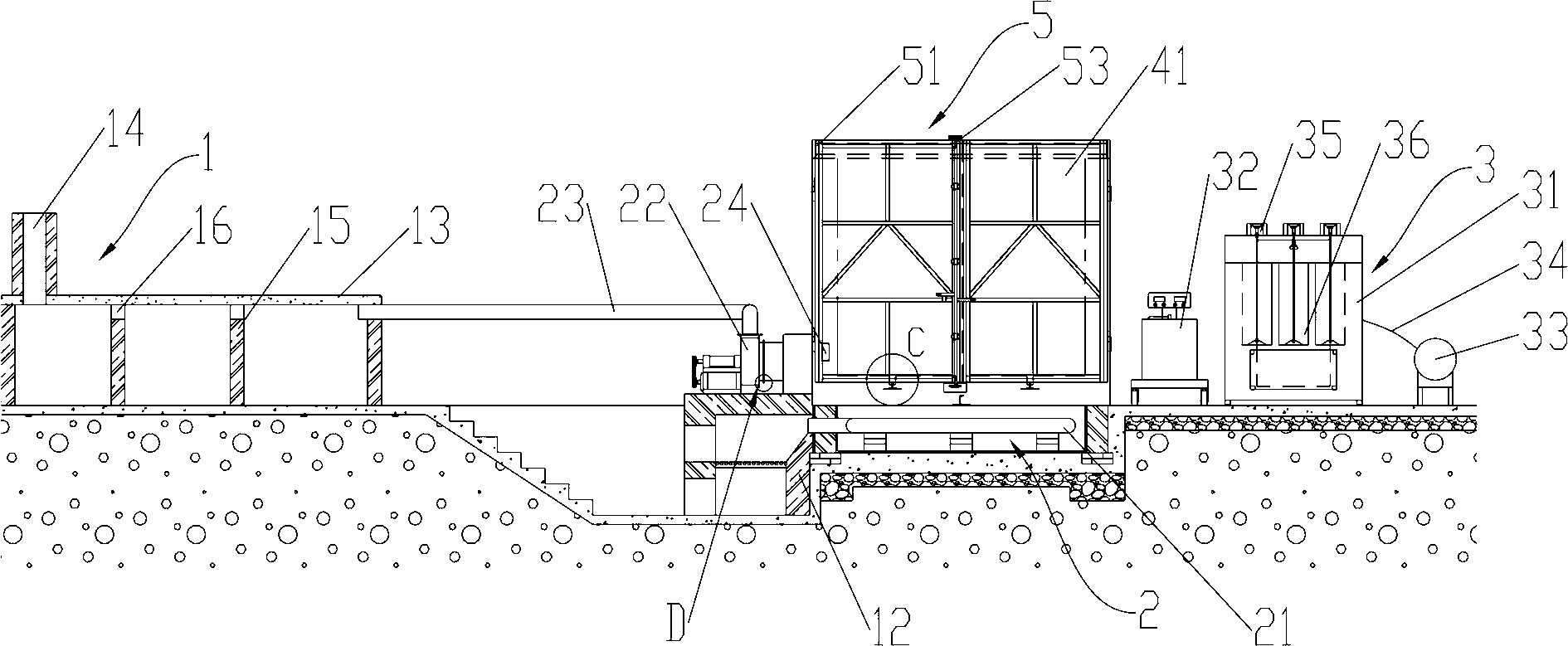

[0033] Unwinding, buffering, straightening, shearing and positioning devices for metal strip materials, such as figure 1 As shown, it includes a ribbon unwinding device 1, a buffer device 2, a reversing roller 3, a flux dipping device 4, a flux drying device 5, and a ribbon finishing device 6, as well as an air gripping device 7 and a ribbon guiding device. 8, of which,

