Simulation control system for testing environmental parameters of salt expansion tester

A technology of salt expansion tester and test environment, applied in control/regulation system, non-electric variable control, simultaneous control of multiple variables, etc., can solve the problems of low integration, simple function, small test results, etc. The effect of improving the test accuracy and improving the test simulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

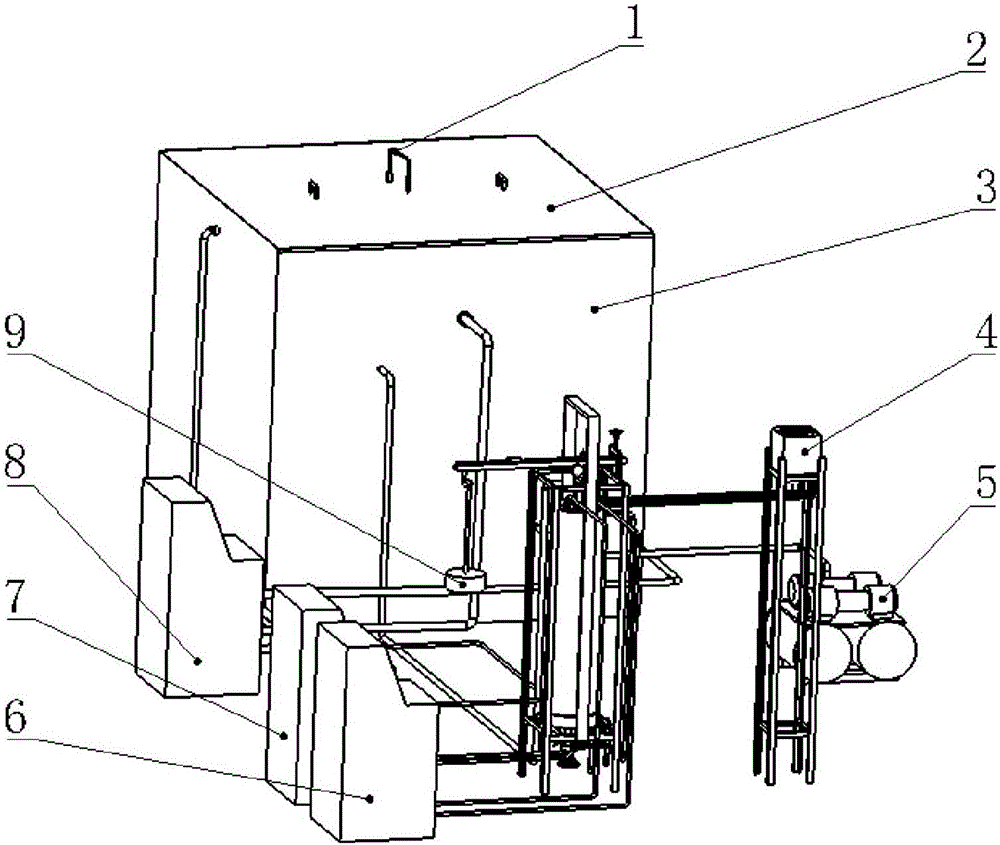

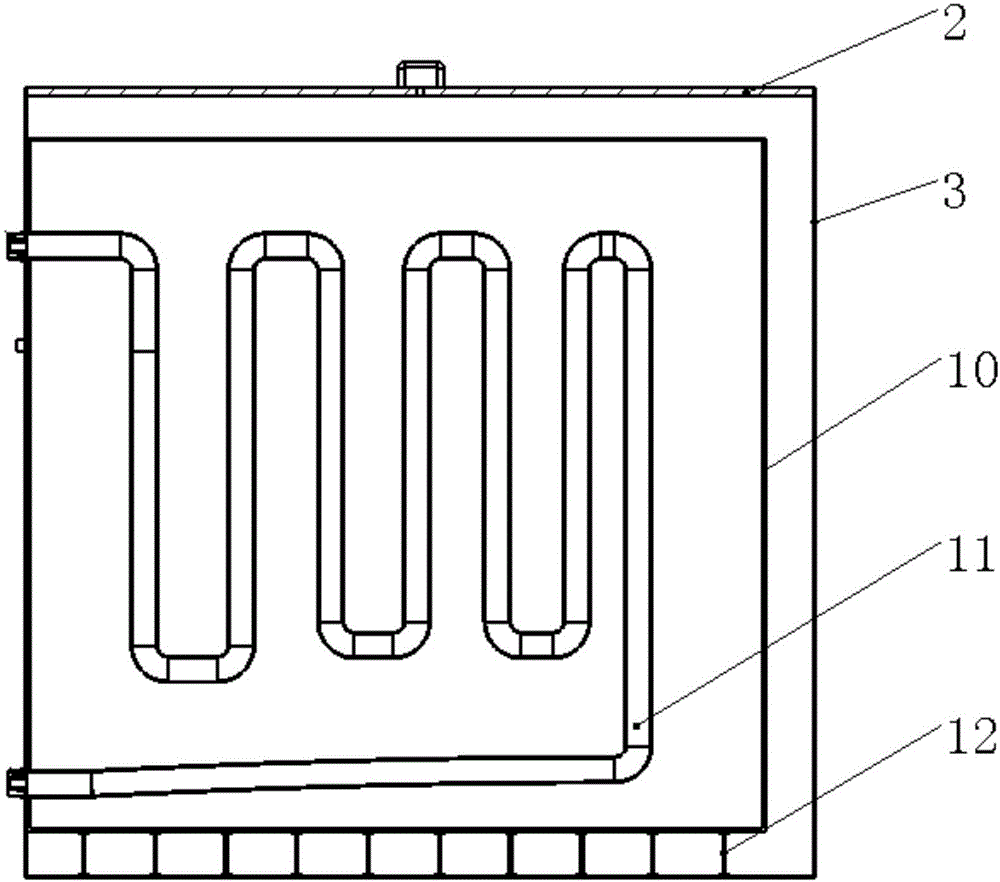

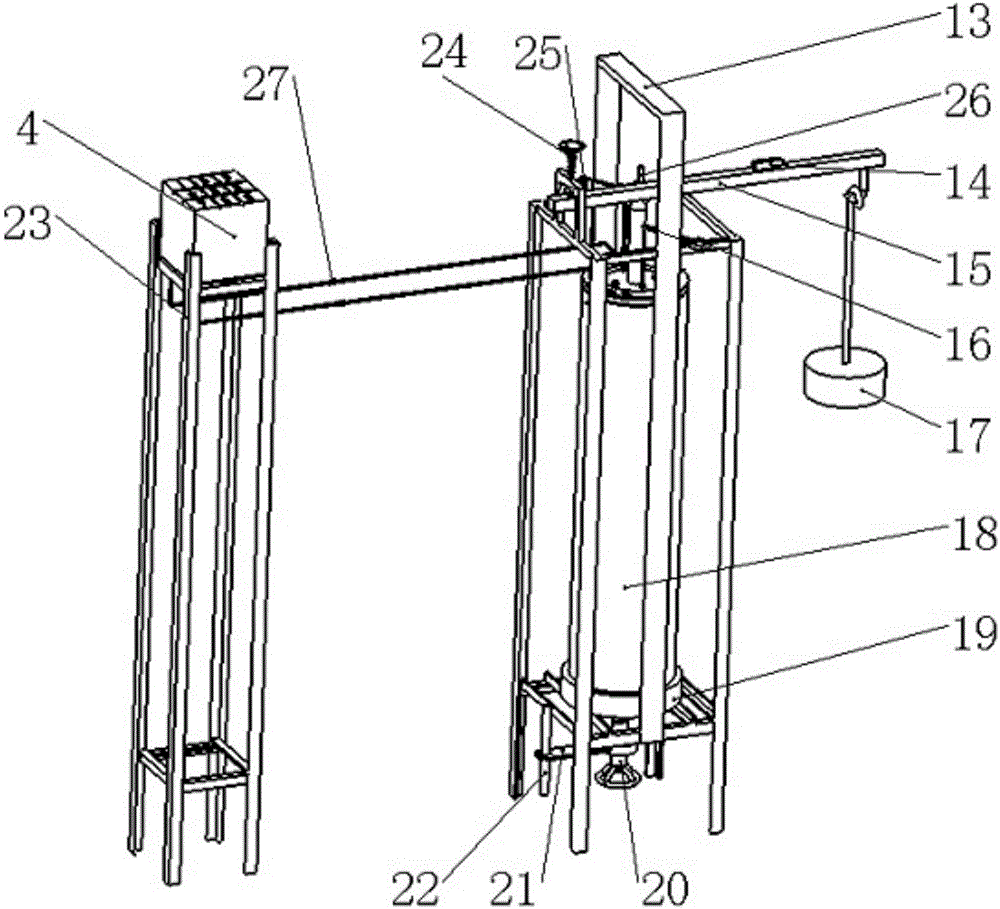

[0041] The optimal implementation mode: if Figure 1-11 As shown, a kind of salt expansion tester comprises sample barrel and temperature control system, and sample barrel includes outer barrel 18 and the inner cylinder that is arranged in the outer barrel, and outer barrel 18 is vertically installed on the sample barrel frame 13, and the temperature The control system includes a circulating fluid temperature control device A6, which circulates through the circulating fluid pipeline and the circumferential circulating fluid chamber formed by the gap between the outer barrel and the inner barrel. Sample dry humidity control system for sample dry humidity control.

[0042] In this way, when the salt swelling tester is used, it can realize more environmental parameter simulations, and can realize the control of the dry humidity of the sample, and then realize the dry-wet cycle salt swelling test with continuous change of water content at a constant temperature, and help to realiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com