Partial dry type automatic welding drainage arrangement

An automatic welding and drainage device technology, applied in welding equipment, auxiliary equipment, welding equipment, etc., can solve the problems of low flexibility, short life of key components, and inability to use automatic welding, etc., to simplify design, improve welding quality, and improve The effect of welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

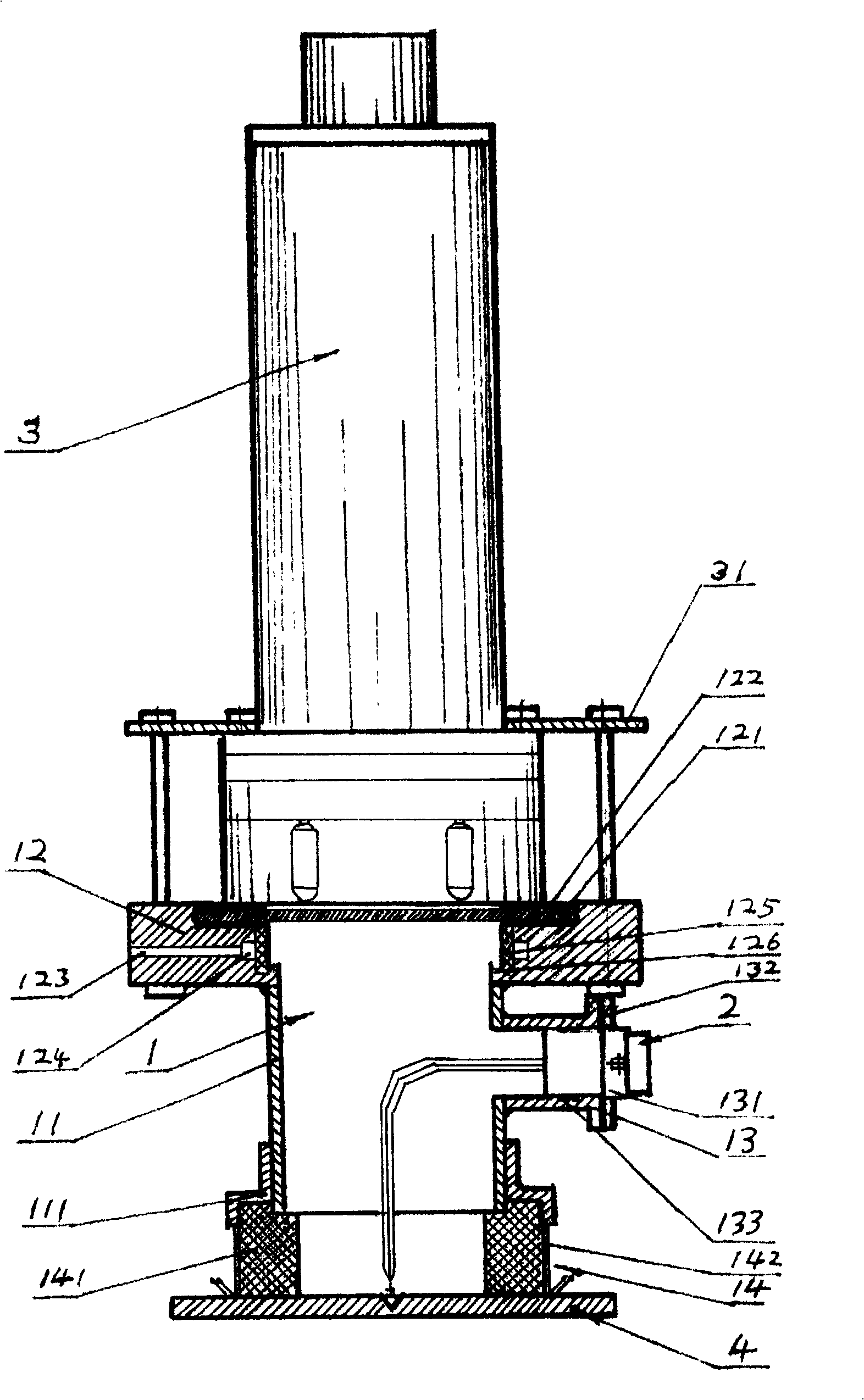

[0015] Depend on figure 1 As shown, a partial dry automatic welding drainage device is mainly composed of a drainage cover 1, a flexible welding torch 2 and an underwater welding camera 3, wherein: a cylindrical cylinder 11, a camera connection end cover 12, and a welding torch insertion port 13 Form the drainage cover 1 with the sealing body 14, the end of the camera head connecting end cap 12 is provided with a lens 121 and a sealing ring 122, wherein an air intake hole 123 and a buffer air chamber 124 are formed, and in the through hole connecting the end cap 12 An annular metal screen 125 and a spring washer 126 are set, a welding torch insertion port 13 is connected to one side of the cylinder body 11, a sealing ring 132 is arranged at the port, an O-shaped sealing ring 133 is arranged inside, a welding torch snap ring 131 and a welding torch insertion port 13 Screw connection, the lower part of the cylinder body 11 is screwed to the threaded flange 111, the threaded flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com