Underwater welding test chamber

An underwater welding and test chamber technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of the underwater remote control welding system has not yet appeared, the cost of labor input is high, and the test operation is convenient, easy and efficient. The connection and sealing are simple and reliable, and the effect of improving the test simulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

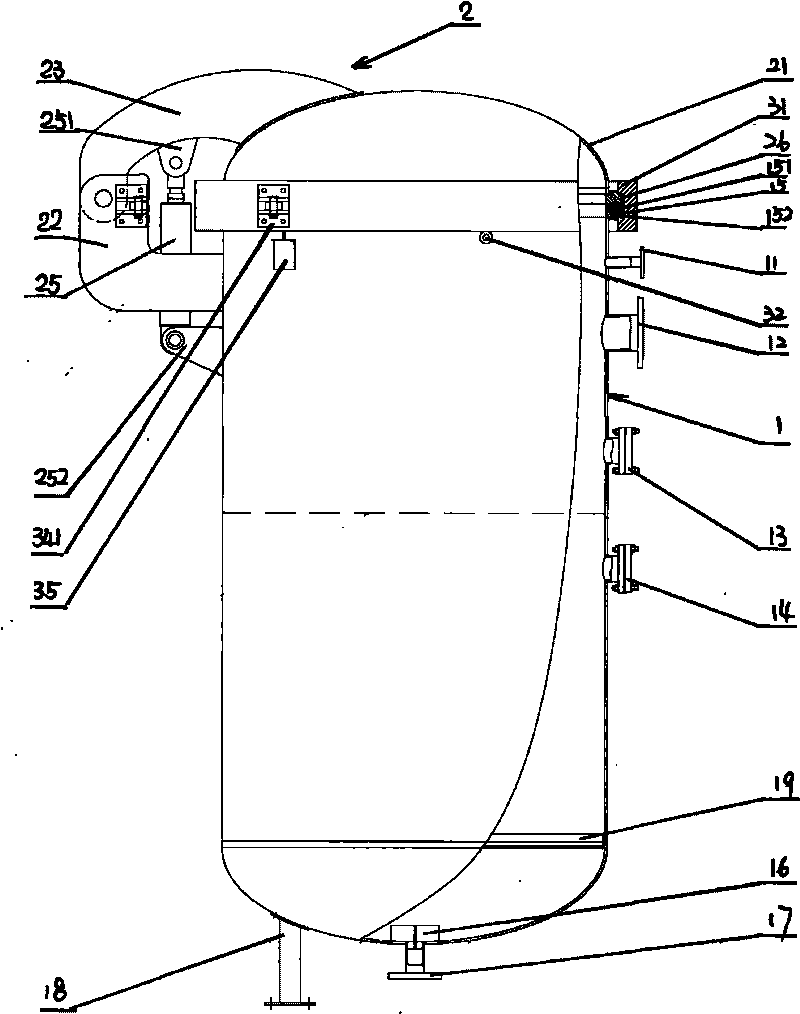

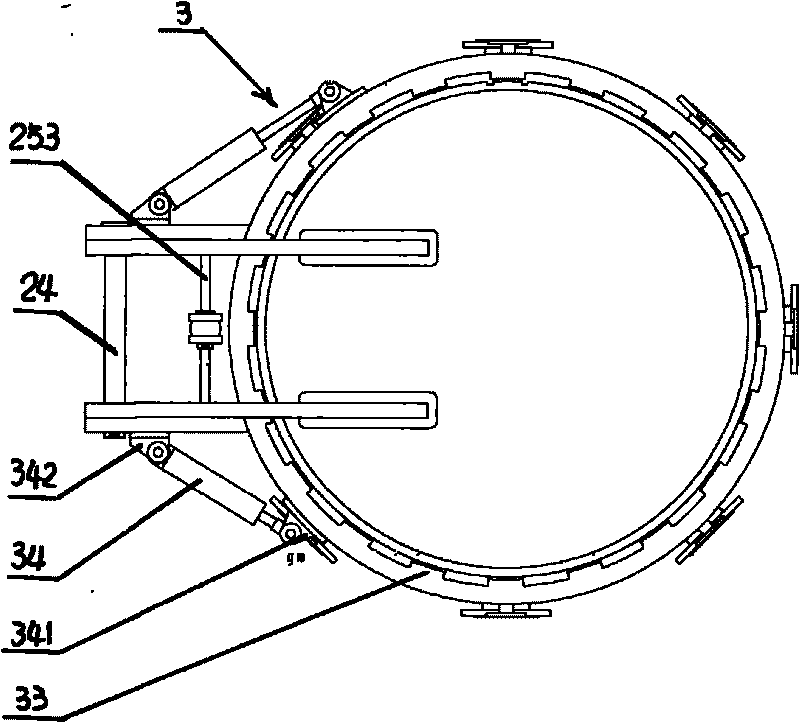

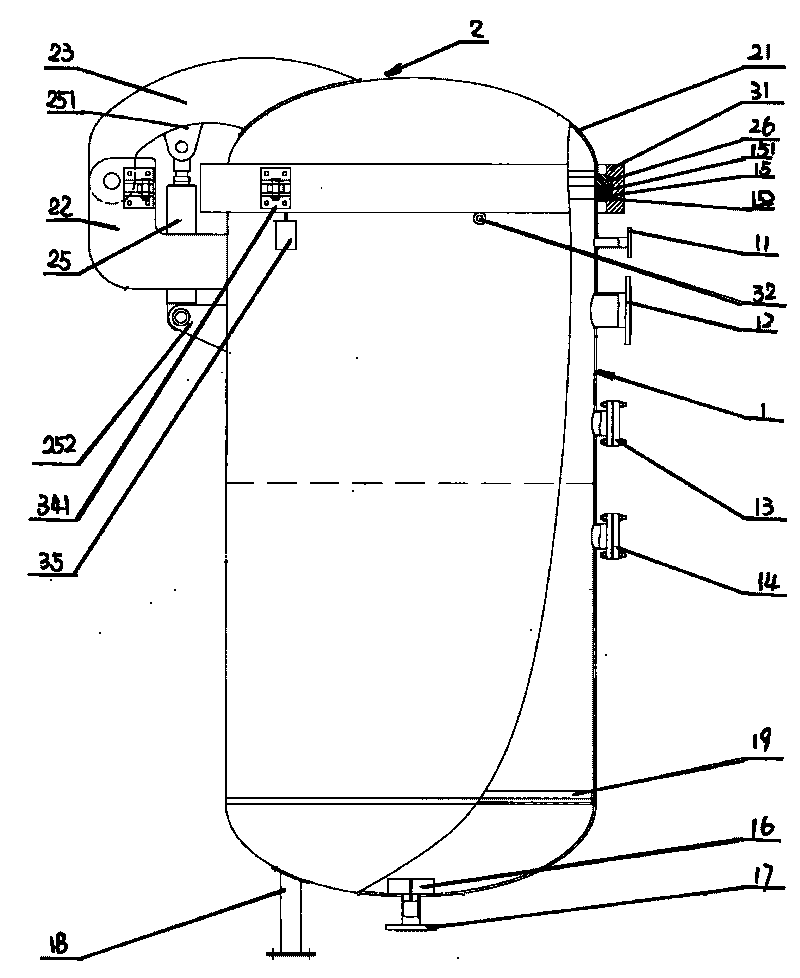

[0016] Depend on figure 1 and figure 2 As shown, an underwater welding test cabin is mainly composed of a cylinder body 1, a quick-opening hatch device 2 and a clamp rotation locking device 3, wherein: a cylinder flange 15 is arranged on the upper edge of the cylinder body 1, and the cylinder body The upper part of the flange 15 is provided with a sealing ring 151, and the lower part is provided with a downwardly opened air hole 152, and a plurality of small-diameter nozzles 11 and large-diameter nozzles 11 are arranged in sequence from the upper edge of the upper cylinder 1 along the circumference of the cylinder 1. Nozzle 12, high-position mirror 13 and low-position mirror 14, the bottom of cylinder body 1 is provided with tray 19, filter screen 16, inlet and outlet nozzle 17 and support 18; quick-opening hatch device 2 drives quick-opening hatch 21 To open and close, the hoop rotates and the locking device 3 drives the hoop 31 to release and lock the hoop through the snap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com