Friction stitch welding experimental device

A technology of friction stitch welding and experimental equipment, which is applied in the direction of auxiliary equipment, welding equipment, welding equipment, etc., can solve problems such as the inability to complete the repair of cracks on submarine pipelines, and achieves a simple structure, excellent welding quality, and high welding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

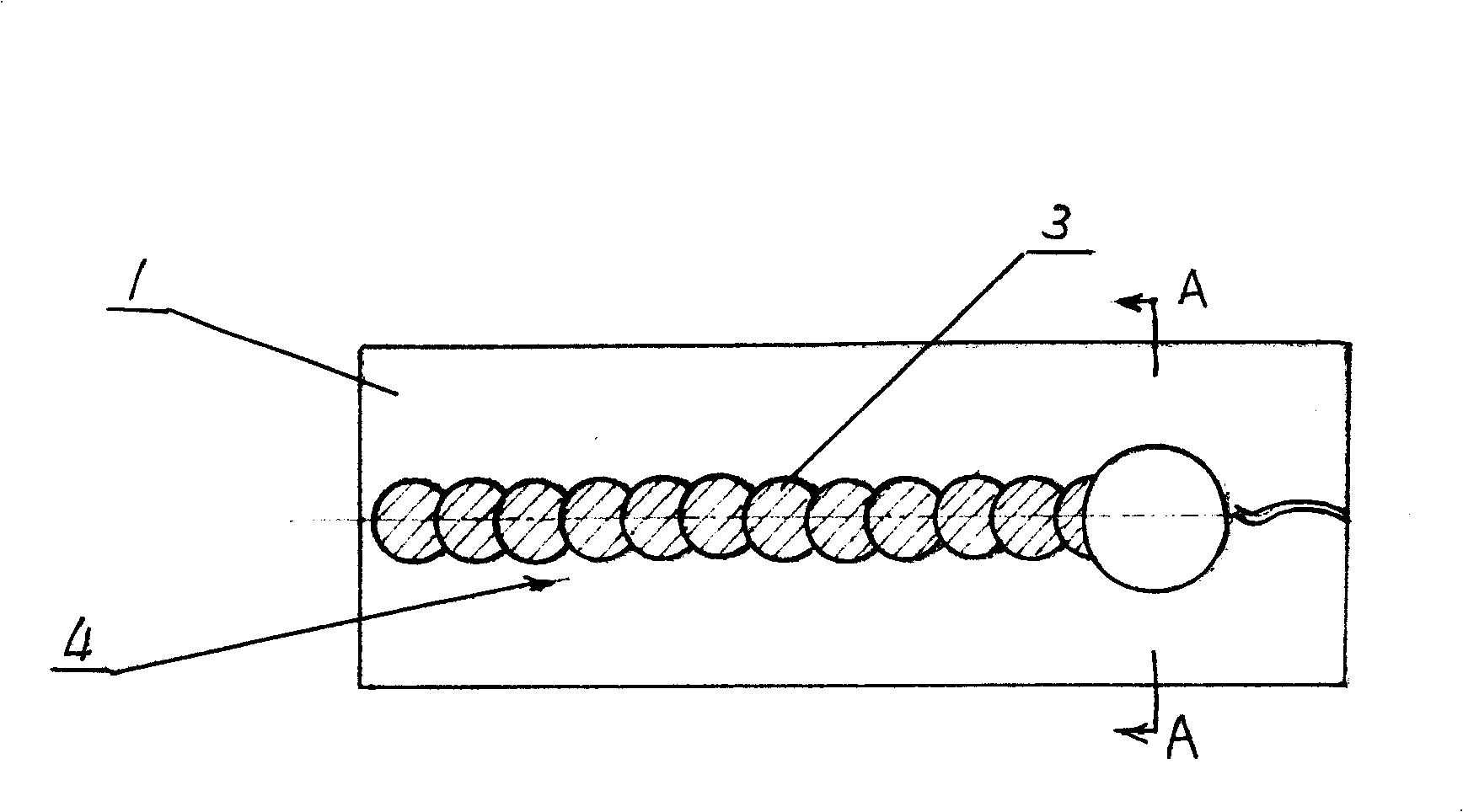

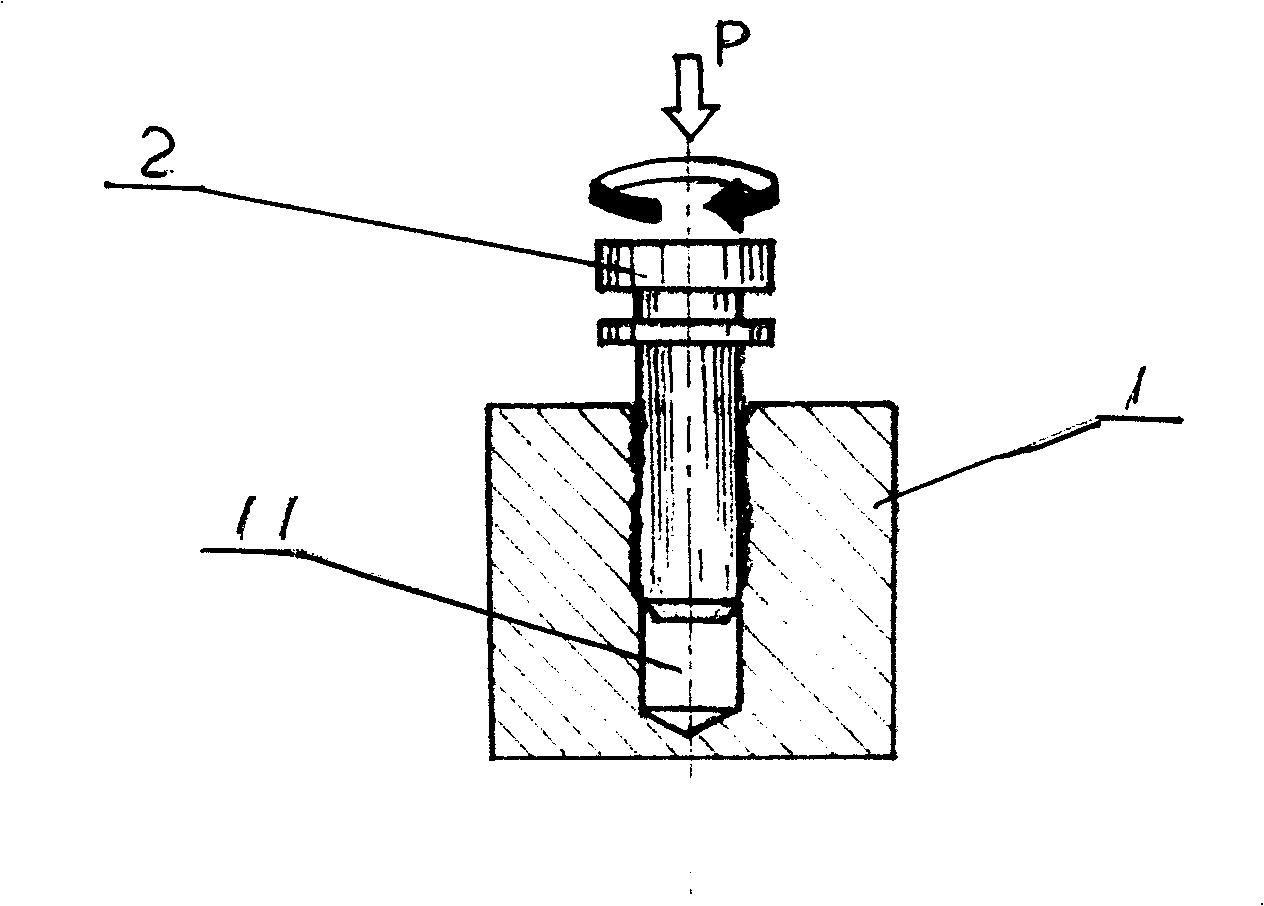

[0018] Depend on Figure 1A , Figure 1B , Figure 2A and Figure 2B Shown, a kind of friction stitch welding method, this method comprises the following steps: on the object to be welded 1, drill welding hole 11, use the stopper rod 2 that diameter is slightly smaller than welding hole 11 to rotate at high speed in welding hole 11, and axially apply The pressure P causes the contact surface between the stopper rod 2 and the welding hole 11 to be heated and melted, and undergoes a crystallization and metallurgical reaction to form a welding unit 3 , completing a series of overlapping welding units 3 to form a complete lap welding seam 4 .

