Automatic flat welding device capable of shooting underwater arc and simulating different water depths

A water depth and automatic technology, applied in the direction of arc welding equipment, underwater operation equipment, welding equipment, etc., can solve the problem of unsatisfactory pressure chamber, etc., and achieve the effect of high accuracy and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

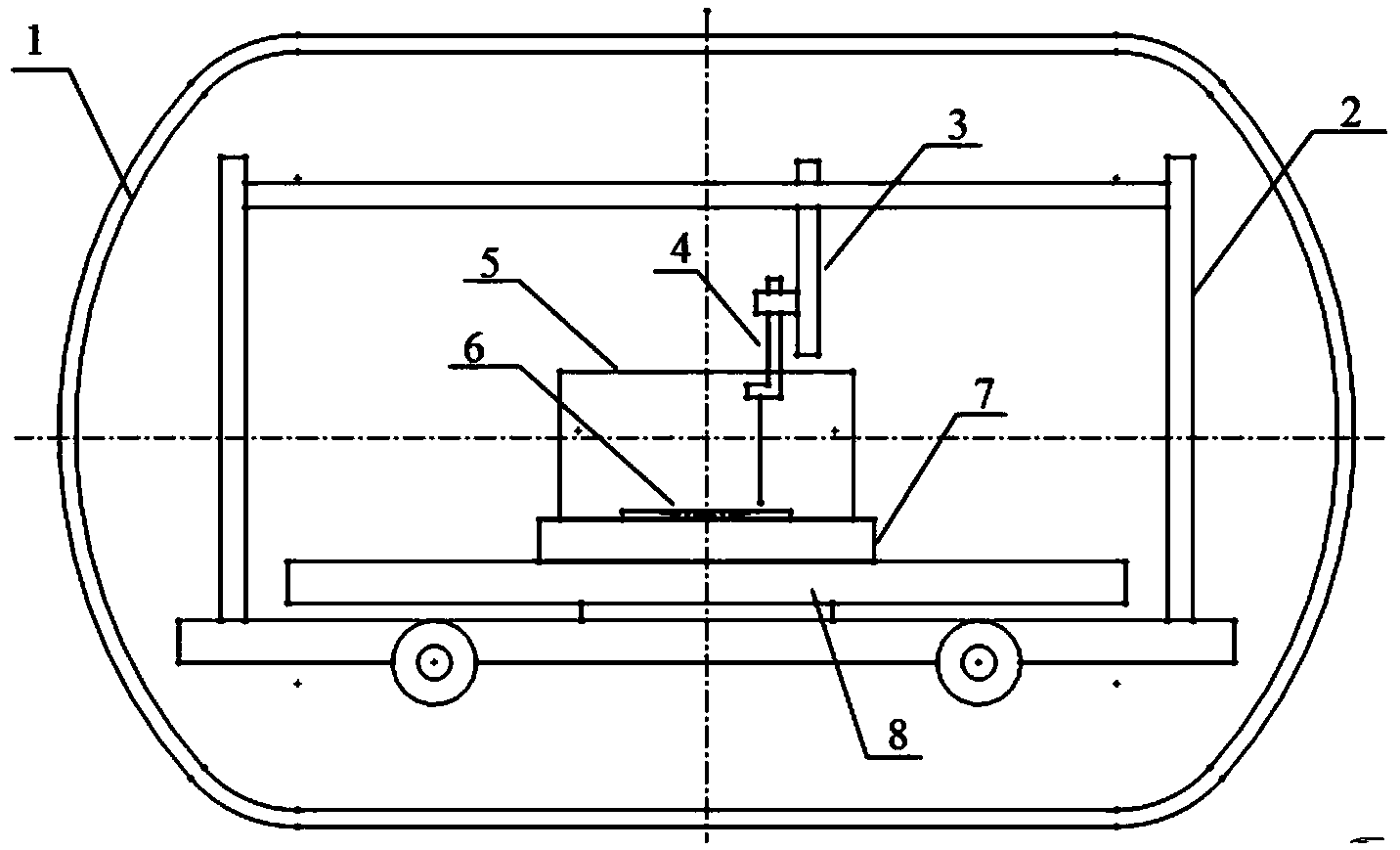

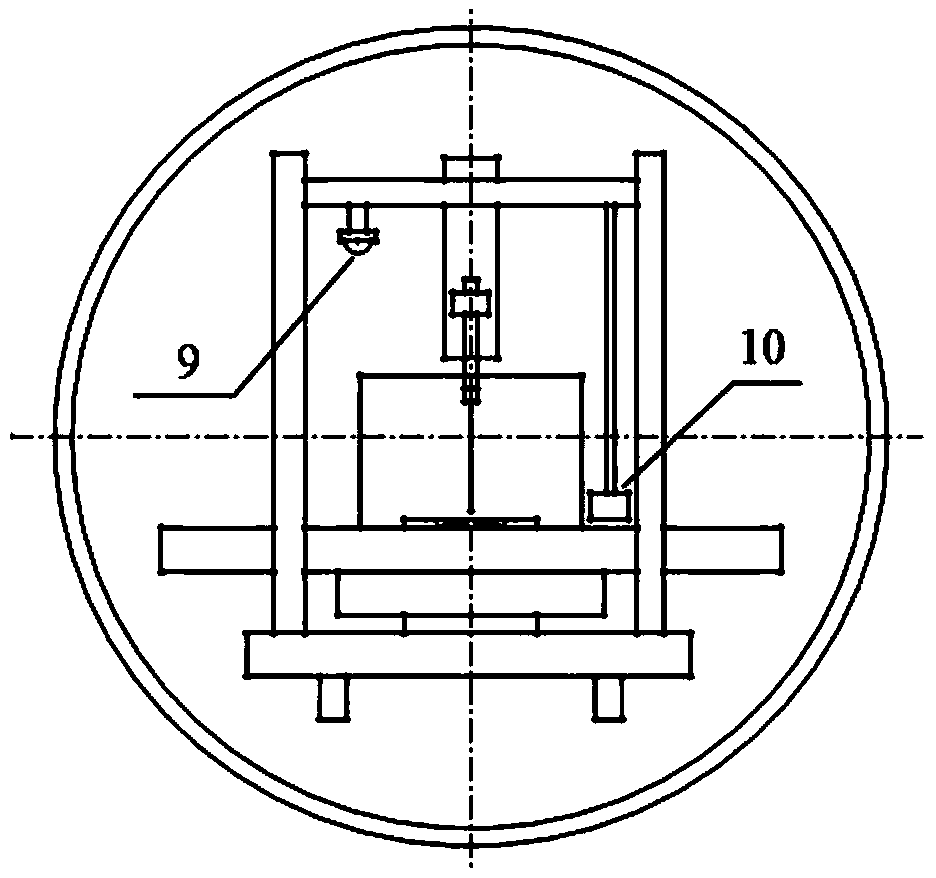

[0019] The structure of the automatic flat welding device capable of photographing underwater arcs and simulating different water depths of the present invention is described in conjunction with the accompanying drawings.

[0020] Such as figure 1 , 2 As shown, an automatic flat welding device of the present invention capable of photographing underwater arcs and simulating different water depths, the device includes a welding pressure chamber 1, a frame 2, an electrode / torch vertical feeding mechanism 3, and an electrode / torch clamp 4 , water tank 5, horizontal two-dimensional movement x-direction platform 7, horizontal two-dimensional movement y-direction platform 8, cabin global camera 9, high-speed camera 10;

[0021] The frame 2 is located in the welding pressure chamber 1, and the frame 2 is provided with sliding rails and sliding guide wheels that engage with each other, so that the frame 2 can enter and exit the welding pressure chamber 1 in parallel; the welding rod / t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com