Method and device for improving underwater wet welding joint structure property

A microstructure performance, wet welding technology, applied in the direction of welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of increasing the burning loss of alloy elements, accelerating the crystallization speed of the welding pool, and fast cooling speed of the welding zone, etc., to achieve reduction Tendency to cold cracks, slow cooling rate, and reduce the effect of hardened structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for improving the microstructure and properties of underwater wet welded joints, comprising the steps of welding a welding sample with a welding torch underwater, and the step of preheating the welding surface of the welding sample before welding. Among them, preheating before welding adopts the method of adding intermediate frequency induction heating.

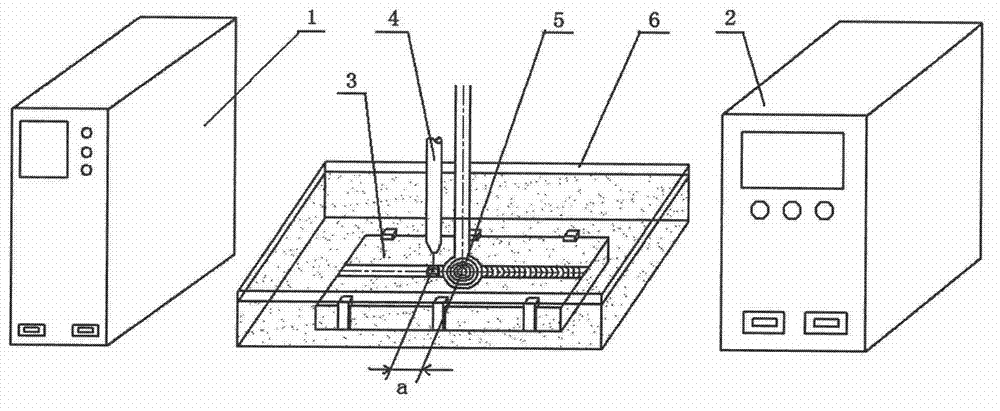

[0023] Such as figure 1 As shown, the device for improving the structure and performance of underwater wet welding joints corresponding to the above method includes an underwater welding power source 1, a welding torch 4 connected to the underwater welding power source 1, a welding sample 3, and a welding The welding water tank 6 outside the sample 3, the intermediate frequency induction heating coil 5 is placed on the upper surface of the welding sample 3, and the intermediate frequency induction heating coil 5 is controlled by the intermediate frequency induction heating power supply 2.

[0024] During weld...

Embodiment 2

[0026] A method for improving the microstructure and properties of underwater wet welded joints, comprising the steps of using a welding torch to weld a welding sample underwater, and performing pre-weld preheating and post-weld heat treatment on the welded surface of the welded sample . Among them, pre-welding preheating and post-welding heat treatment adopt the method of adding intermediate frequency induction heating.

[0027] Such as figure 1 As shown, the device for improving the structure and performance of underwater wet welding joints corresponding to the above method includes an underwater welding power source 1, a welding torch 4 connected to the underwater welding power source 1, a welding sample 3, and a welding The welding water tank 6 outside the sample 3, the intermediate frequency induction heating coil 5 is placed on the upper surface of the welding sample 3, and the intermediate frequency induction heating coil 5 is controlled by the intermediate frequency i...

Embodiment 3

[0030] A method for improving the microstructure and performance of underwater wet welded joints, comprising the steps of using a welding torch to weld a welding sample underwater, and the step of performing post-weld heat treatment on the welding surface of the welding sample. Among them, the post-weld heat treatment adopts the method of adding high-frequency induction heating.

[0031] Such as figure 1 As shown, the device for improving the structure and performance of underwater wet welding joints corresponding to the above method includes an underwater welding power source 1, a welding torch 4 connected to the underwater welding power source 1, a welding sample 3, and a welding The welding water tank 6 outside the sample 3, the high-frequency induction heating coil 5 is placed on the upper surface of the welding sample 3, and the high-frequency induction heating coil 5 is controlled by the high-frequency induction heating power supply 2.

[0032] During welding, the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com