Polypropylene composite material as well as preparation method and application thereof

A technology of composite materials and polypropylene, which is applied in the application field of polypropylene composite materials and its preparation, and the preparation of seamless automotive dashboards, can solve the problems affecting the appearance of the whole vehicle, and achieve broad market prospects, excellent low-temperature impact performance, The effect of low VOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

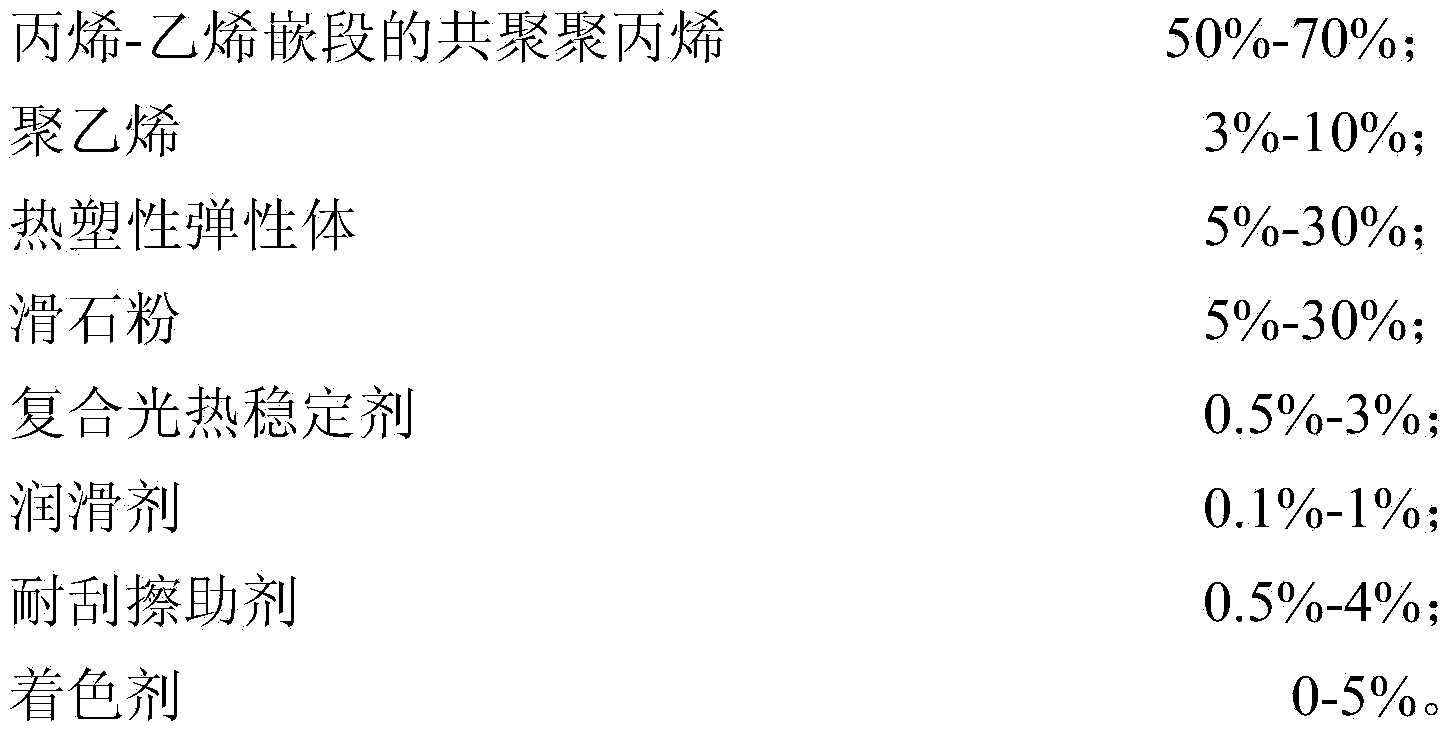

