3ni-1.6cr-0.5mo welding rod for supporting steel for nuclear power equipment and its preparation method

A welding rod and equipment technology, applied in the field of high-strength welding rods, can solve the problem that welding materials are not easy to obtain, and achieve the effects of good welding adaptability, smooth welding rod surface and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Example 1, a high-alkalinity and low-hydrogen coating of this embodiment, the solid component and the liquid component in the coating are mixed, and the added weight of the liquid component is 20% of the weight of the solid component. %; The solid component comprises the following components in parts by weight: CaC0 45 parts of CaF 20 parts of TiO 7 parts of Na2CO 1 part of CaSiO 6 parts of MgO 3 parts of TiFe 6 parts of SiFe 2 parts of metal Ni powder 6 parts of metal Cr powder 4 parts ; The low alloy steel welding core used, the weight percentage of chemical composition measured by chemical analysis method: C 0.12%, Si 0.20%, Mn 1.8%, P0.008%, S0.003%, Cr1.6%, Ni 3.0%, Mo0.5%, Cu 0.01%, Co0.002%, B≤0.0005%, Nb≤0.01%, As 0.004%, Sn 0.003%, and the balance is Fe. The liquid component used is potassium sodium 1:1 water glass with 46Be at 20°C.

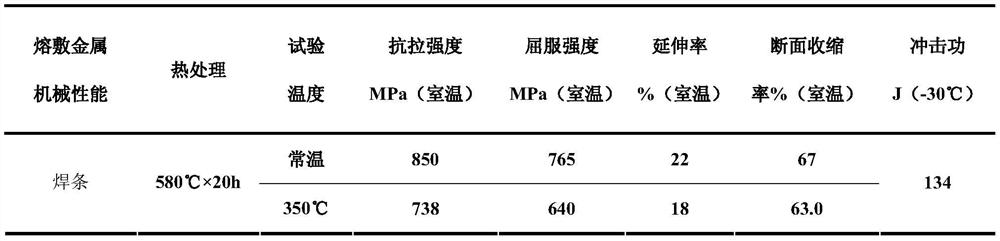

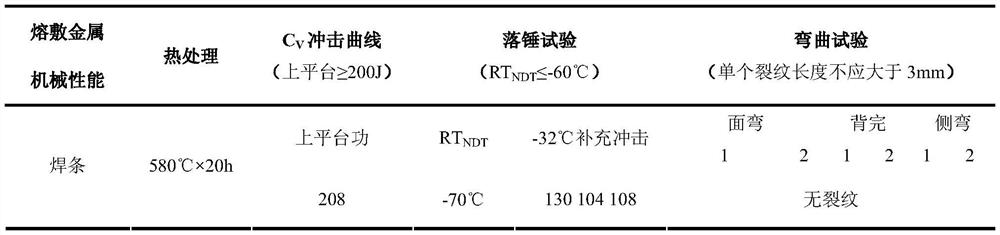

[0019] After mixing the raw materials of the coating above evenly, sieve it with a 40-mesh sieve to 100% below 40 mesh, stir t...

Embodiment 2

[0027] A high-alkalinity and low-hydrogen coating in this embodiment is formed by mixing solid components and liquid components in the coating, and the added weight of the liquid component is 22% of the weight of the solid component; Said solid components include the following components in parts by weight: CaCO 47 parts of CaF 23 parts of TiO 7 parts of NaCO 1 part of CaSiO 4 parts of MgO 3 parts of TiFe 7 parts of SiFe 2 parts of metal Ni powder 5 parts of metal Cr powder 4 parts; Low-alloy steel welding core, the weight percentage of chemical composition measured by chemical analysis method: C 0.13%, Si 0.19%, Mn 1.6%, P0.006%, S0.003%, Cr1.75%, Ni 3.2%, Mo0. 5%, Cu 0.01%, Co 0.001%, B≤0.0005%, Nb≤0.01%, As 0.003%, Sn 0.003%, and the balance is Fe. The liquid component used is potassium sodium 1:1 water glass with 46Be at 20°C

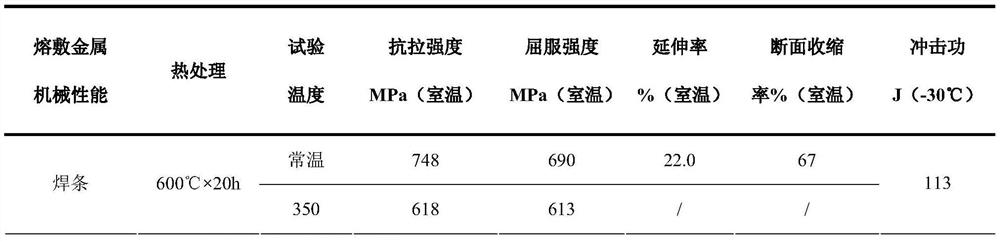

[0028] After mixing the raw materials of the coating above evenly, sieve through a 40-mesh sieve to 100% below 40 mesh, stir the dry powder evenly...

Embodiment 3

[0036] A high-alkalinity and low-hydrogen coating in this embodiment is formed by mixing solid components and liquid components in the coating, and the added weight of the liquid component is 23% of the weight of the solid component; Said solid components include the following components in parts by weight: CaCO 48 parts of CaF 24 parts of TiO 8 parts of NaCO 1 part of CaSiO 5 parts of MgO 2 parts of TiFe 10 parts of SiFe 1 part of metal Ni powder 4 parts of metal Cr powder 3 parts; Low-alloy steel welding core, the weight percentage of chemical composition measured by chemical analysis method: C 0.13%, Si 0.19%, Mn 1.6%, P0.006%, S0.003%, Cr1.75%, Ni 3.2%, Mo0. 5%, Cu 0.01%, Co 0.001%, B≤0.0005%, Nb≤0.01%, As 0.003%, Sn 0.003%, and the balance is Fe. The liquid component used is potassium sodium 1:1 water glass with 46Be at 20°C.

[0037] After mixing the raw materials of the coating above evenly, sieve through a 40-mesh sieve to 100% below 40 mesh, stir the dry powder evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com