Robot for underwater welding, robot system and operation method

A robot system and underwater welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of difficult welding seam detection and positioning, many interferences, and difficult matching of feature points, etc., to achieve guaranteed Welding reliability, the effect of accurate welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

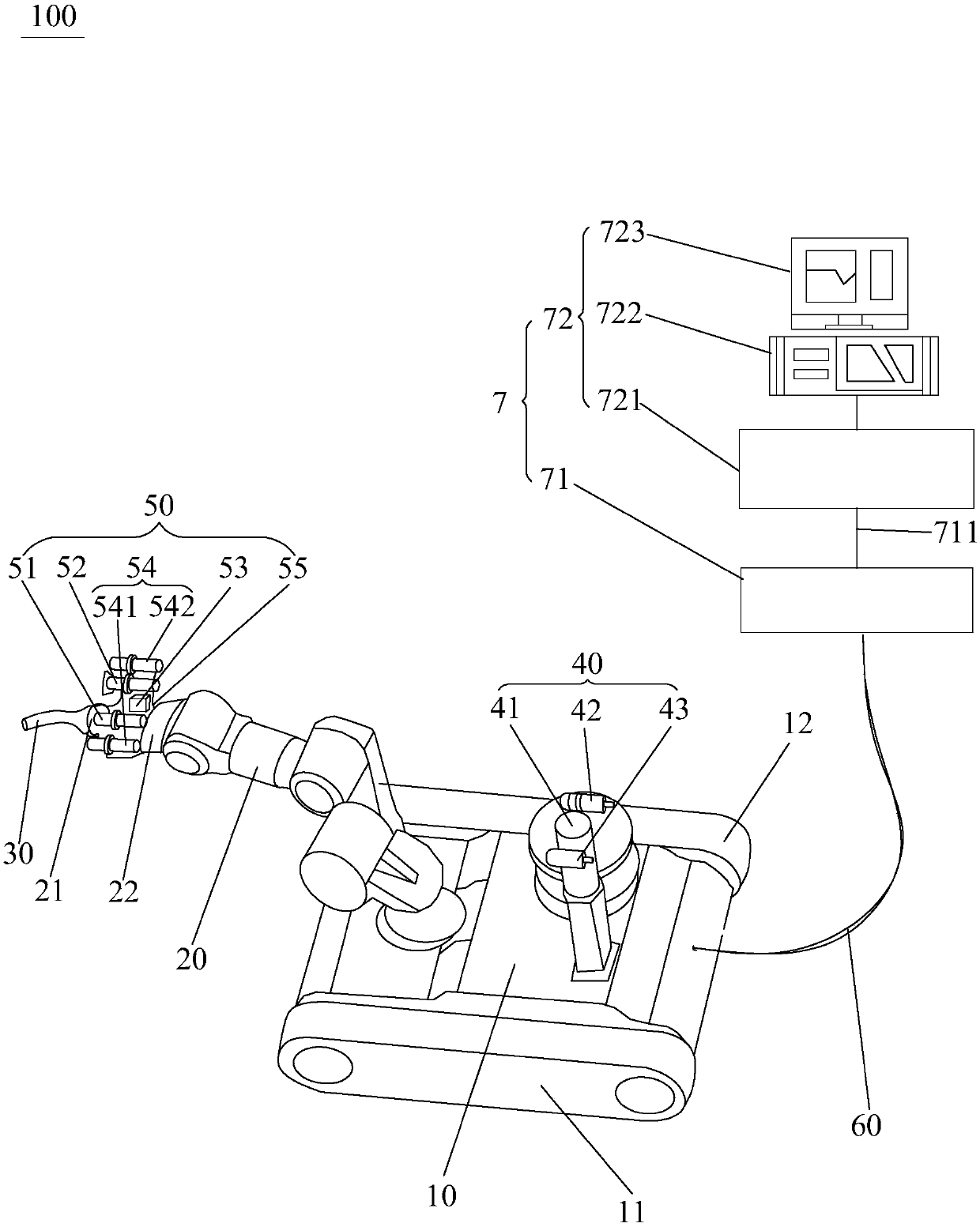

