Wide-thick steel plate with yield strength of 460Mpa for bridge and method of manufacturing the same

A yield strength, bridge technology, applied in the field of low-alloy wide and thick plate preparation, can solve the problem of high maintenance cost of steel bridges, and achieve the effects of comprehensive performance improvement, weather resistance improvement, and tensile strength stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

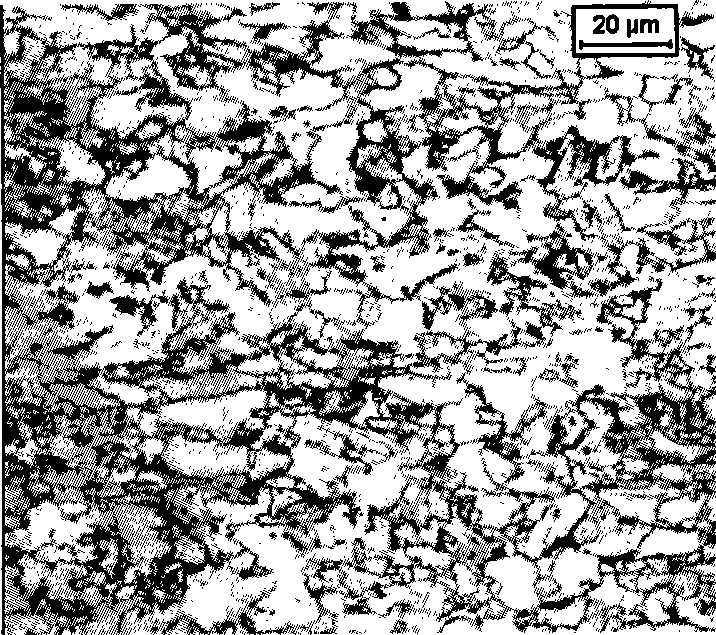

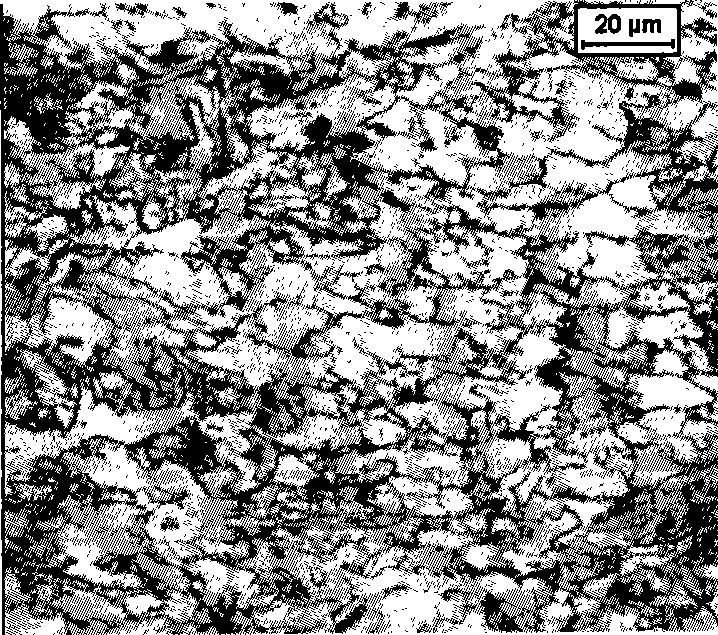

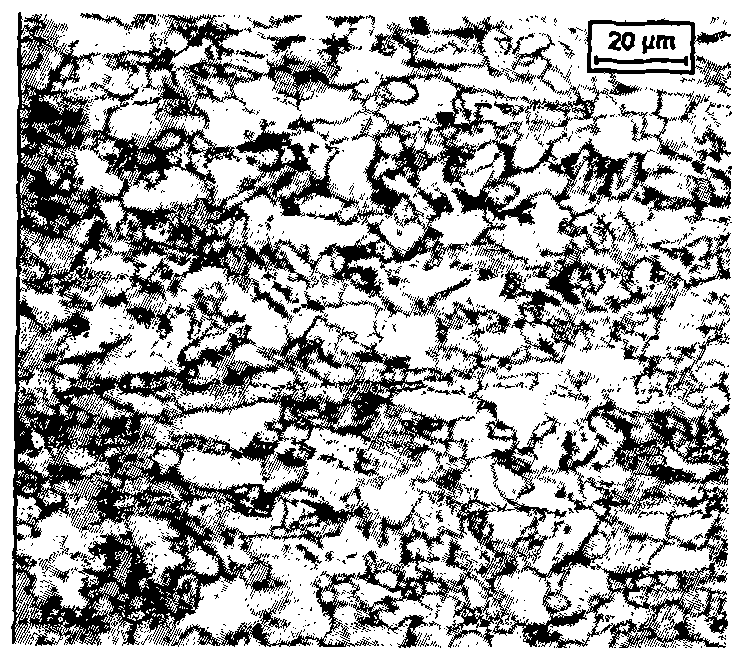

[0013] According to the chemical composition range of the present invention, it is smelted on a laboratory 200kg vacuum smelting furnace, and forged into 110mm×110mm×120mm, and the steel billet is rolled into a 20mm thick steel plate on a laboratory φ450 rolling mill. The chemical compositions of Examples 1 and 2 are shown in Table 1, the controlled rolling and controlled cooling processes of Examples 1 and 2 are shown in Table 2, and the mechanical properties of the steel plates of Examples 1 and 2 are shown in Table 3.

[0014] The chemical composition (mass fraction % of table 1 embodiment 1 and 2, all the other are Fe)

[0015]

[0016] The processing parameter of table 2 embodiment 1 and 2

[0017]

[0018] The product mechanical property of table 3 embodiment 1 and 2

[0019]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com