Silicon seed crystal holder for monocrystal silicon by vertical pulling process

A technology for growing monocrystalline silicon and seed crystal clips, which is applied in the field of silicon seed crystal holders for growing monocrystalline silicon by the Czochralski method. Processing costs, avoiding breakage, and ensuring the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

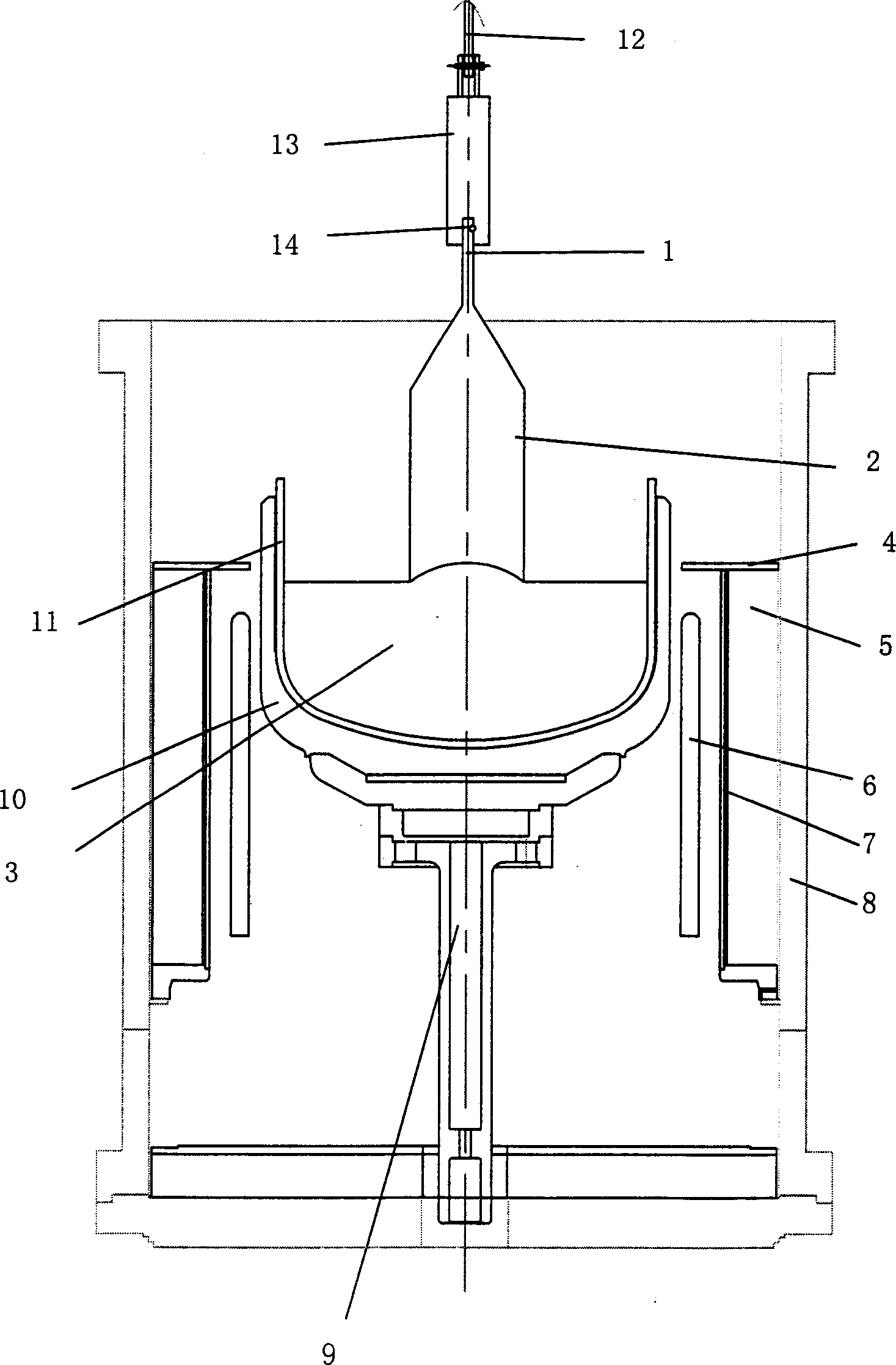

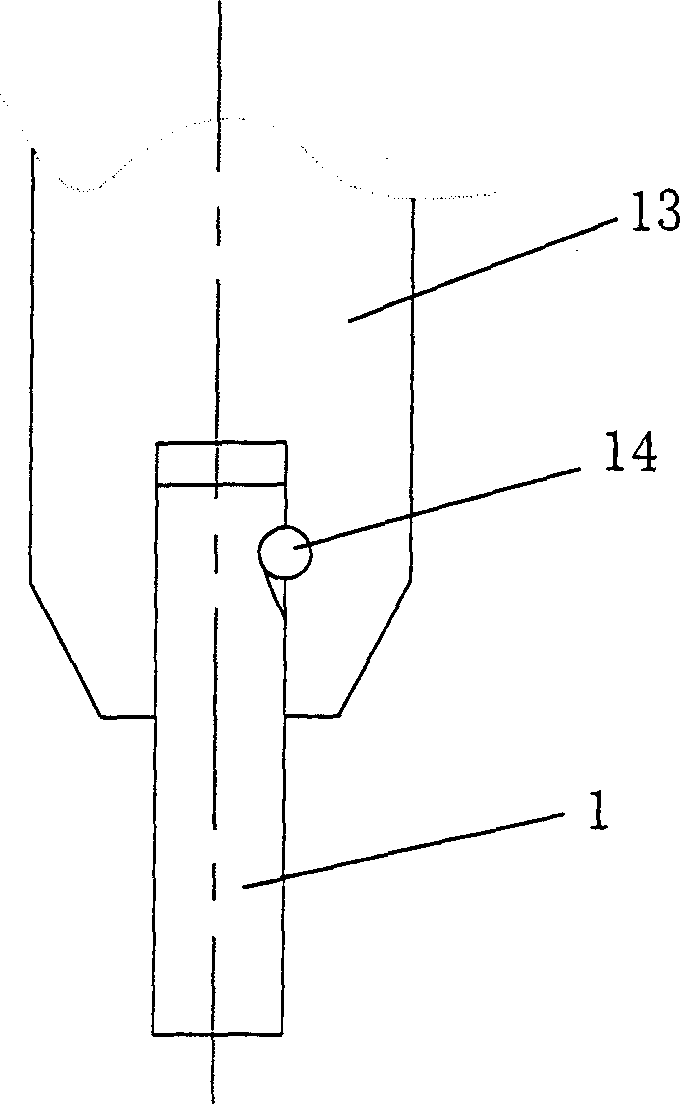

[0038] Figure 4 Shown is a cross-sectional view of the silicon seed holder according to the present invention. The silicon seed crystal holder of the present invention includes a coupling member 13c connected with the seed crystal shaft 12, a holder upper part 13a and a holder lower part 13b which are integrally connected with the coupling member, and the holder lower part 13b is A cylindrical body with cavities penetrating through the upper part and the lower part, and the upper part 13a of the holder is a cylindrical body.

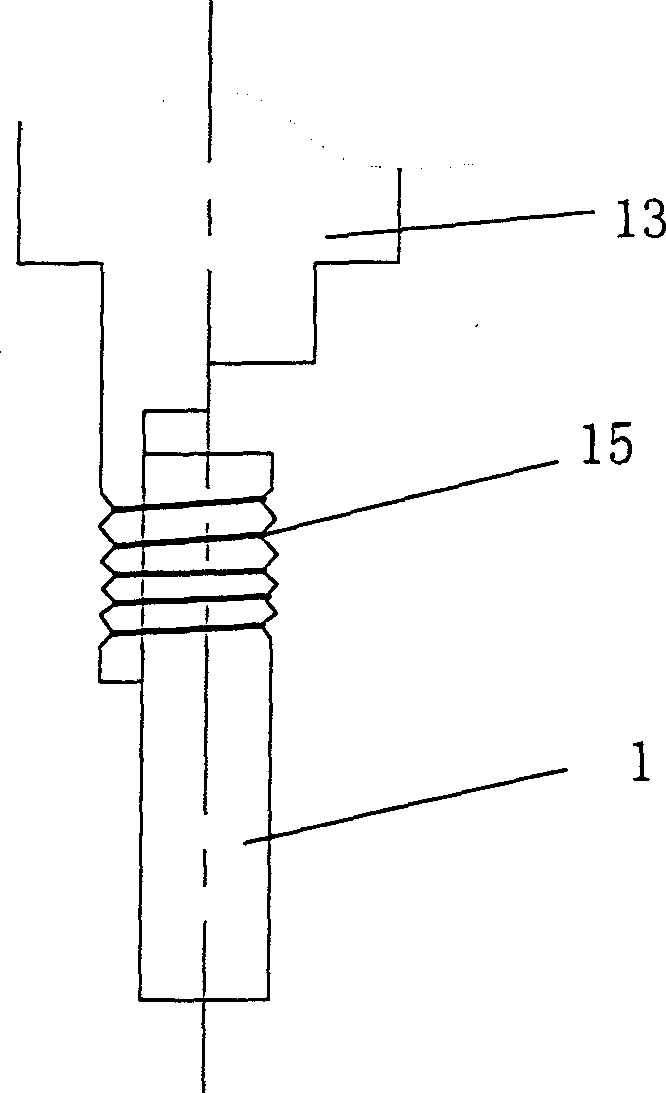

[0039] The upper part 13a of the holder and the lower part 13b of the holder are threadedly connected, the connecting piece 13c connecting the holder and the seed crystal shaft 12 is a pin connection, and the connecting piece 13c is a double-ear structure .

[0040] The cavity of the lower part 13b of the holder is a rounded table hole and a cylindrical hole, and the angle θ between the side of the rounded table hole and the shaft is 15°.

[0041] Figure ...

Embodiment 2

[0044] Figure 7 Shown is a cross-sectional view of the lower part 13b of another silicon seed holder of the present invention. The difference from Embodiment 1 is that the cavity in the lower portion 13b of the holder is a rounded platform.

Embodiment 3

[0046] Figure 8 Shown is another cross-sectional view of the lower part 13b of the silicon seed holder of the present invention. The difference from Embodiment 1 is that the cavity of the lower part 13b of the holder is two stepped cylindrical holes, and the hole diameter of the upper cylindrical hole is larger than the hole diameter of the lower cylindrical hole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com