Underwater welding local mask with welding line tracking function

A technology for underwater welding and tracking functions, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of complex processing of parts, inconvenient installation of sensors on the surface of partial covers, and independent size, etc., and achieve the effect of easy replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the drawings and embodiments.

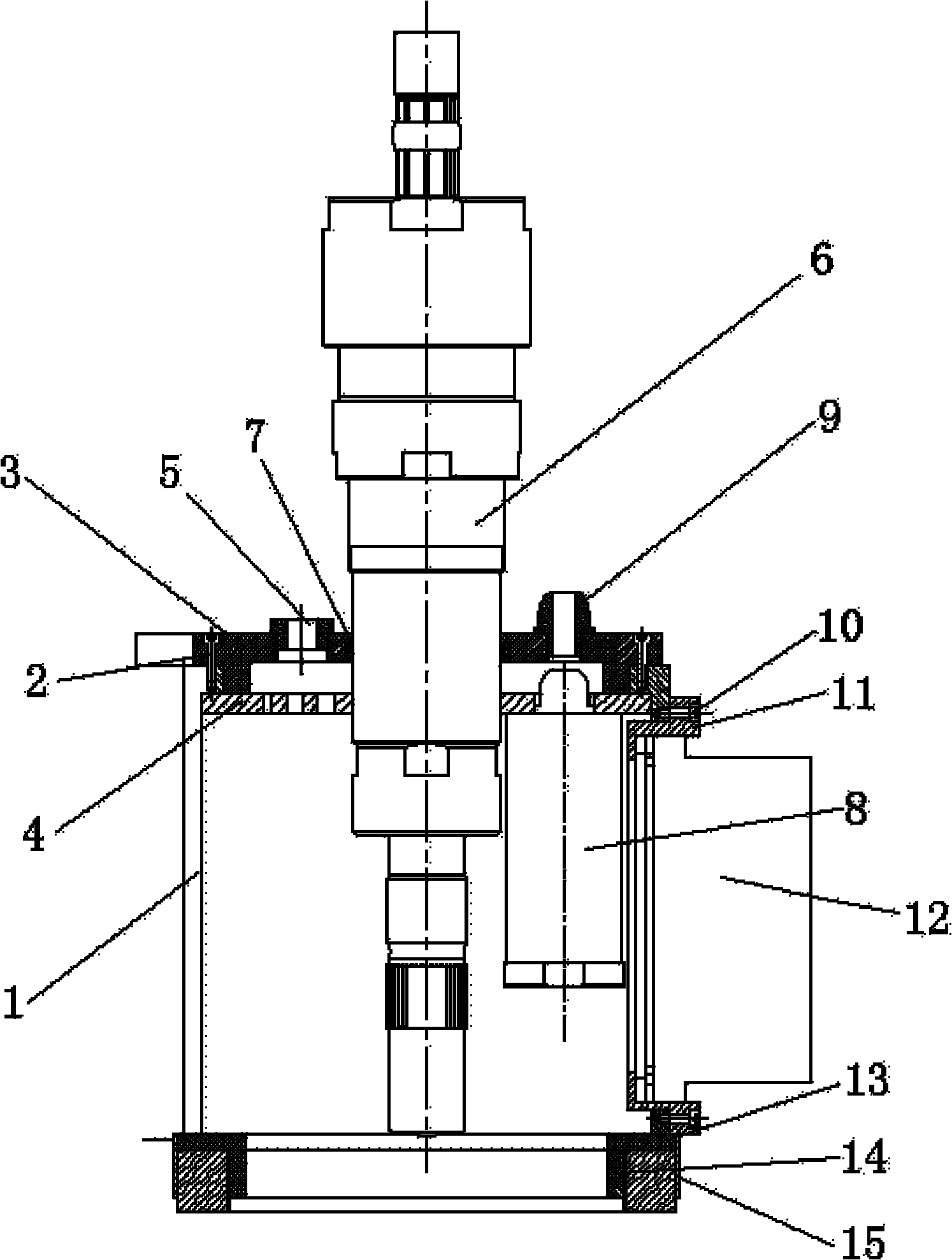

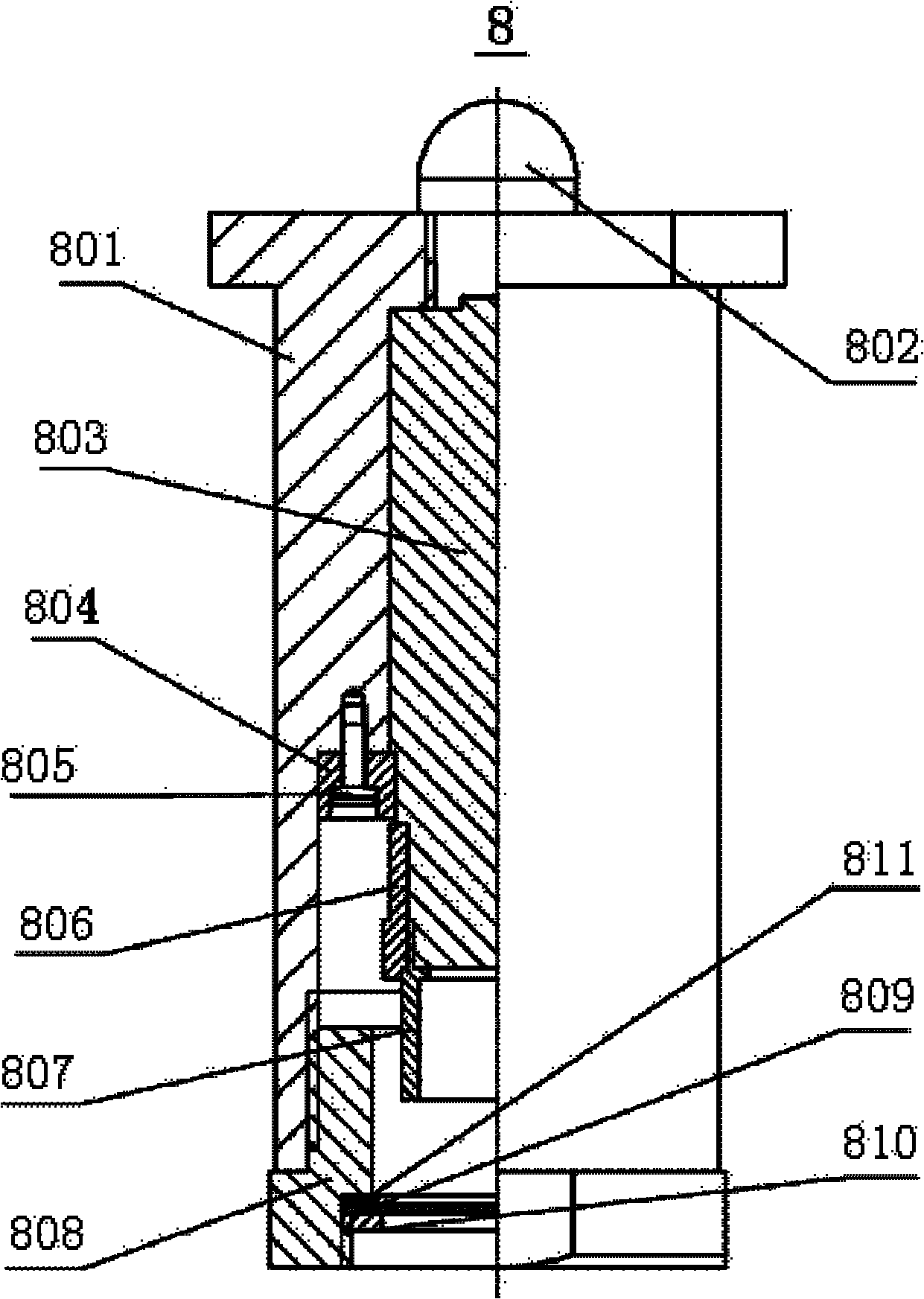