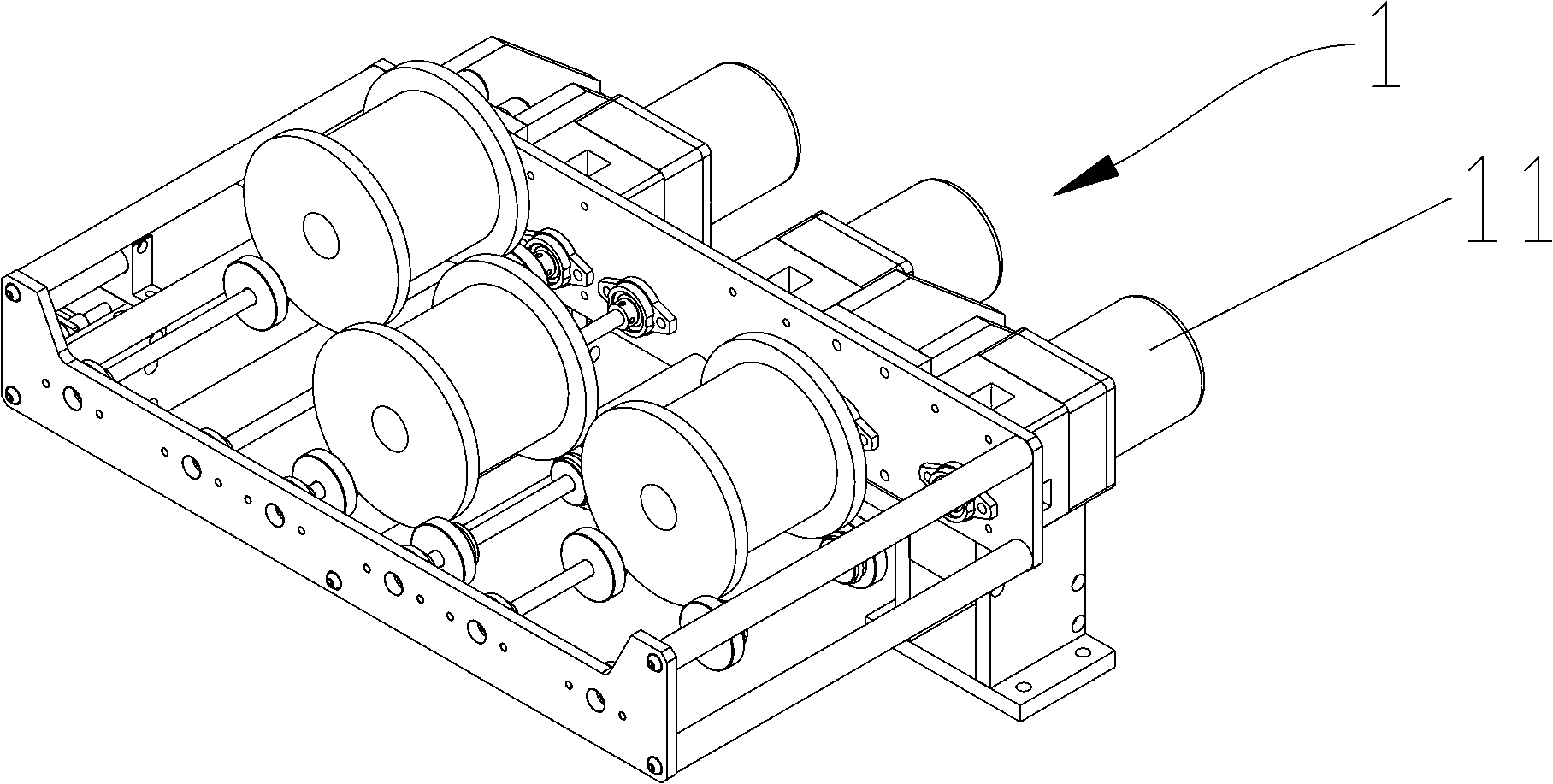

[0034] The ribbon unwinding device 1, such as figure 2 As shown, it includes a reversible motor 11 for releasing the crimped ribbon;

