Underwater pipeline dry type automatic welding method and welding device

An automatic welding and underwater pipeline technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of high labor intensity, low degree of automation, large engineering volume, etc., to improve construction efficiency, ensure welding quality, The effect of improving the feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

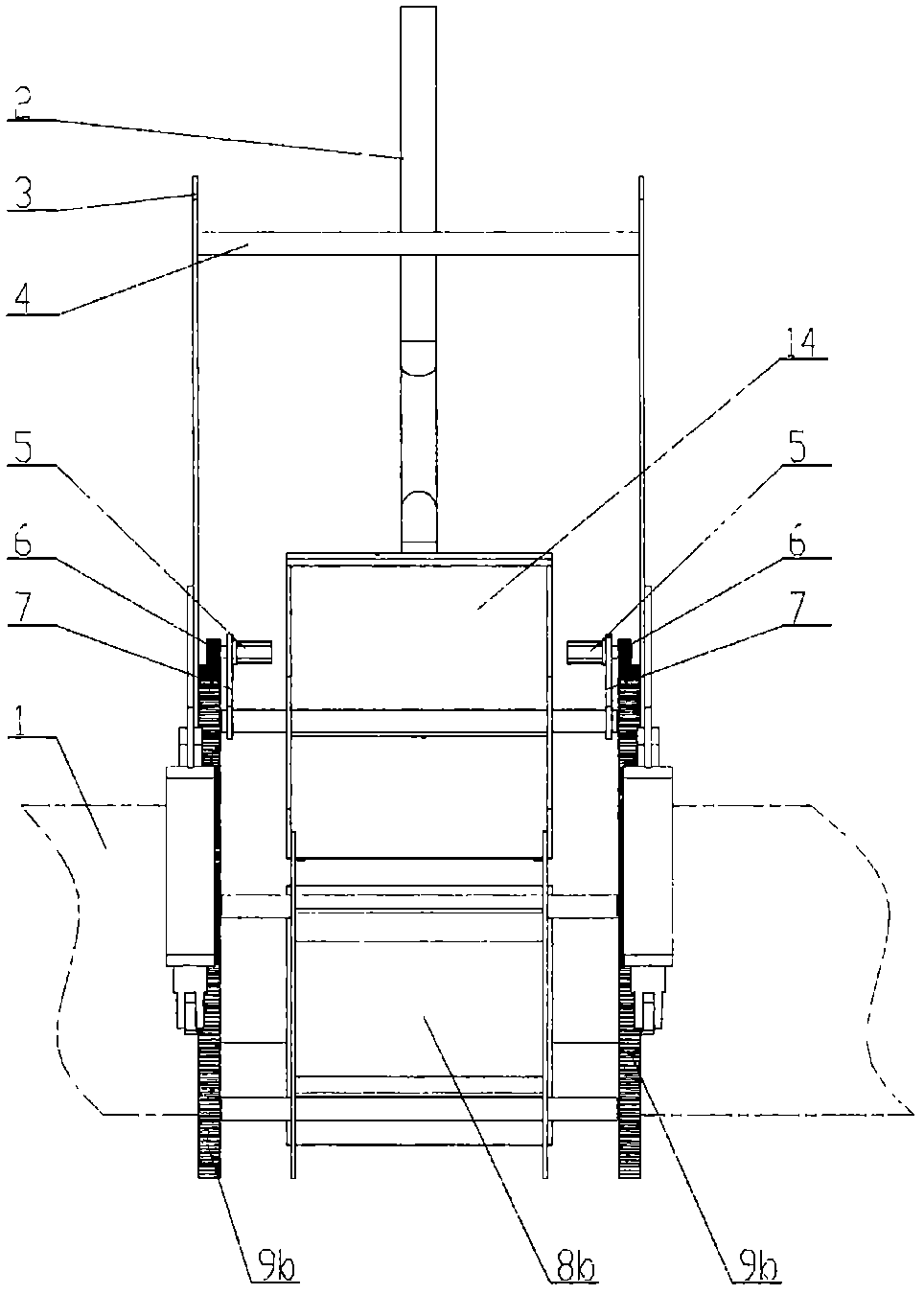

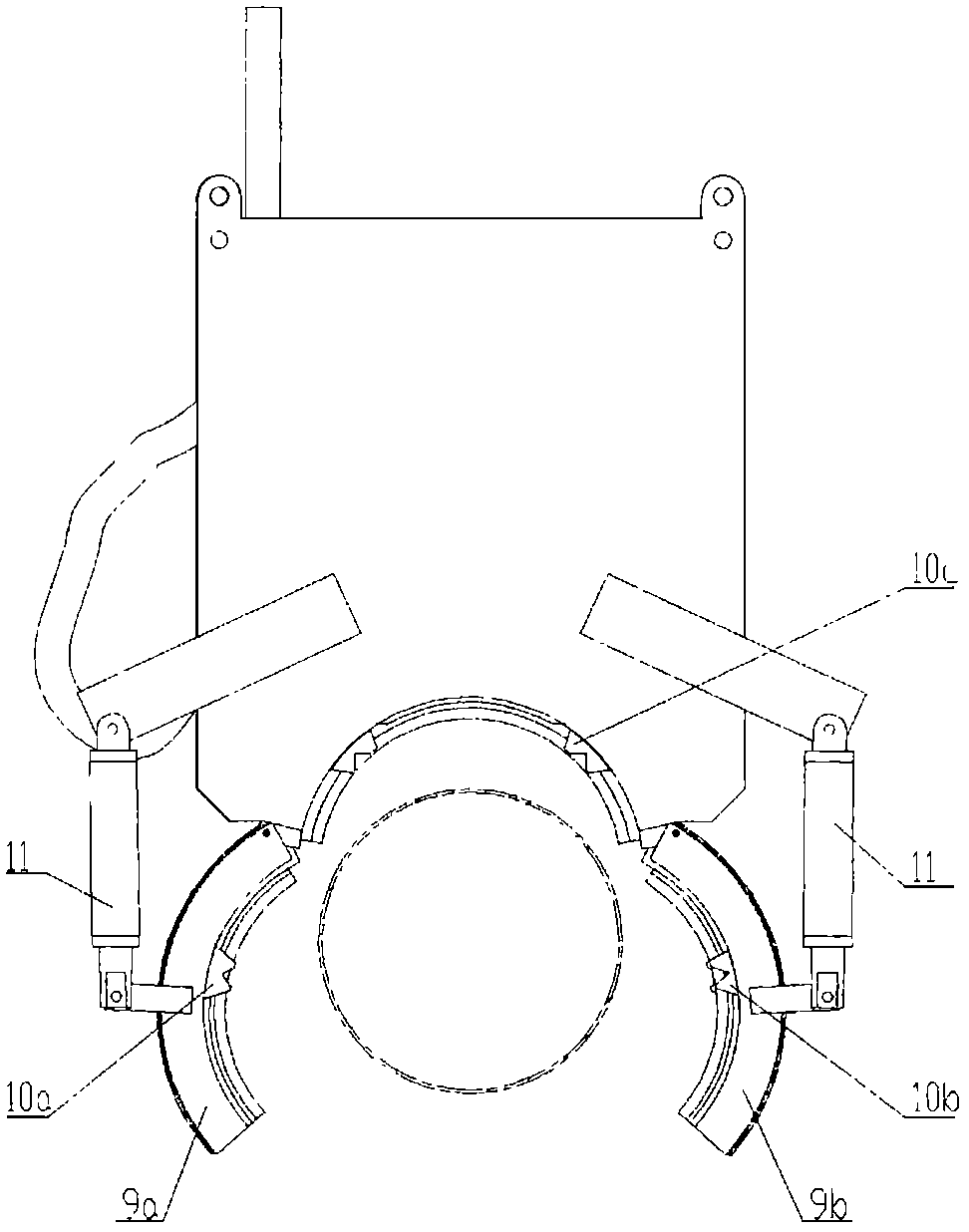

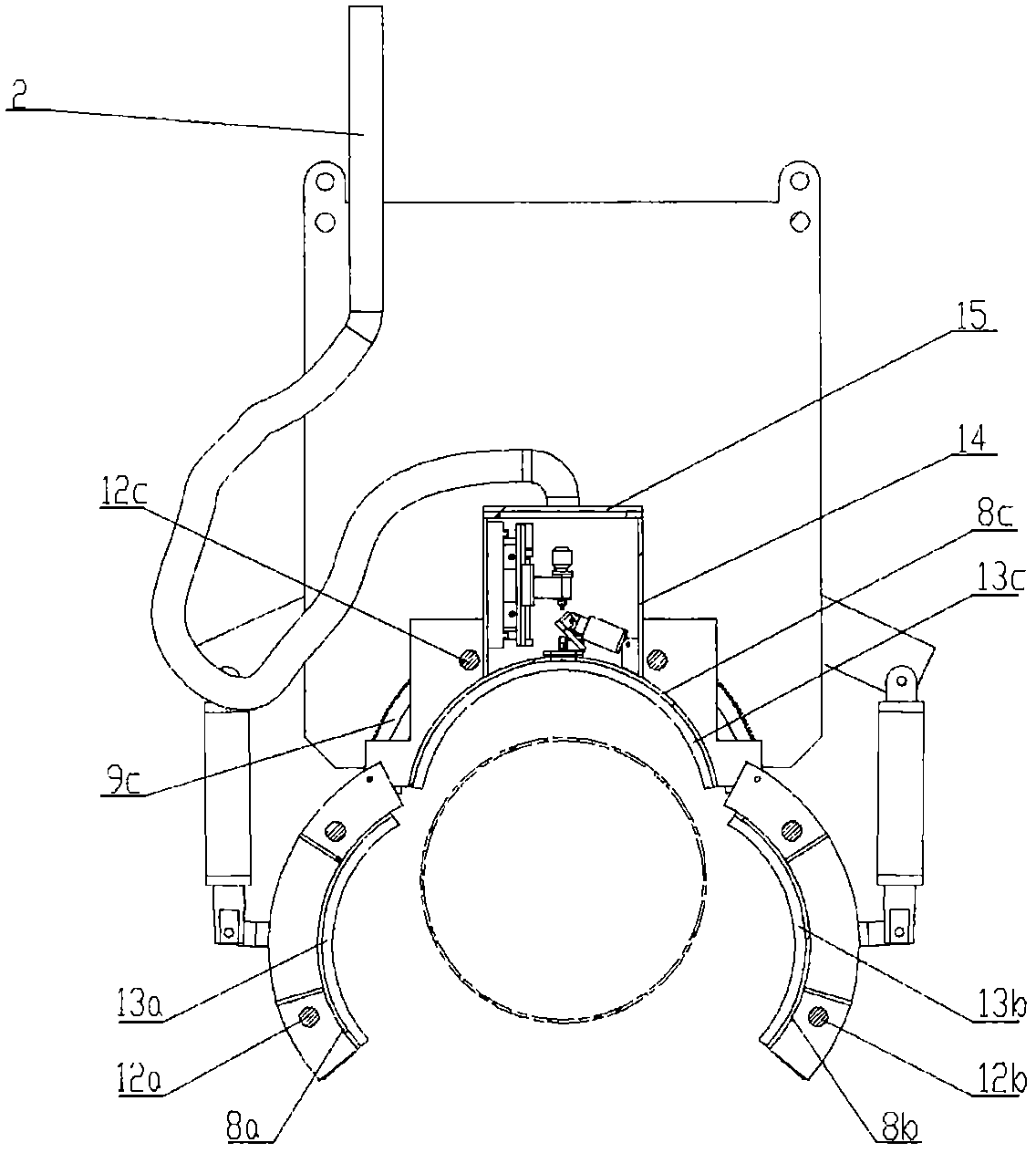

[0044] The underwater dry automatic welding method and welding device can adopt two-lobe clamping and three-lobe clamping methods, and the two methods are similar. This embodiment only uses the three-lobe clamping method for illustration.

[0045] Figure 1~4 It is a schematic diagram of various expressions when the present embodiment is in an open state, Figure 5-6 It is a schematic diagram of various expressions when the present embodiment is in a tight state, Figure 7 It is a schematic diagram of the installation, arrangement, and axial and radial movement of various functional components in the airtight working cabin of this embodiment. The underwater automatic welding method and the power supply, welding machine, air compressor, hydraulic system, master console and other water equipment required by the welding device are all installed on the water surface construction ship, and the umbilical cable has the power required by the underwater automatic welding device. Cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com