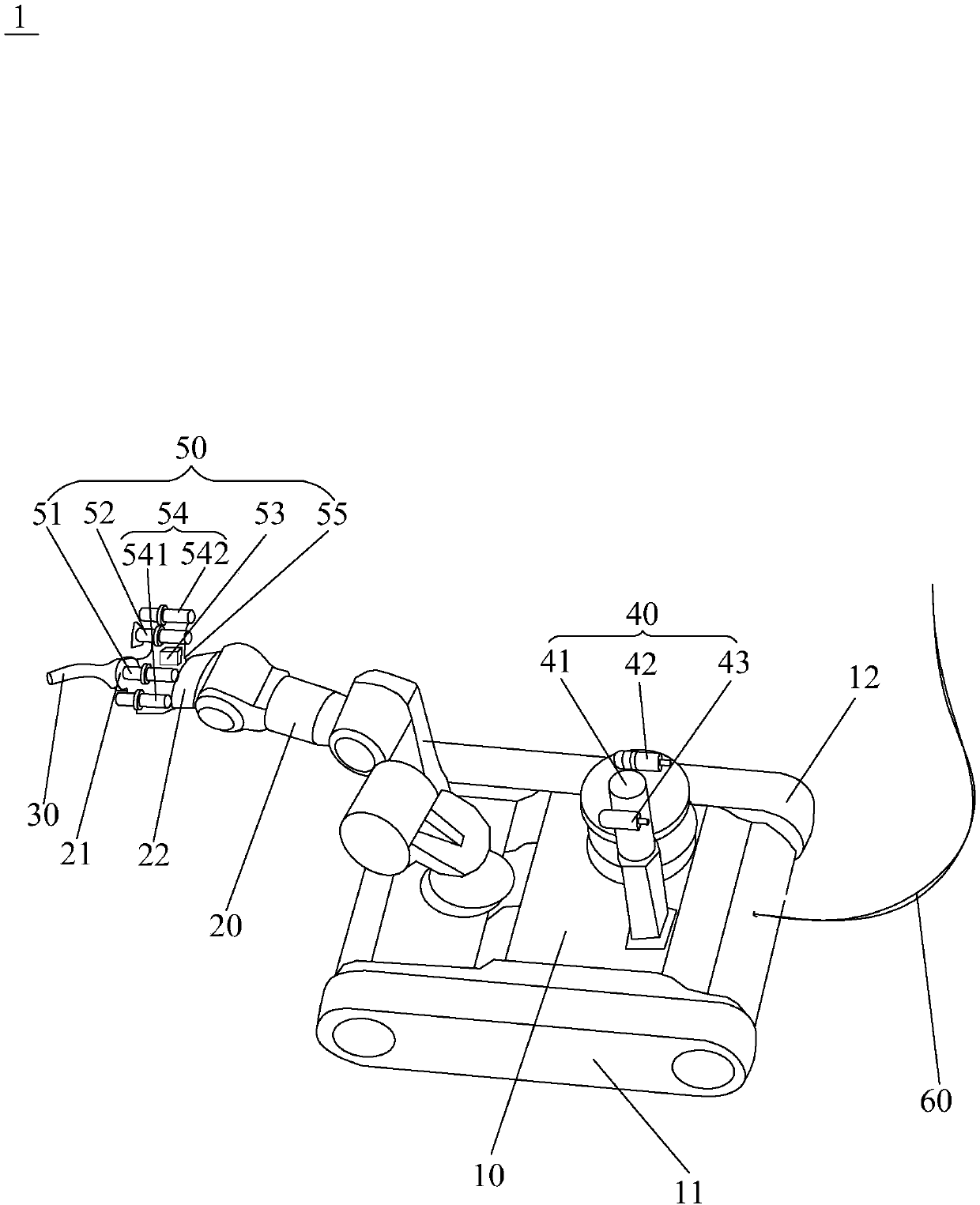

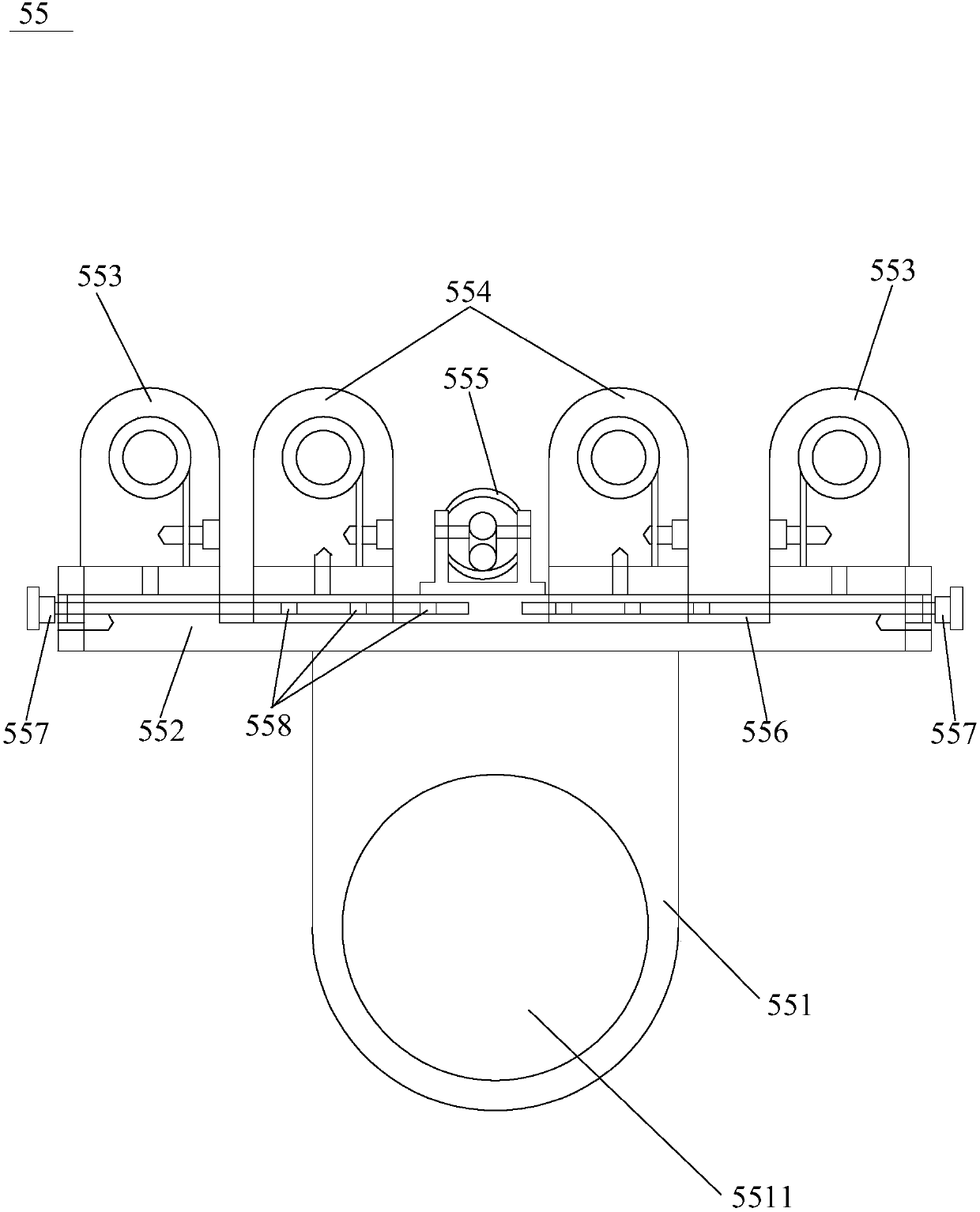

[0043] Please refer to figure 1 , the present invention provides a robot system 100 for underwater welding, including a robot 1 for underwater welding and a control monitoring module 7, the robot 1 for underwater welding can be controlled by the control monitoring module 7 Identify and weld the welding seam, including the mobile carrier 10, the panoramic camera module 40 installed on the mobile carrier 10, the multi-degree-of-freedom mechanical arm 20, the welding torch 30 installed on the end joint 21 of the multi-degree-of-freedom mechanical arm 20, the installation The visual detection module 50 of the adjacent terminal joint 22 of the multi-degree-of-freedom mechanical arm 20 coaxially connected with the terminal joint 21, and the comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com