An electrohydraulic power steering system controlled based on vehicle speed and load signals

A technology of hydraulic power steering and load signal, which is applied in the direction of electric steering mechanism, steering mechanism, steering rod, etc., which can solve the problems of unstable steering system and control unit operation that cannot be changed according to external information, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

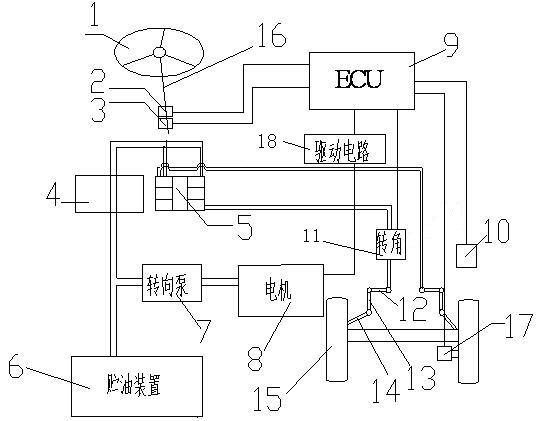

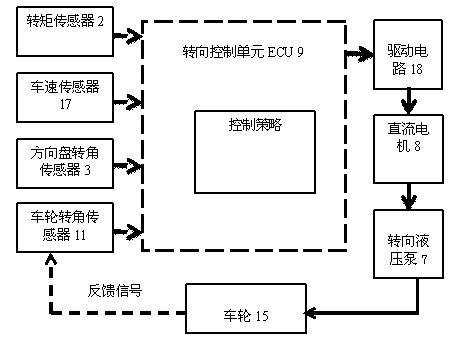

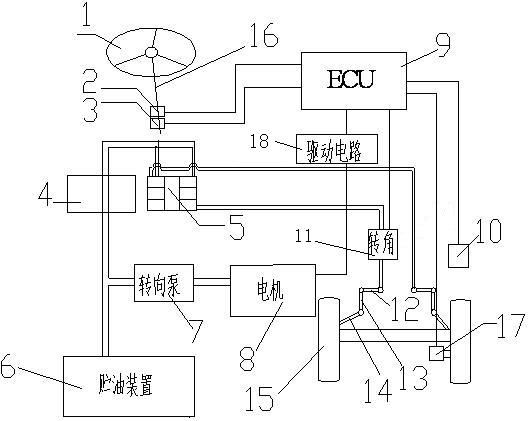

[0011] see figure 1 , the present invention includes a steering control unit 9 for controlling the actuator, a DC motor 8, a steering hydraulic pump 7, an oil storage device 6 and a power steering cylinder 5. The steering hydraulic pump 7 is connected between the oil storage device 6 and the DC motor 8; the steering hydraulic pump 7 is connected with the rotary valve 4, and the rotary valve 4 is connected with the steering power cylinder 5, the steering fluid flows through the steering valve 4, and the steering valve 4 is controlled by the steering Controlled by the unit 9, the steering valve 4 controls the pushing direction of the power steering cylinder 5 to realize pushing in different directions. The DC motor 8 is connected to the steering control unit 9 through a drive circuit 18 . The oil storage device 6 provides steering fluid to the steering hydraulic pump 7, and the drive circuit 18 controls the rotation speed of the output shaft of the DC motor 8. The output shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com