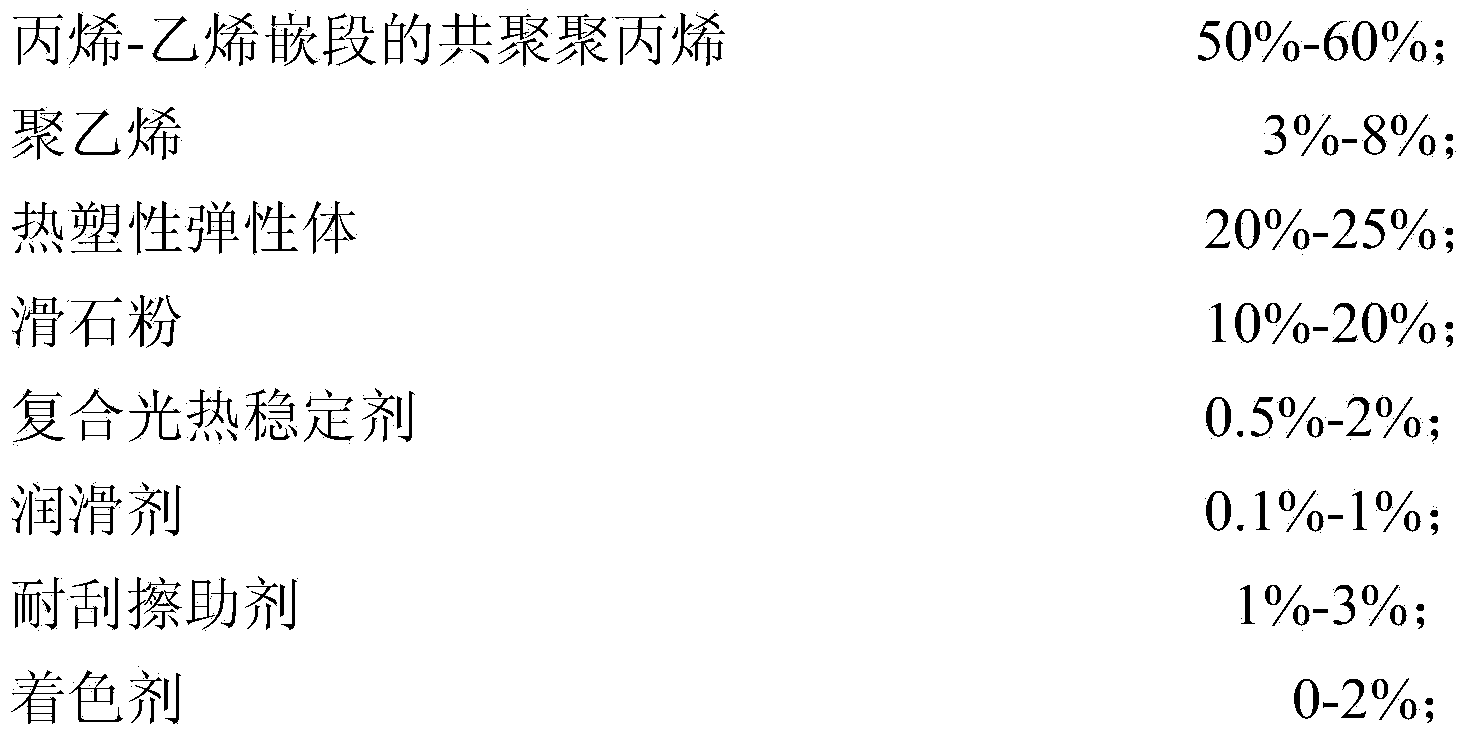

Method used

Image

Examples

Embodiment 1~5

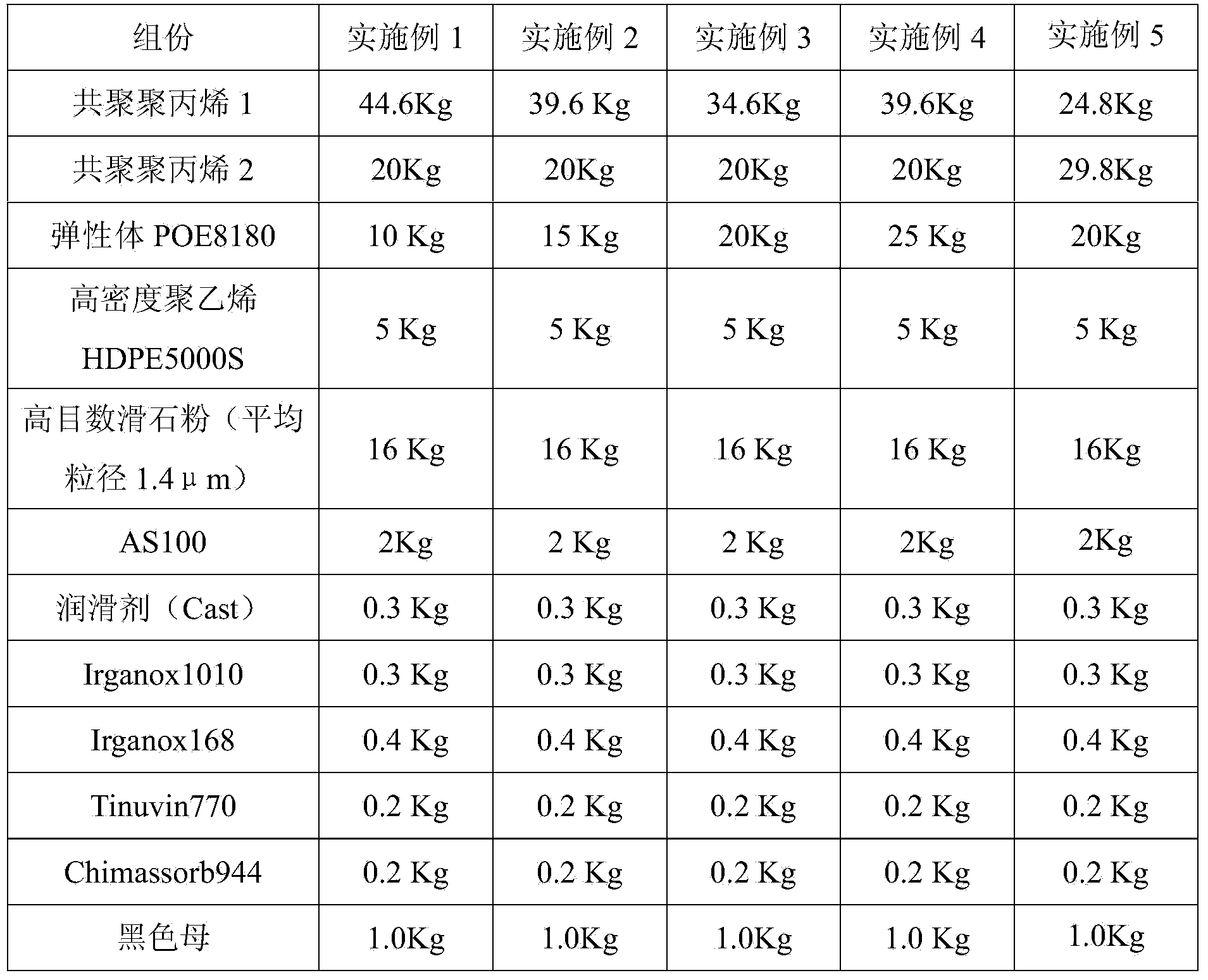

[0038] The components such as copolymerized polypropylene (that is, the copolymerized polypropylene of propylene-ethylene block), polyethylene, talcum powder, thermoplastic elastomer, anti-scratch additive, lubricant, composite light and heat stabilizer are in parts by weight in Table 1 The proportioning ratio is mixed evenly in the mixer to obtain the mixed material. The mixed material is fed into the twin-screw extruder from the feeder. The temperature of the twin-screw extruder from the feeding section to the head is as follows: 190°C, 210°C, 220°C, 220°C, 220°C, 220°C, 220°C, 230°C, the temperature of the die is: 230°C. After high-speed twin-screw extruder (screw speed: 800r / min), shearing and mixing, extruding from the machine head, drawing, air cooling, pelletizing, drying and packaging, the polypropylene composite product is obtained.

[0039] Table 1

[0040]

[0041] The source of raw material used among the embodiment 1~5 and main performance index are as table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com