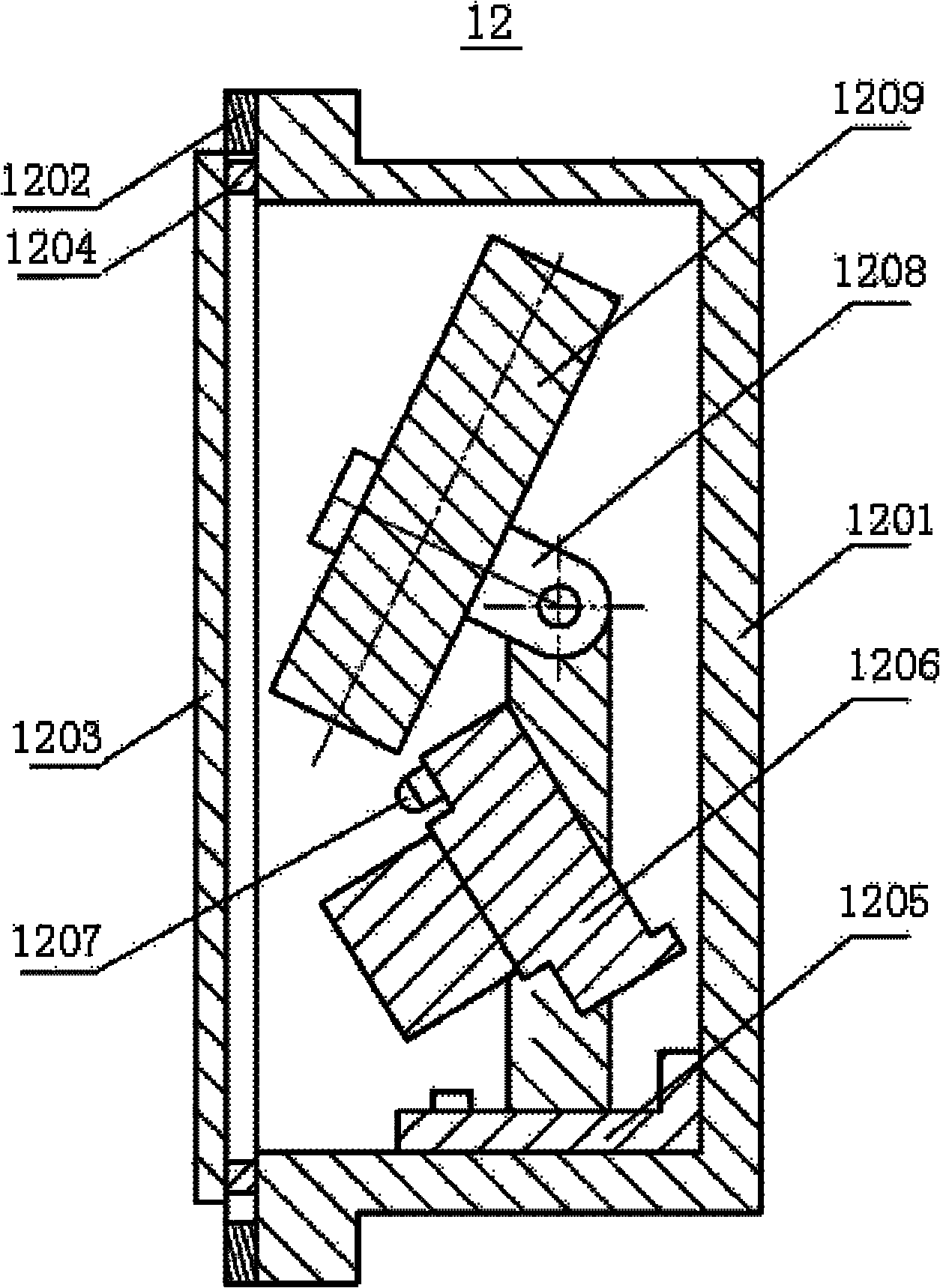

[0019] Such as figure 1 As shown, the present invention includes a cover body 1, the top of the cover body 1 is provided with a cover cover 3 through a connecting screw 2, a spoiler 4 is provided under the cover 3, and a number of through holes are arranged on the spoiler 4 at intervals. An air chamber is formed between the plate 4 and the cover 3, and a layer of porous material (not shown in the figure) is arranged above the spoiler 4 in the air chamber, so that the air in the air chamber can flow evenly through the spoiler at a lower speed 4 through holes. The cover 3 is provided with a drain gas connector 5 for introducing gas into the gas chamber. The welding torch 6 penetrates into the cover 1 from the middle of the cover 3 and the spoiler 4, and a sealing member 7 is provided at the joint between the welding torch 6 and the cover 3. A tracking camera assembly 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com