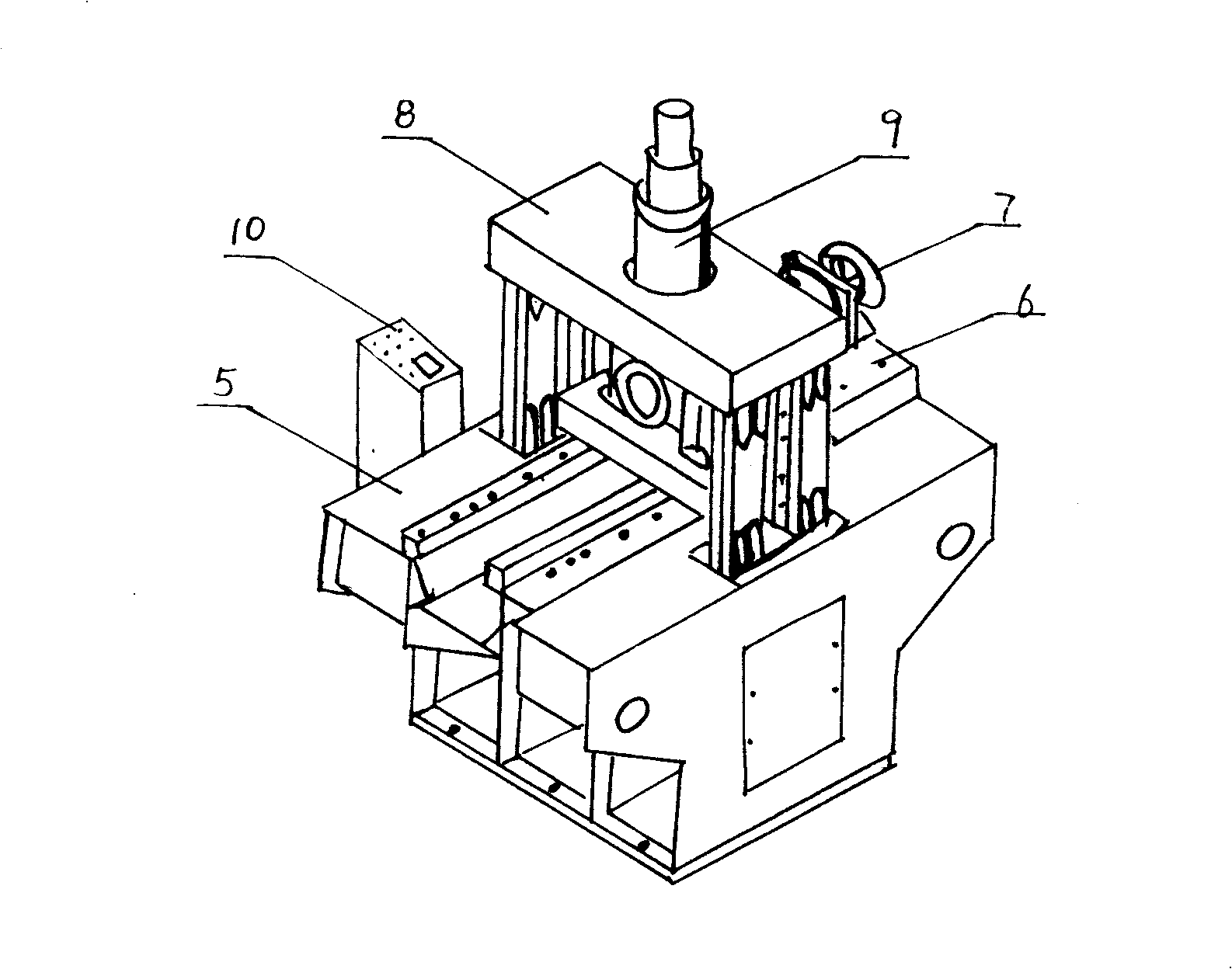

[0019] The experimental device used to realize the friction stitch welding method is mainly composed of a base 5, a mobile slide table 6, a workpiece fixture 7, a beam 8, a friction spindle head 9 and a console 10, and is characterized in that: the base 5 is screwed with a beam 8. A friction spindle head 9 is also arranged on it, and a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com