A straight pull display and a pressing method thereof

A display and straight-pull technology, which is applied in the direction of electrical components, electrical components, instruments, etc., can solve the problems of uncertain binding status of IC panel and display panel, poor light transmission, etc., and achieve the effect of preventing breakage and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

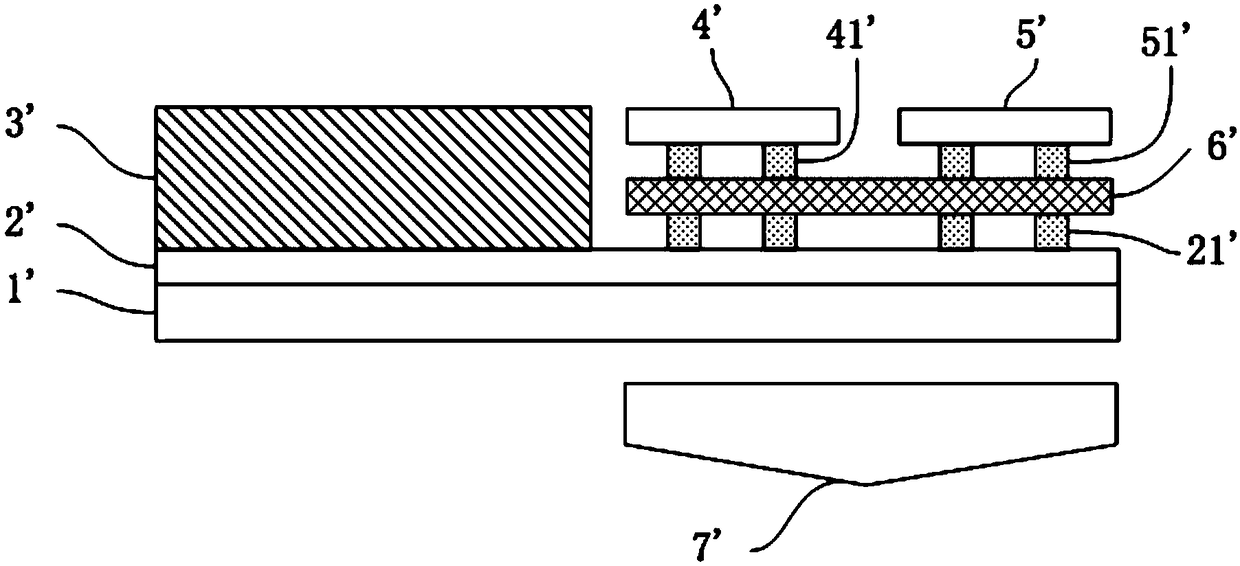

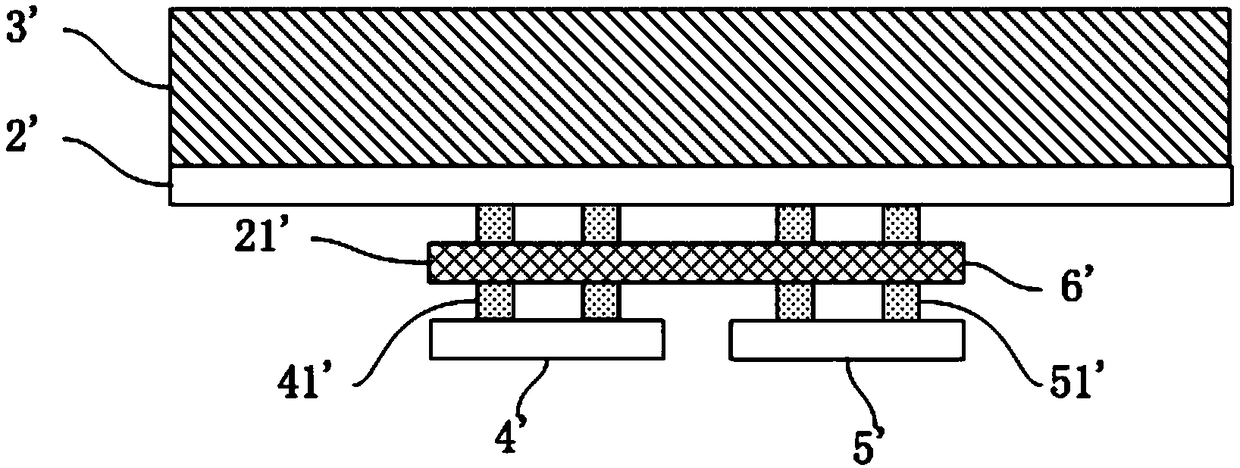

[0037] The invention provides a lamination method of a straight-pull display screen, the lamination method comprising the following steps:

