Local dry-type welding small-sized drainage device

A drainage device, dry technology, applied in auxiliary devices, welding accessories, welding equipment, etc., can solve the problems of inability to monitor, complex and large equipment, and achieve the effects of light operation, long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

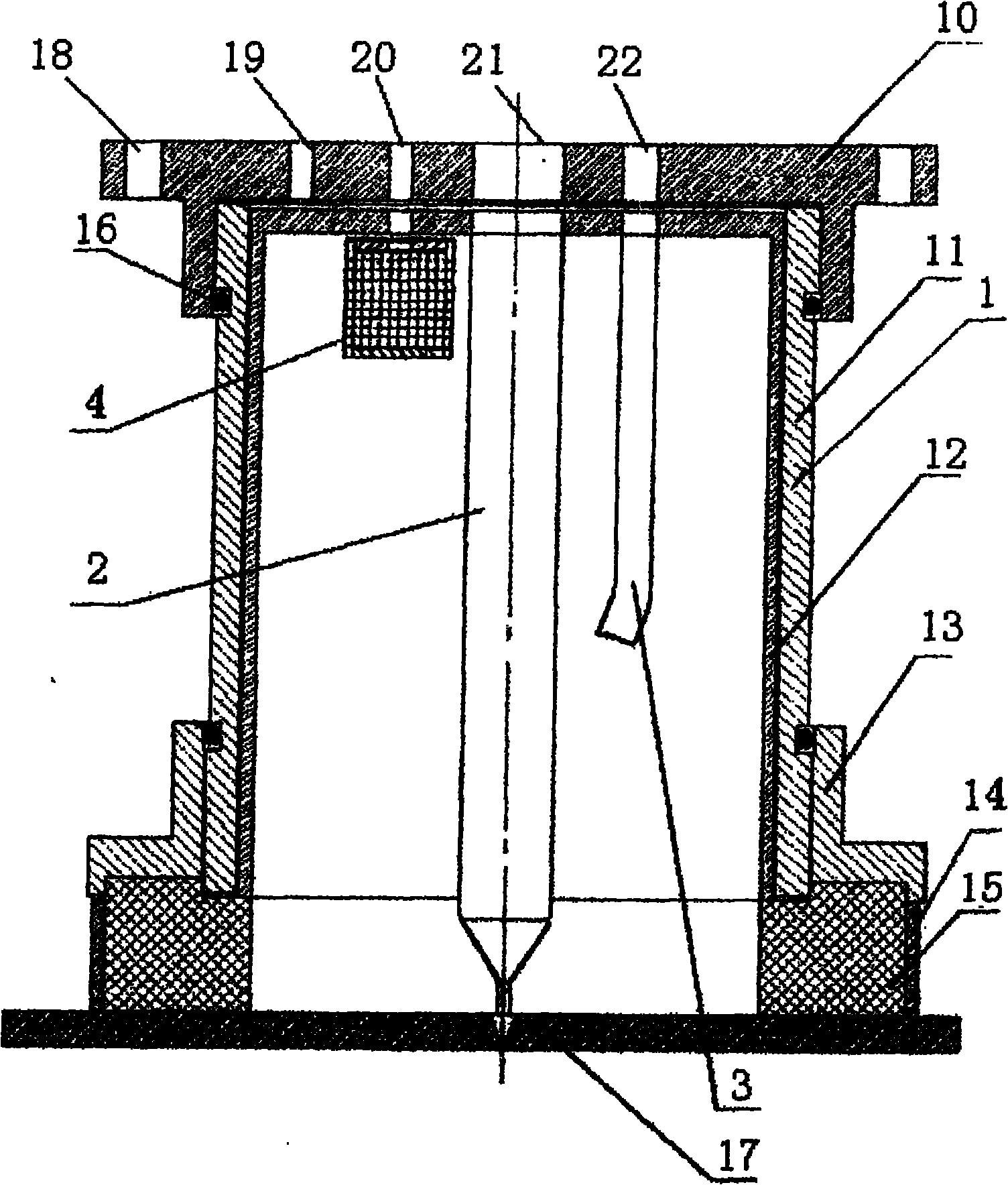

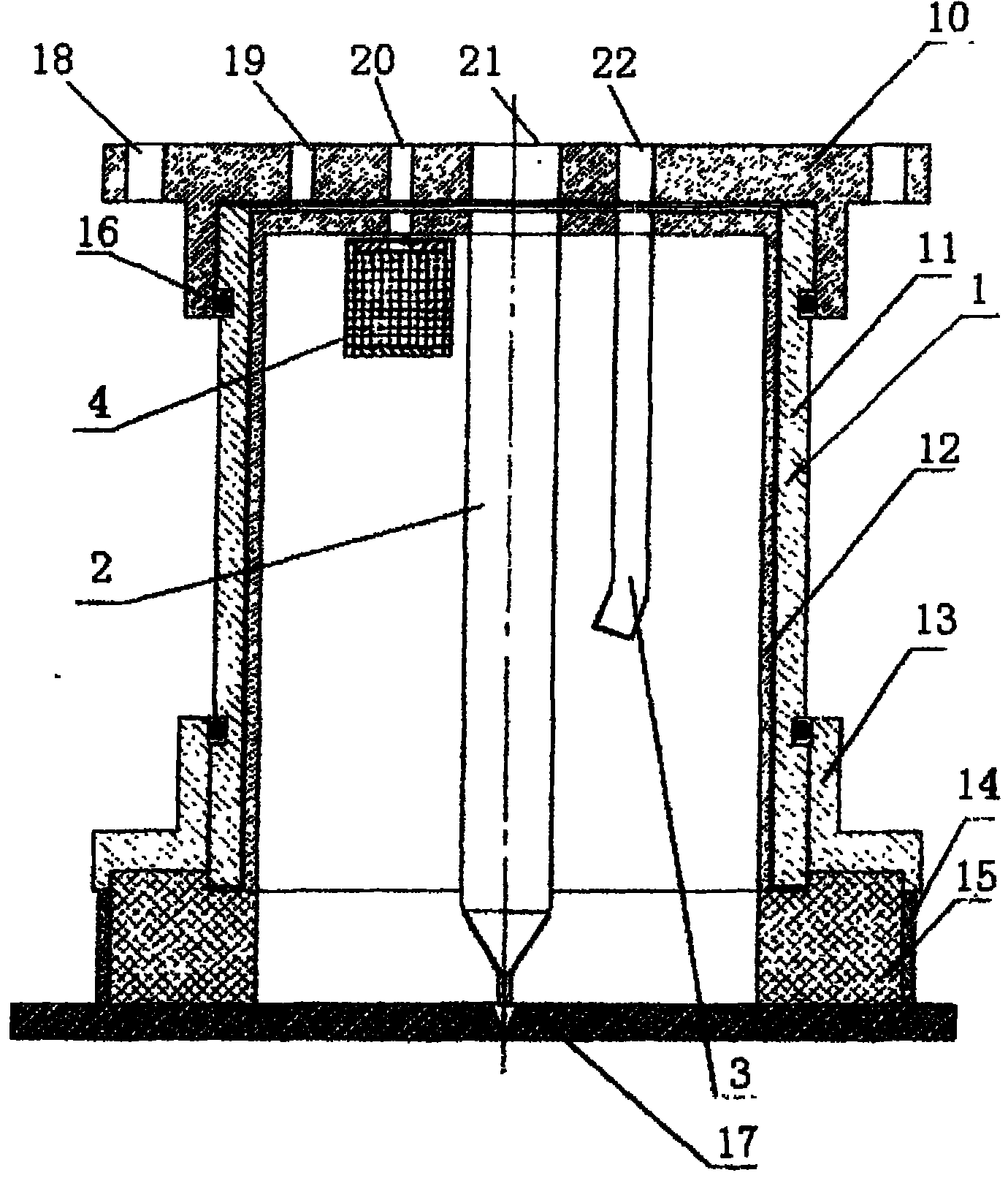

[0014] Depend on figure 1 As shown, a local dry welding small drainage device is mainly composed of a drainage cover 1, a small welding torch 2 and a miniature underwater welding optical fiber viewing mirror 3, wherein: the drainage cover 1 is mainly composed of an upper end cover 10, a locking sleeve 11 , water seepage sleeve 12, lower end cover 13, sealing sleeve 14 and drainage sponge 15, the upper and lower ends of locking sleeve 11 are screwed with upper end cover 10 and lower end cover 13 respectively and sealing ring 16 is installed, embedded in the inner cavity of locking sleeve 11 A water seepage cover 12, the water seepage cover 12 is connected with the upper end cover 10, and the drainage sponge 15 is embedded under the lower end cover 13, the locking sleeve 11 and the water seepage cover 12, and the drainage sponge 15 is bonded together. A layer of sealing sleeve 14 is placed around it, and the cover body 1 and the workpiece 17 to be welded form a closed space unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com