Method for manufacturing high-strength steel plate used in low-temperature environment

A technology of high-strength steel plate and manufacturing method, applied in the direction of temperature control, manufacturing tools, metal rolling, etc., can solve problems such as low ambient temperature, and achieve the effects of improving comprehensive mechanical properties, improving welding adaptability, and large safe use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] According to the chemical composition range of the present invention, a steel plate with a thickness of 10 mm is produced on a wide and thick plate production line. After heat treatment, the performance of the steel plate is excellent, its chemical composition is shown in Table 1, the controlled rolling and cooling process is shown in Table 2, the heat treatment process parameters are shown in Table 3, and the mechanical properties of the steel plate are shown in Table 4.

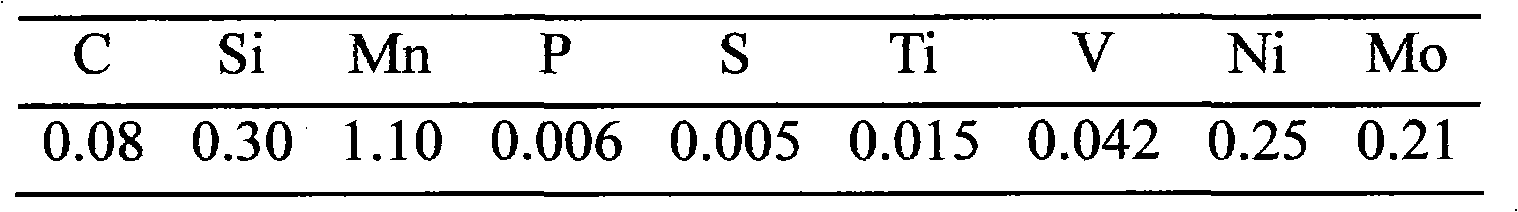

[0016] Table 1 embodiment measured chemical composition (mass fraction %, all the other are Fe)

[0017]

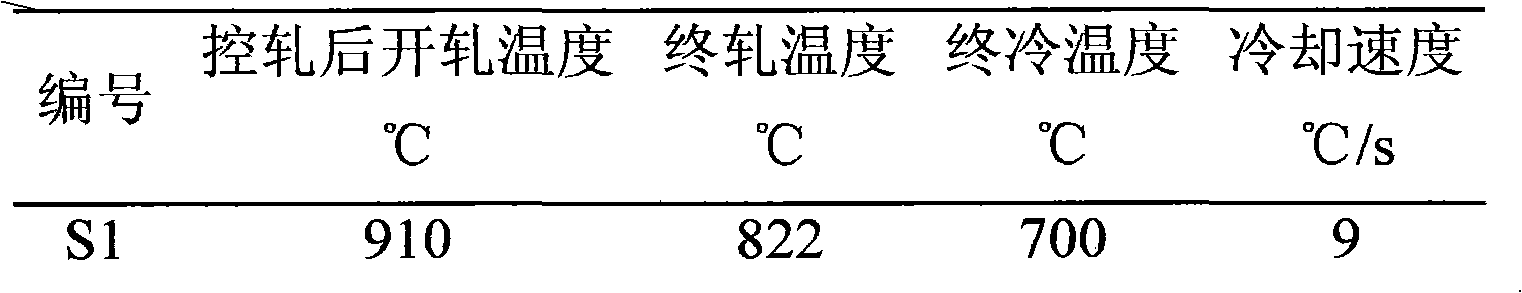

[0018] Table 2 embodiment 1 controlled rolling and controlled cooling process parameters

[0019]

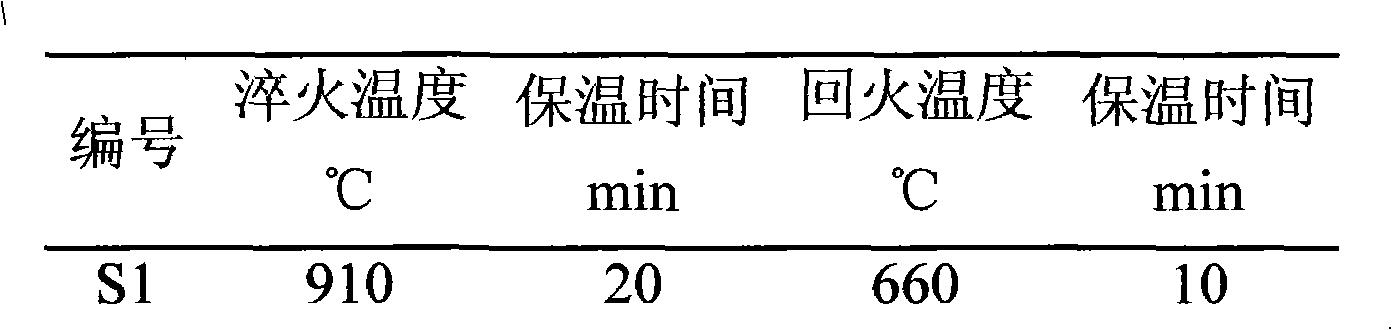

[0020] Table 3 embodiment 1 heat treatment process parameter

[0021]

[0022] Table 4 Example 1 product mechanical properties

[0023]

[0024] The steel plate has excellent low-temperature impact performance at -60°C, and its ductile-brittle transition temperature is -85°C, which e...

Embodiment 2

[0026] According to the chemical composition range of the present invention, a steel plate with a thickness of 60 mm has been produced on the wide and thick plate production line. After heat treatment, the performance of the steel plate is excellent. Its chemical composition is as shown in Table 5, and the controlled rolling and cooling process is as shown in Table 6. The heat treatment process parameters are shown in Table 7, and the mechanical properties of the steel plate are shown in Table 8.

[0027] Table 5 Example 2 measured chemical composition (mass fraction %, the rest is Fe)

[0028]

[0029] Table 6 embodiment 2 controlled rolling and controlled cooling process parameters

[0030]

[0031] Table 7 embodiment 2 heat treatment process parameters

[0032]

[0033] Table 8 Example 2 product mechanical properties

[0034]

[0035] The 60mm thick steel plate in Example 2 also has excellent low-temperature impact performance at -60°C at different positions, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com