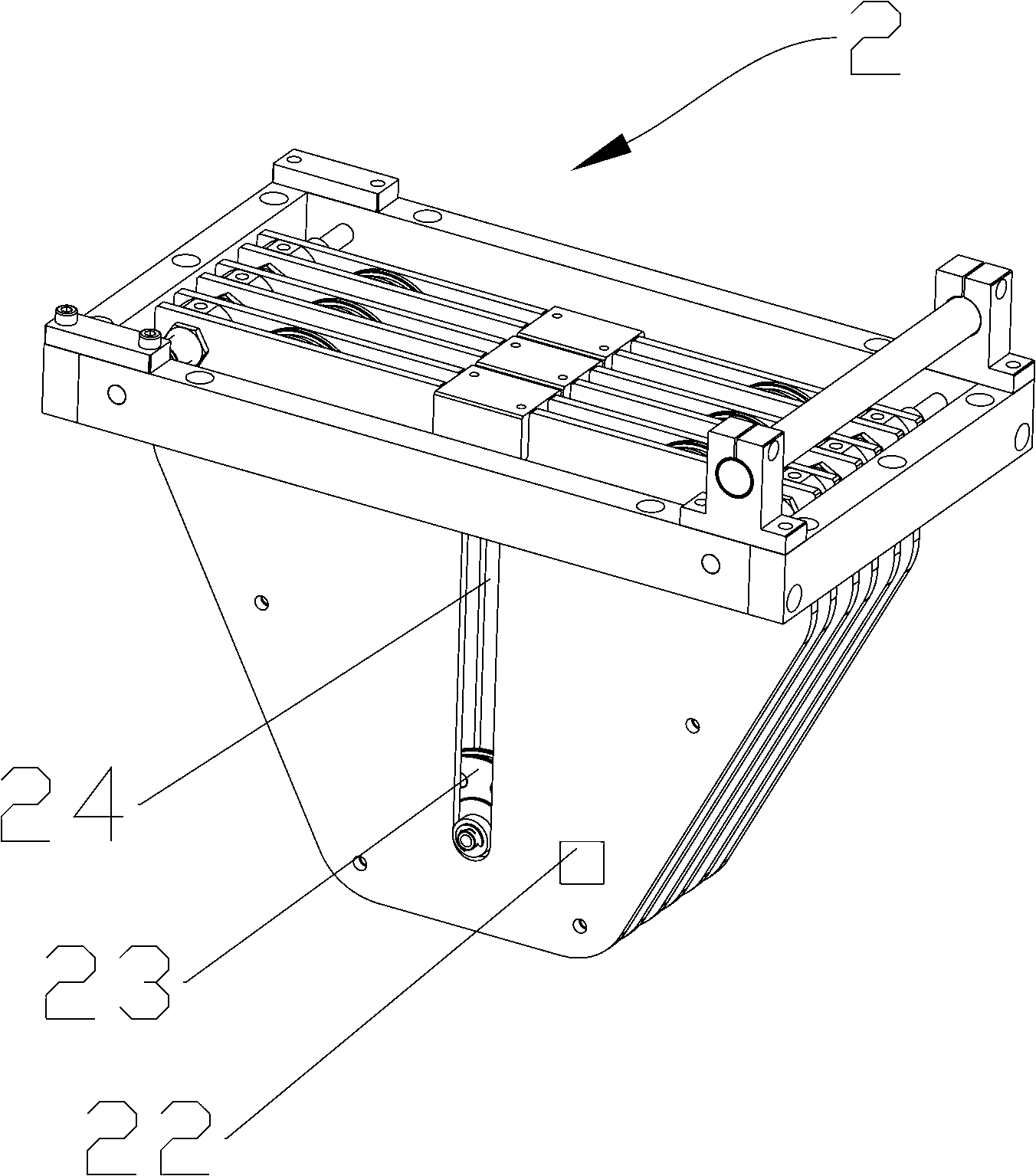

[0035] The cache device 2, such as image 3 As shown, it is located downstream of the ribbon unwinding device 1 , including a ribbon tension counterweight roller 23 and a photoelectric sensor 22 , wherein the ribbon tension counterweight roller 23 can move up and down along a channel 24 vertically arranged in the middle of the buffer device 2 , the photoelectric sensor 22 is facing the lower end of the through slot 24 to monitor the position of the ribbon tension counterwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com