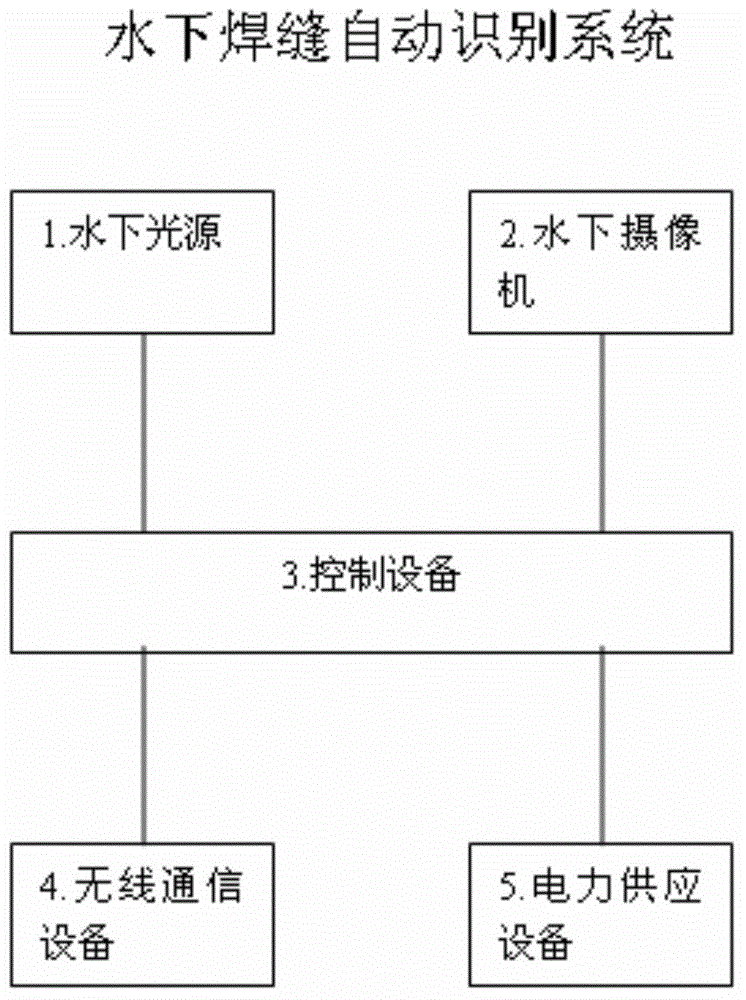

Underwater welding seam automatic identification system

An automatic identification system and identification system technology, applied in the field of underwater weld automatic identification system, can solve the problems of blurred workpiece image, large amount of data, and less effective data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

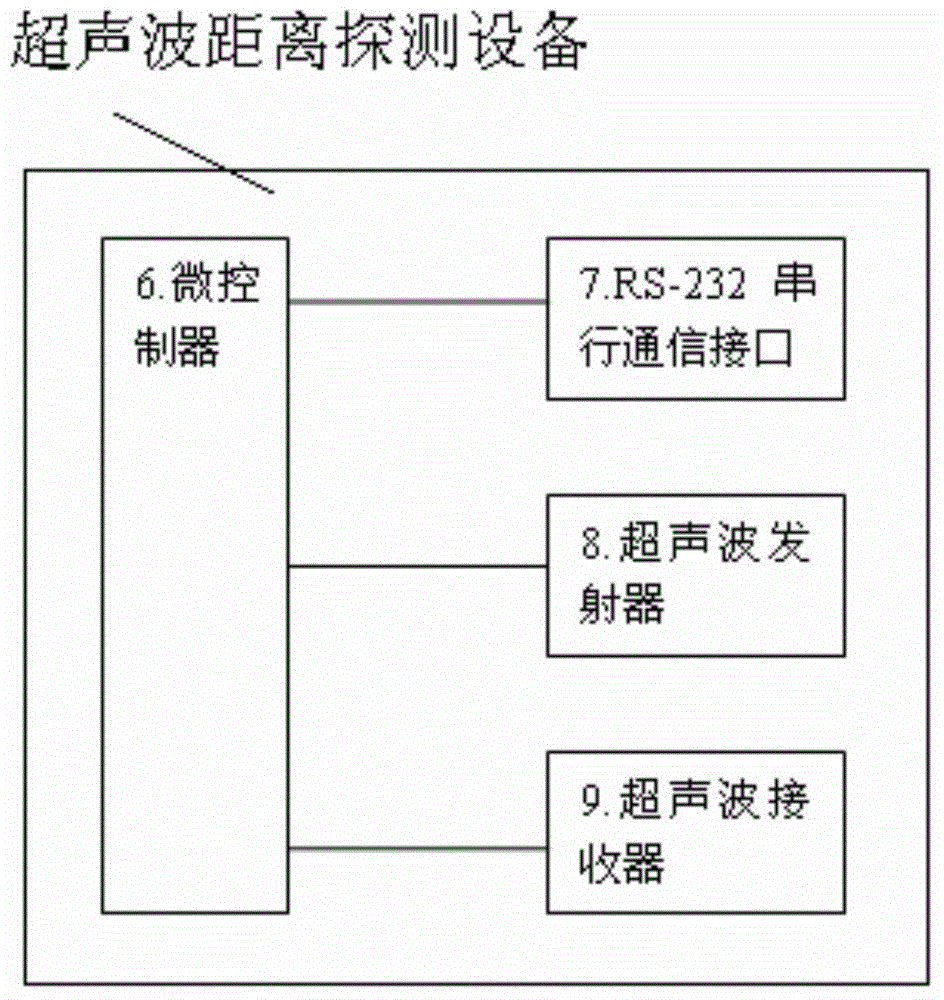

[0017] The embodiments of the underwater weld automatic identification system of the present invention will be described in detail below with reference to the accompanying drawings.

[0018] With the increasing shortage of land resources, people began to focus on underwater development. Underwater resources include marine resources and inland river resources. Due to the harshness of the underwater environment, only by improving the maturity of underwater welding technology can it be accelerated. Underwater resource development speed, so as to obtain more economic benefits.

[0019] There are three kinds of traditional underwater welding: dry method, wet method and partial dry method. Dry welding uses a large air chamber to cover the weldment, and the welding operator performs welding in the air chamber, which has the advantages of good safety, but has great limitations and is not widely used. Wet welding is that the welding operator directly welds under water, instead of arti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com