Ultrasonic-assisted underwater wet welding method

A wet welding, ultrasonic-assisted technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of aggravating oxygen embrittlement, oxygen hole tendency, complicated underwater welding process, aggravating arc shrinkage, etc., and achieve arc extinguishing The effect of reduced rate, high deposition efficiency, and fast melting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

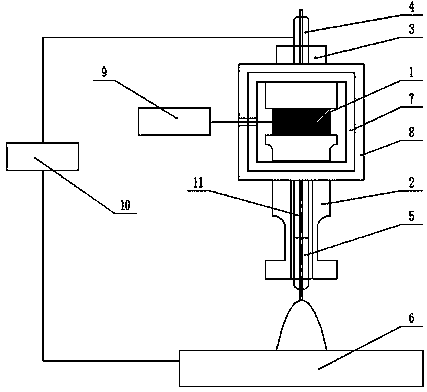

[0019] The present invention will be further described below in conjunction with accompanying drawing:

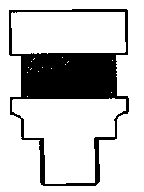

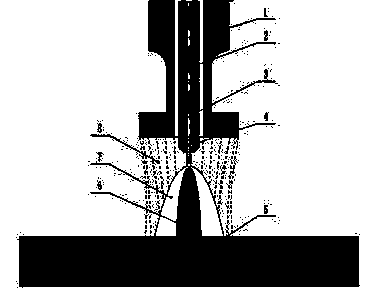

[0020] An ultrasonic-assisted underwater wet welding method, comprising an ultrasonic transducer, an ultrasonic horn, a conductive rod, a conductive tip, an ultrasonic power supply, and an underwater welding power supply, is characterized in that the ultrasonic transducer is sealed in a waterproof casing, and the casing The body is filled with aviation kerosene, the upper end of the ultrasonic horn passes through the waterproof casing and is connected to the lower end of the ultrasonic transducer through threads, the insulating sleeve passes through the waterproof casing, is inserted from the upper end of the ultrasonic transducer, and passes through the ultrasonic horn until the transducer The lower end of the horn, the insulating sleeve is equipped with a conductive rod and a conductive tip, the conductive tip is installed at the lower end of the insulating sleeve and part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com