Ultrasonic-assisted and gas-shielded welding device and method adopting underwater wet method

An ultrasonic-assisted, gas-protected technology, applied in welding equipment, welding accessories, arc welding equipment, etc., to achieve the effects of improving stability, increasing arc ionization, and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] When the welding wire 5 is selected as a solid welding wire, since the solid welding wire does not have the function of producing gas and slag, the gas in the gas storage tank 11 can be selected from the gas required by the GMAW (gasmetalarcwelding, gas metal arc welding) method, i.e. argon, CO 2 , argon+CO 2 , argon+CO 2 +Oxygen, CO 2 + Oxygen, etc., the choice of shielding gas is mainly determined by the material of the metal and the thickness of the welding, for example: aluminum and aluminum alloys generally use argon + 2% CO 2 , stainless steel and high-strength steel use argon + (1-2% oxygen or 5% CO 2 ), carbon steel and low alloy steel use argon + (20-30% CO 2 or 20% oxygen).

Embodiment 2

[0036] When the welding wire 5 is a flux-cored wire, since the flux-cored wire has the functions of gas and slagging (self-protection), the gas introduced can be air or the mixed gas required by the GMAW method.

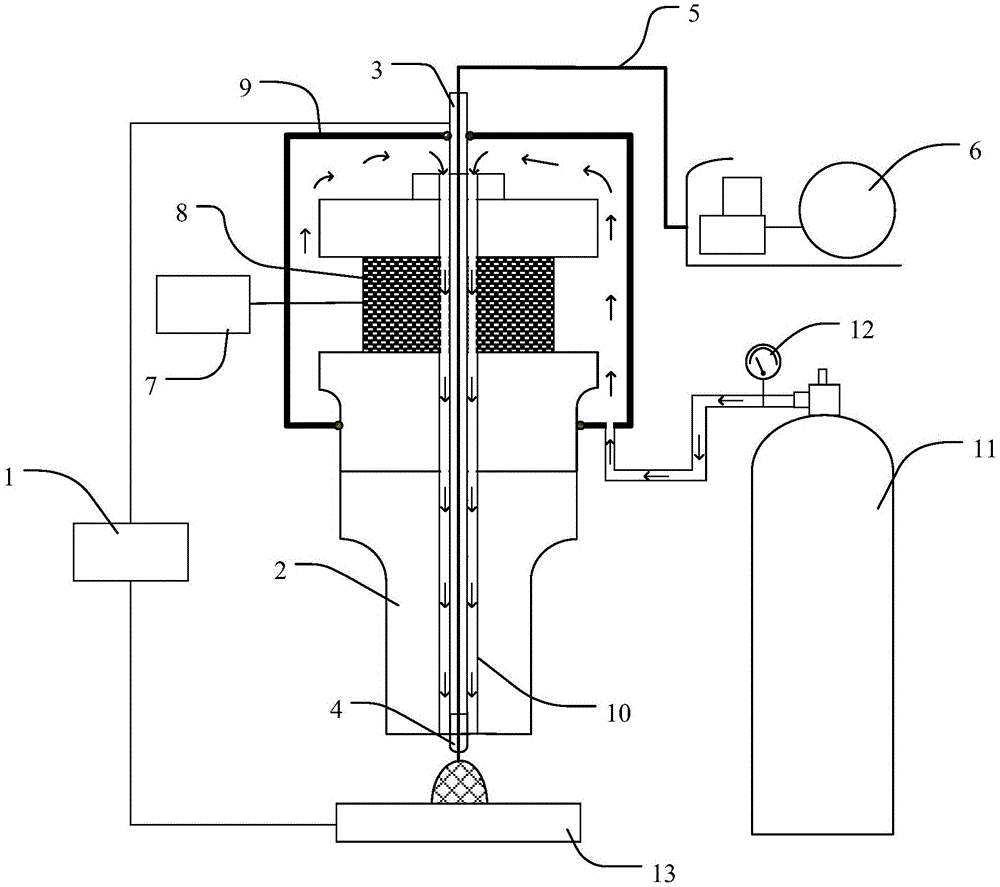

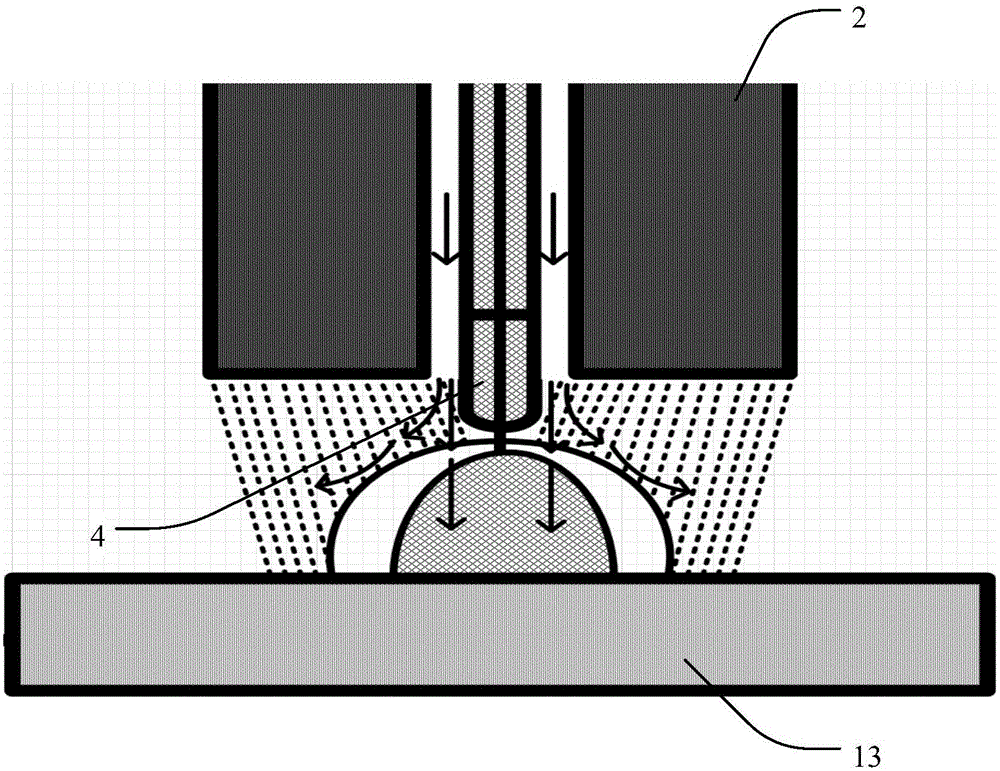

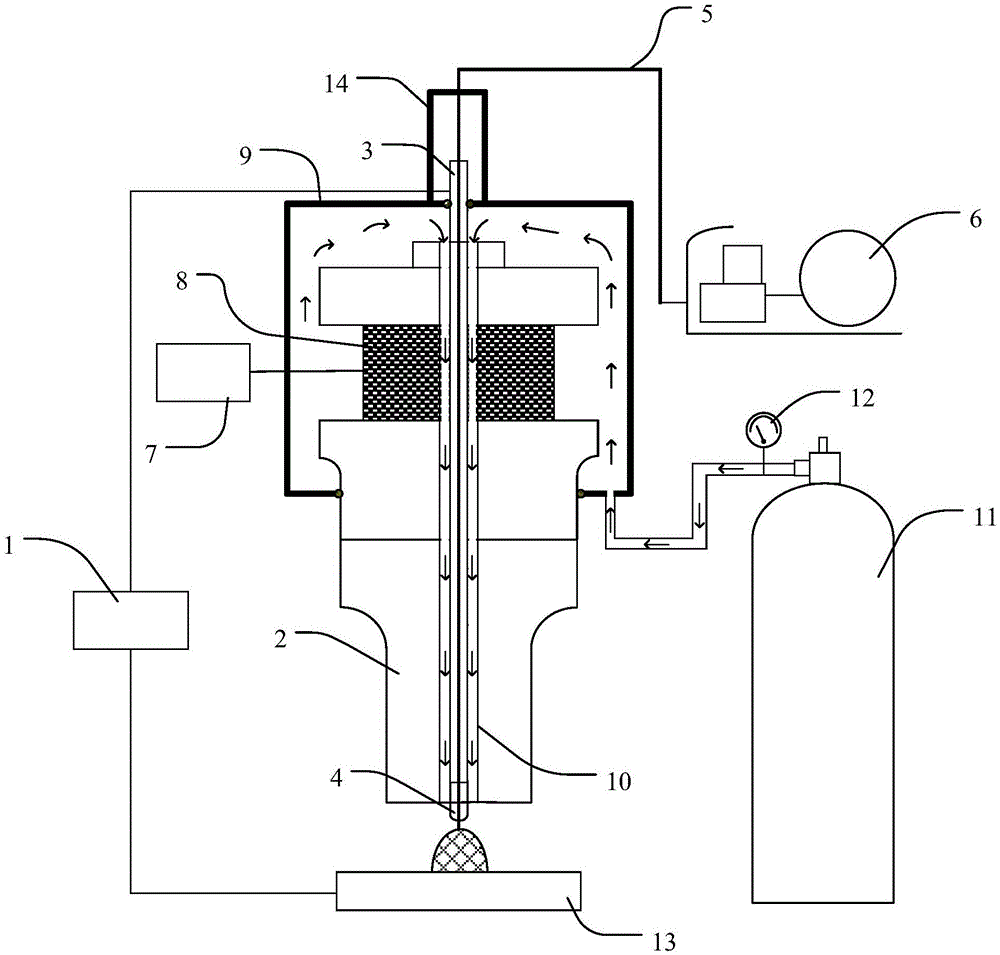

[0037] The invention utilizes the cavitation effect of ultrasound to form an air bag around the arc, and removes the influence of water on the arc, so that the arc can be welded in the air atmosphere, and uses the sound flow effect of ultrasound to make the water around the arc space present a stable beam flow, reduce the impact of external fluctuations on the arc, on this basis, the shielding gas is introduced into the arc area through the insulating sleeve, and the gas medium is provided to the arc space and plays a protective role, including protecting the arc, protecting the welded parts (the welding area as a whole ), avoiding the influence of water, this method transforms ultrasonic-assisted underwater wet welding into ultrasonic melting electrode gas shielded w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com