Back non-filling argon self-protective heat-resistant steel argon tungsten-arc welding flux-cored wire

A technology of argon tungsten arc welding and flux-cored welding wire, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems that the welding quality cannot be guaranteed, double-sided welding cannot be performed, and labor intensity is high. Achieve the effect of excellent welding process performance, exempt from cumbersome process measures, and good welding adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

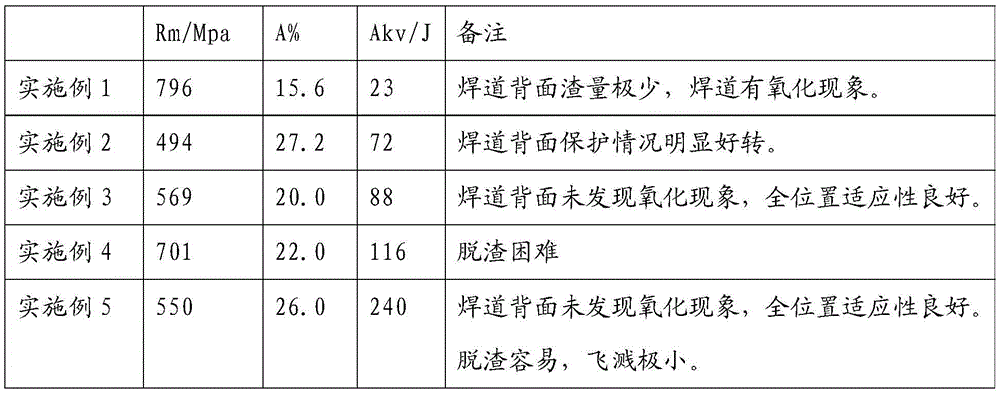

[0049] See from embodiment: embodiment 1, TiO 2 And the percentage of X content is low, resulting in no slag coverage on the back of the weld bead, resulting in oxidation of the weld bead. The content percentage of C, Si and Ti in the alloy elements is higher, resulting in higher strength and lower plasticity and toughness values. Example 2, TiO 2 And the percentage of X content is greatly increased, and there is less oxidation on the back of the weld bead. The content percentage of C and Si in the alloying elements is low, resulting in low strength but significantly improved plasticity and toughness. In Example 3, the content percentages of each element were preliminarily adjusted in place, and all indicators of mechanical properties were good. Embodiment 4, each index of mechanical property is better, TiO 2 And the higher percentage of X content causes thicker slag in the welding layer, and it is difficult to remove the slag, which cannot meet the requirements of on-site...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com