Combination device capable of achieving underwater laser welding and laser shot blasting

A laser shot peening and combined device technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of increasing the difficulty of operation and poor continuity, and achieve the effect of high processing efficiency, ingenious structure and strong continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

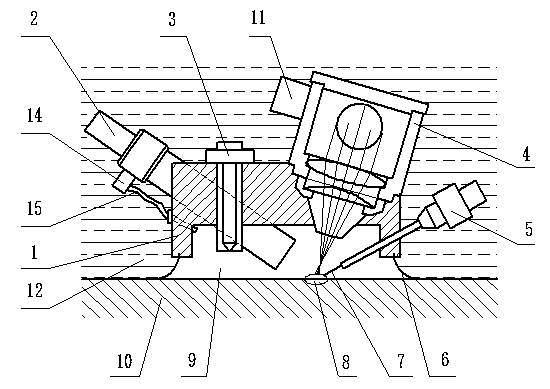

Embodiment 1

[0025] A prefabricated artificial crack with an opening width of 0.3 mm, a length of 10 mm, and a depth of 3 mm is made on 316L stainless steel, and a combined device is used for underwater laser welding of the crack. First connect the combination device with external equipment including control system, laser generator and oscilloscope, select 82 aluminum alloy as welding rod to fill into the electrode filling device 5, place the combination device underwater, cover the position to be processed, and make the sealing cover The mouth of the trachea 15 in the cavity 9 is always on the top to ensure that the air in the sealed cover cavity 9 can be discharged; the water-argon inlet 2 is controlled to fill the sealed cover cavity 9 with argon as a protective gas, and the water in the sealed cover cavity 9 is discharged. After emptying, the welding rod filling device 5 extends the welding rod to the position to be welded. The laser pulse wavelength is adjusted to 1060nm, the laser ene...

Embodiment 2

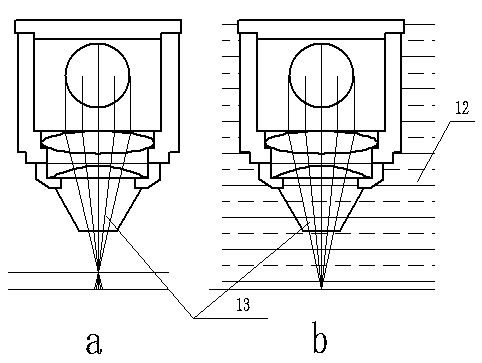

[0027] Laser peening on 304L stainless steel using a combination unit. First, connect the combination device with external equipment including control system, laser generator and oscilloscope, place the combination device underwater, cover the position to be processed, and make the mouth of the air pipe 15 in the cavity 9 of the sealed cover always on the top to ensure sealing The air in the cover cavity 9 can be discharged; open the valve 14, control the water and argon inlet 2 to fill the sealed cover cavity 9 with water as a confinement layer, and after the gas is discharged, adjust the laser pulse wavelength to 532nm, the pulse width to 8ns, and the spot diameter to 0.7mm , pulse energy 70mJ, energy density 7000 pulse / cm2 . After laser peening, the residual stress of 304L stainless steel increases significantly.

Embodiment 3

[0029] A 40×40mm piece of 304L stainless steel has a known defect of 0.2mm in size, which is detected by laser ultrasonic testing using a combination device. First connect the combination device with external equipment including control system, laser generator and oscilloscope, place the combination device underwater, cover the position to be detected, and make the mouth of the air pipe 15 in the cavity 9 of the sealed cover always on the top to ensure sealing The air in the cover cavity 9 can be discharged; open the valve 14, control the water and argon inlet 2 to fill the sealed cover cavity 9 with water as a confinement layer, after the gas is discharged, adjust the laser pulse wavelength to 1064nm, the laser energy to 45mJ / pulse, and move the combination The device completes the detection of the entire area, and locates the defect position by observing two oscilloscopes connected with the ultrasonic detection device 3 . When there is a defect between the laser irradiation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com