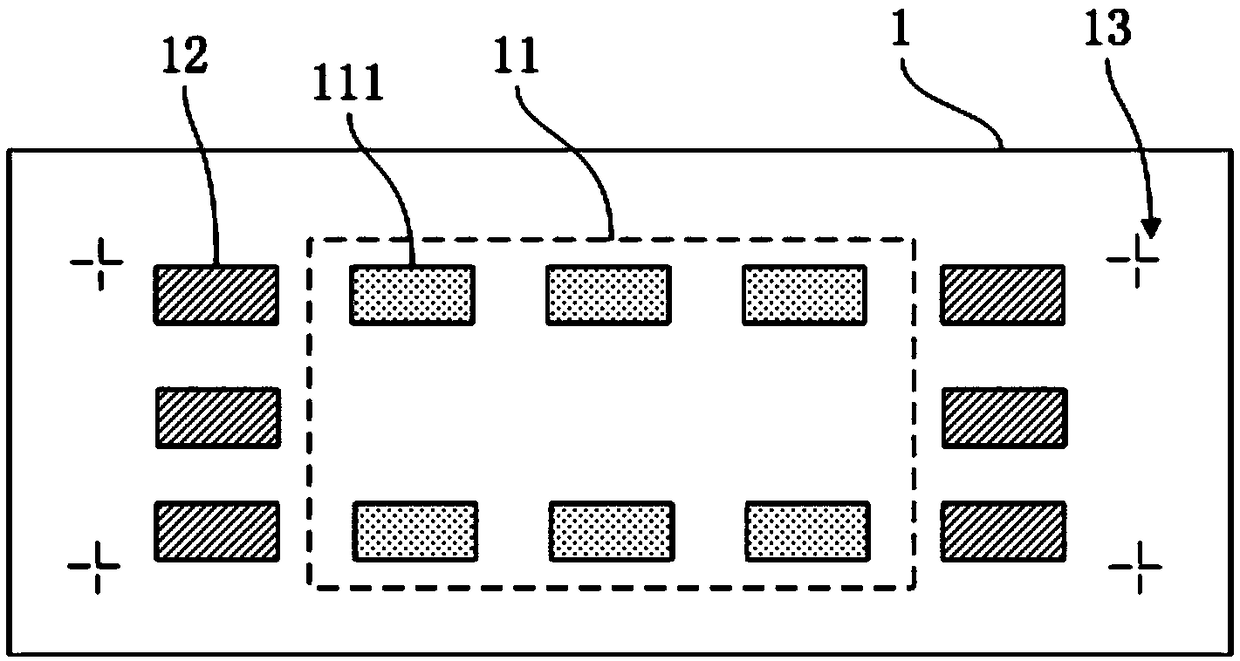

[0038] Such as image 3 As shown, at least two first conductive blocks 12 are formed on the display panel 1, as Figure 4 As shown, at least two second conductive blocks 22 for alignment with at least two first conductive blocks 12 are formed on the IC (integrated circuit) panel 2, and at least two first conductive blocks 12 are used as the display panel 1 The alignment mark of the binding area 11, at least two second conductive blocks 22 are used as the alignment mark of the binding area 21 of the IC panel 2; there are a plurality of binding terminals 111 in the binding area 11, and there are A plurality of binding terminals 211 .

[0039] Such as Figure 5 As shown, conductive glue 3 is coated on the bonding area 11 of the display panel 1 , and insulating glue 4 is coated on at least two first conductive blocks 12 ; there is a gap be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com