Multiple electrode gas protection arc welding method

A gas shielded and arc welding technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as porosity resistance degradation, and achieve the effect of excellent weld bead appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

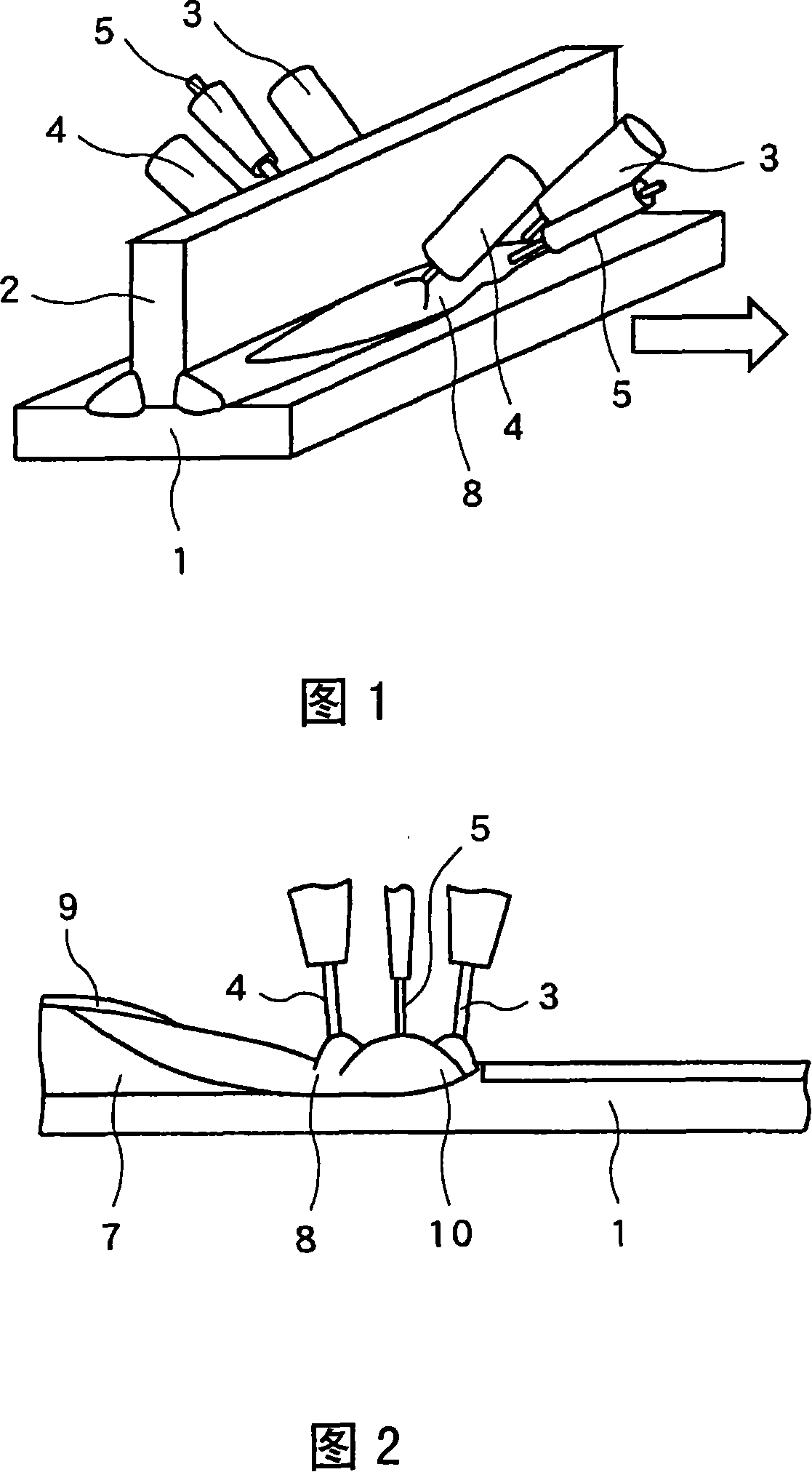

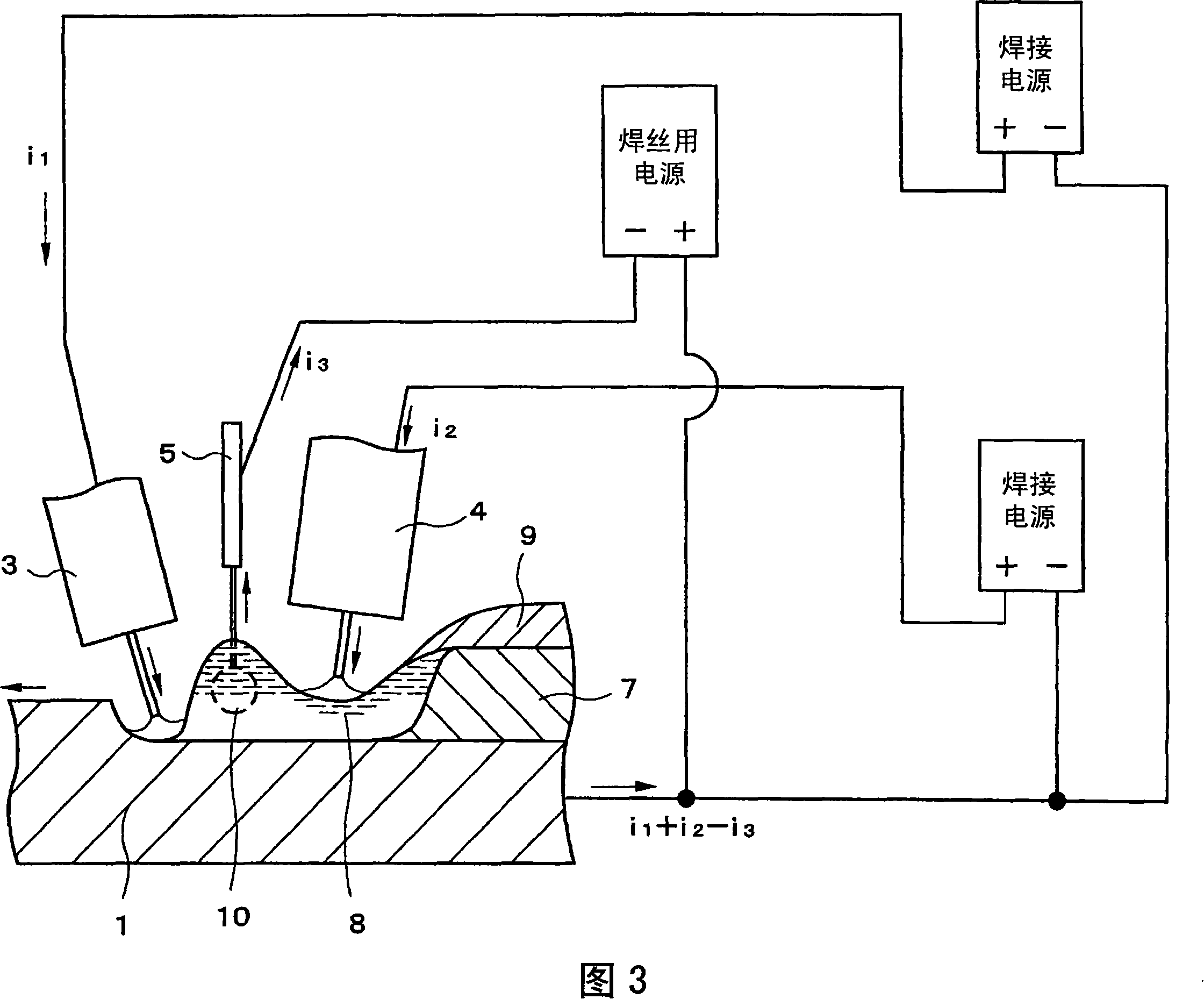

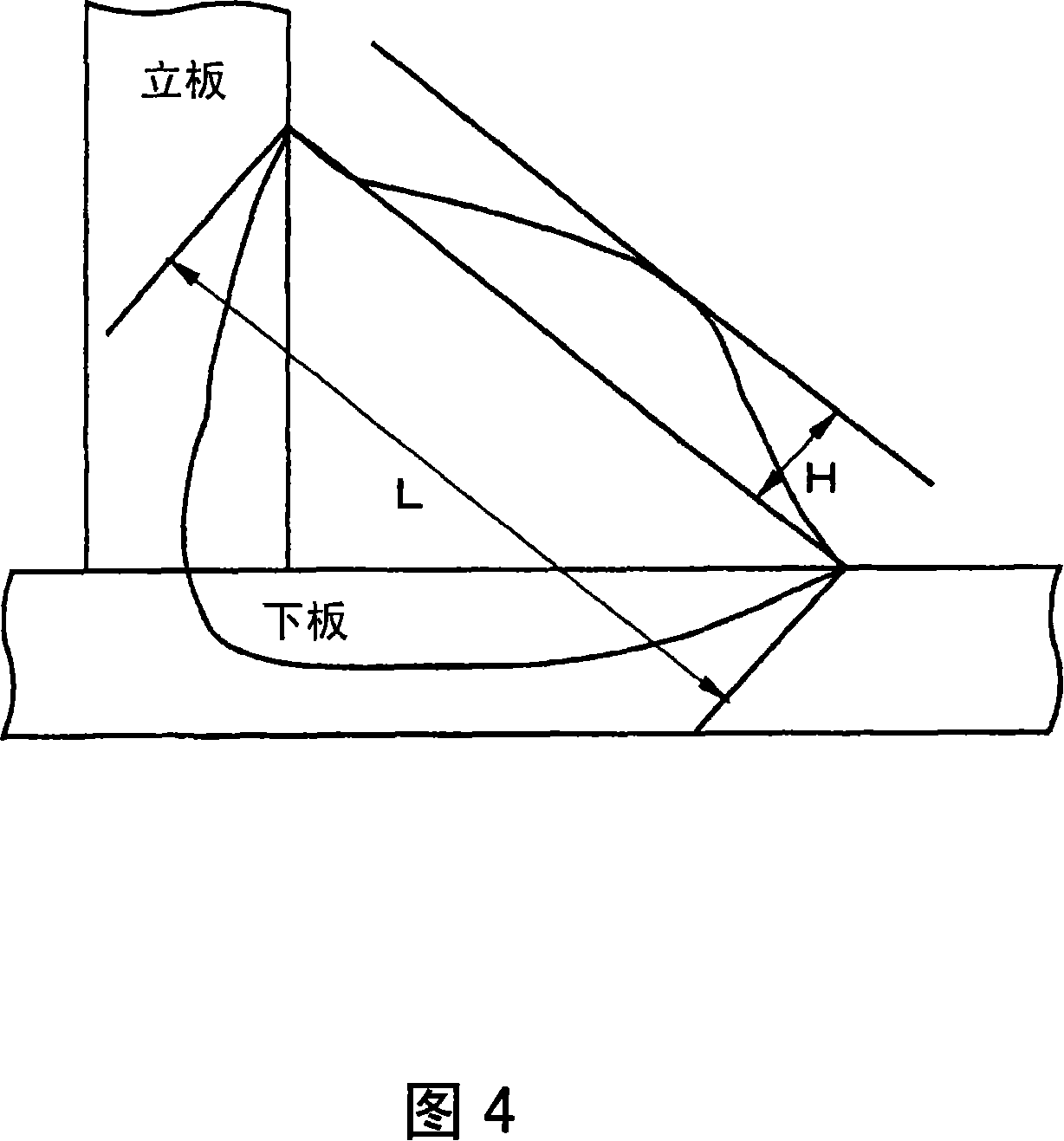

[0016] Embodiments of the present invention will be specifically described below with reference to the drawings. FIG. 1 is a perspective view showing a multi-electrode gas shielded arc welding method according to an embodiment of the present invention, and FIG. 2 is an enlarged longitudinal sectional view showing the same molten metal portion. The welding method shown in FIGS. 1 and 2 relates to horizontal fillet welding, but the present invention is of course not limited to this method. The lower plate 1 as a material to be welded is arranged horizontally, and the vertical plate 2 is vertically arranged on the lower plate 1 . Fillet welding is performed on the corner between the vertical plate 2 and the lower plate 1 through the leading electrode 3 and the trailing electrode 4 . In this case, filler wire 5 is inserted into molten pool 10 between leading electrode 3 and trailing electrode 4 . In this embodiment, the inter-electrode distance between the leading electrode 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com