Cross-flow fan

A cross-flow fan and cross-flow wind wheel technology, which is applied in the direction of mechanical equipment, radial flow pumps, machines/engines, etc., can solve problems such as poor flow field characteristics, large gap between the wind wheel and the volute, and unstable flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

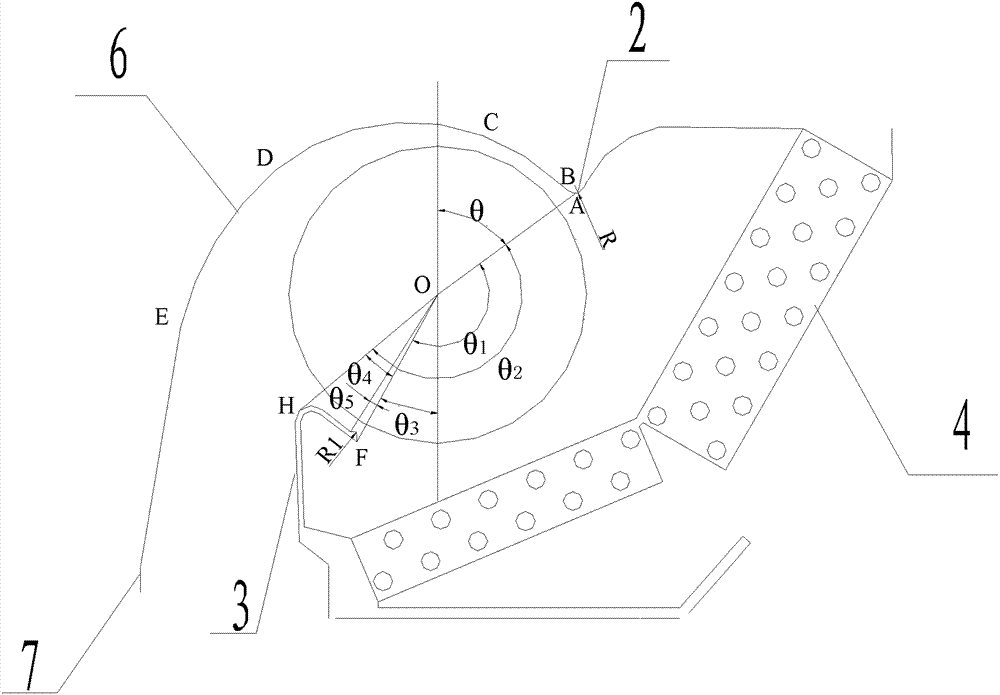

[0032] Such as Figure 3-4 As shown, the structural parameters of this embodiment mainly include the following points, the tangent point between the sectional curve of the rear volute tongue 2 and the horizontal plane is point A, and the end point of the sectional curve of the front volute tongue 3 near the end of the air inlet is point F, Through the central point O of the cross-flow wind wheel 1, a tangent line that is tangent to the cross-sectional curve of the front volute tongue 3 intersects the cross-sectional curve of the front volute tongue 3 at point H, and the point A and the center vertical line of the cross-flow wind wheel 1 have The included angle θ=45°, the radius of curvature R=2.76mm of the section curve of the rear cochlear tongue 2. Angle θ between point A and point F with ∠AOF 1 =155°, the included angle θ of ∠AOH between point A and point H 2 =176°.

[0033] The angle θ between the line connecting the terminal point F of the anterior cochlear tongue 3 an...

specific Embodiment 2

[0038] Such as Figure 3-4 As shown, the structural parameters of this embodiment on the basis of Embodiment 1 have the following changes: the included angle θ=50° between the point A at the rear volute tongue 2 and the vertical line of the center of the cross-flow wind wheel 1, and the rear The radius of curvature R of the section curve of the volute tongue 2 is 3.49mm, and the included angle θ between point A and point H is ∠AOH 2 =177°; ∠BOA angle θ between the end point B and point A of the BC curve section near the air inlet side 6 =5°; the radius of curvature R of the boss 1 = 1.2 mm.

[0039] The CFD simulation speed vector diagram of the present embodiment is Figure 7 , the velocity distribution of the flow field is marked in the form of contour lines in the figure, and the number marks represent the flow velocity. It can be seen that the flow field is similar to that of Example 1, but the scale of the eccentric worm is relatively smaller than that of the prior art...

specific Embodiment 3

[0040] Such as Figure 3-4 As shown, the structural parameters of this embodiment have the following changes on the basis of Embodiment 1. The included angle θ=55° between the point A at the 2 points of the rear volute tongue and the vertical line of the center of the cross-flow wind wheel 1 is 55°. The curvature radius R of the volute tongue 2 section curve is 5.27mm, and the AOH angle θ between point A and point H 2 =177°; ∠BOA angle θ between the end point B and point A of the BC curve section near the air inlet side 6 =5°; the radius of curvature R of the boss 1 = 1.15 mm.

[0041] The CFD simulation speed vector diagram of the present embodiment is Figure 8 , the velocity distribution of the flow field is marked in the form of contour lines in the figure, and the numerical marks represent the flow velocity. It can be seen that the scale of the eccentric worm is relatively smaller, the effective flow area of the cross-flow rotor 1 is increased, and the flow field at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com