Surfacial assembler

A technology of surface mounting machine and camera device, which is applied in the direction of conveyor objects, transportation and packaging, electrical components, etc., which can solve problems such as poor installation performance, longer moving distance, and damage to suction nozzles, so as to avoid mutual interference , Inhibition of damage to the suction nozzle and the effect of shortening the moving distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, best embodiments of the present invention will be described with reference to the accompanying drawings.

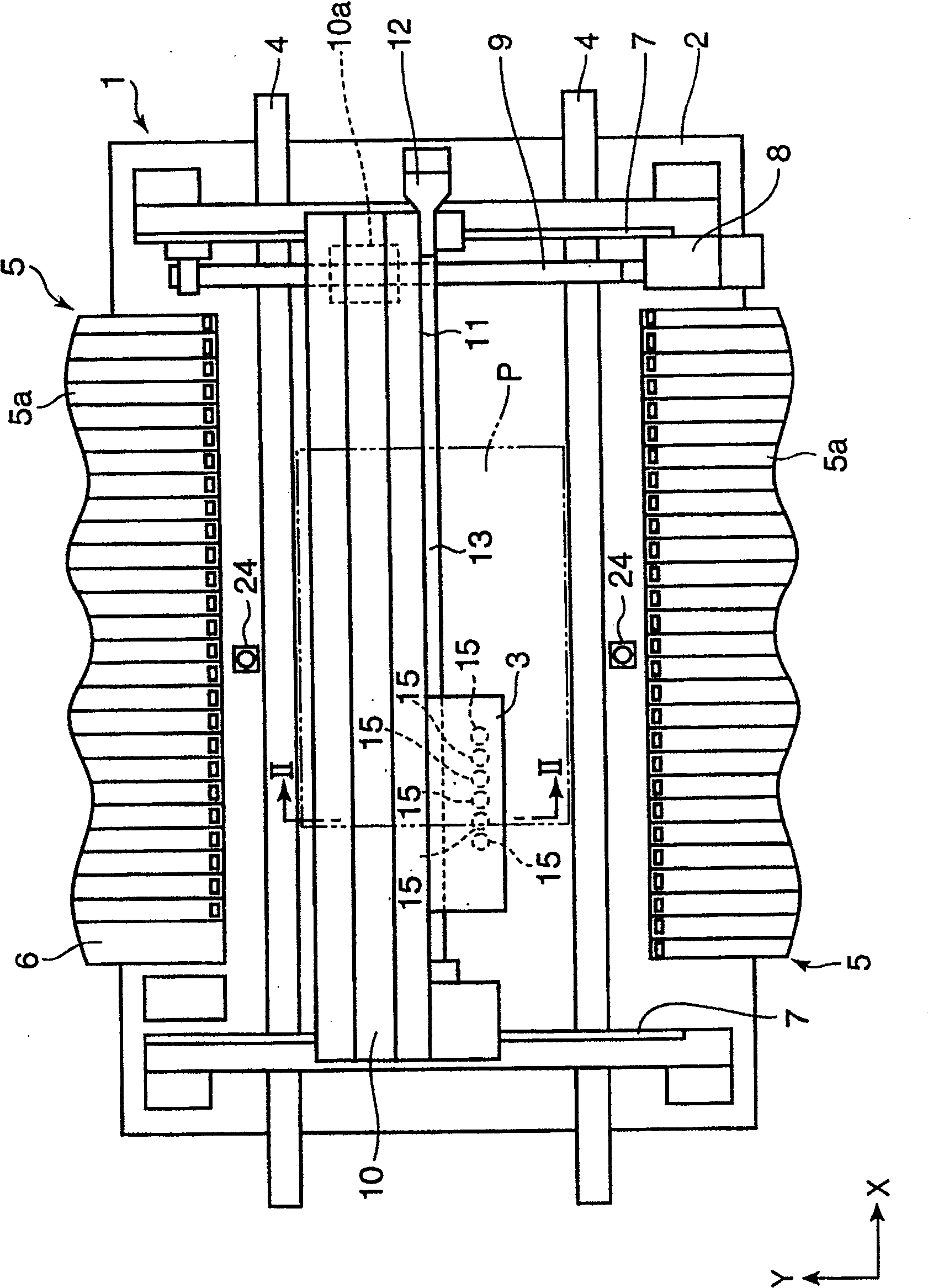

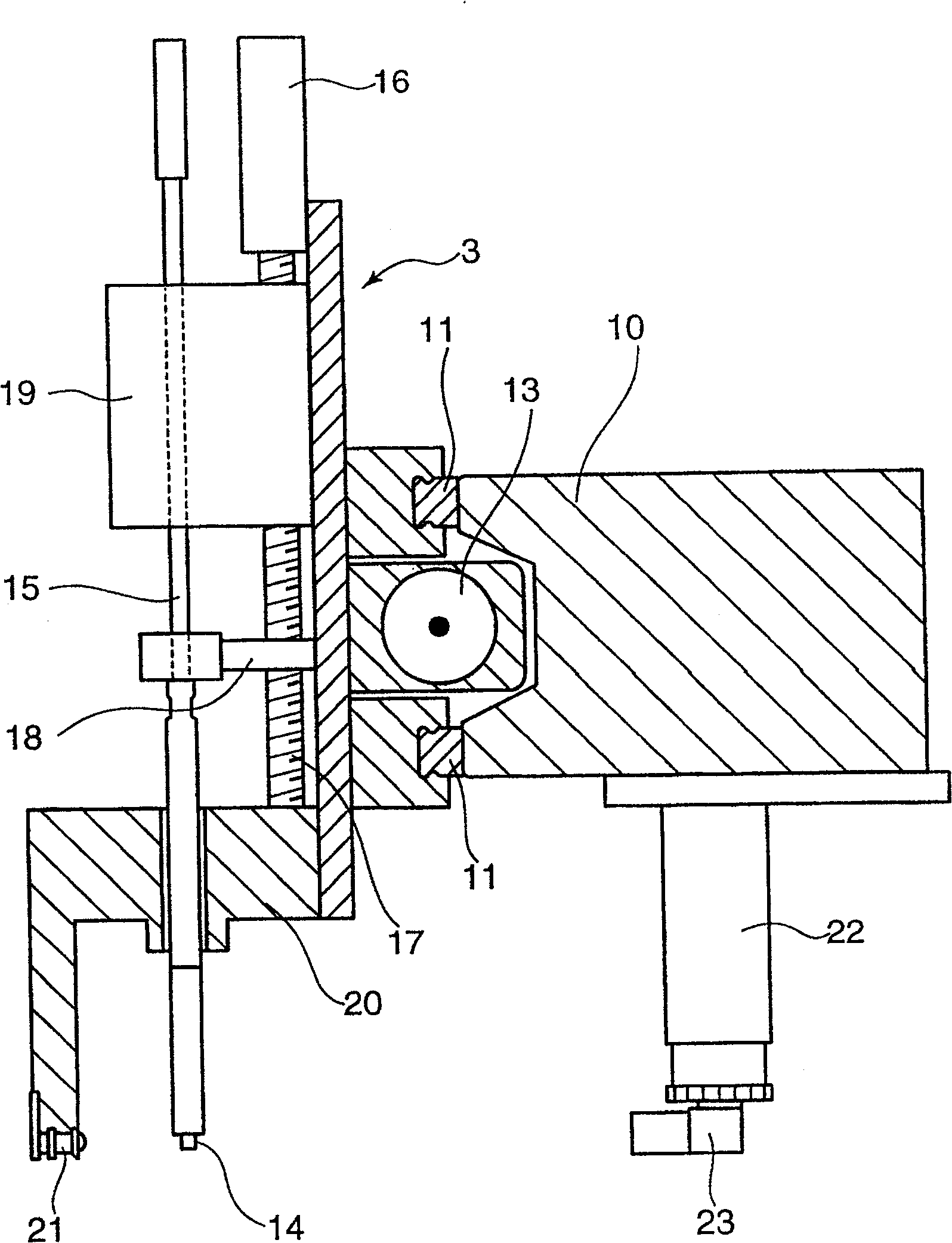

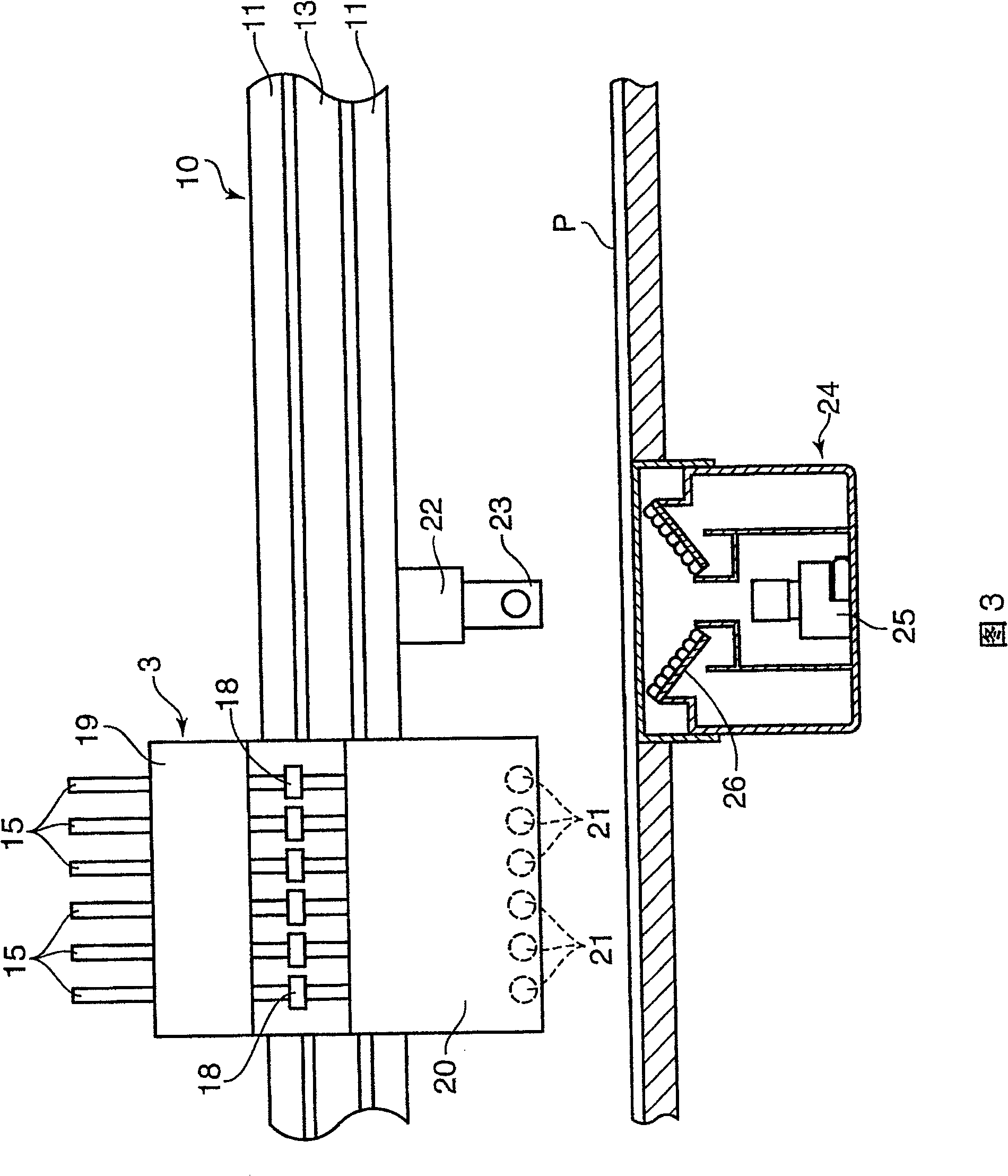

[0033] figure 1 is a partial plan view of the surface mounting machine of the present invention, figure 2 is omitted figure 1 A side cutaway view of part of the surface mount machine shown, image 3 is omitted figure 1 Front cutaway view of part of the surface mount machine shown.

[0034] The surface mounting machine mainly includes: the main mechanism part that mounts electronic components C (small chip components such as ICs, transistors, capacitors, etc.: refer to Fig. 9(a)) on the printed circuit board P by the operation of various parts of the mechanism 1; and a controller (control device) 30 (refer to Figure 4 ).

[0035] The main body mechanism unit 1 has a mounter body composed of a base 2 and the like, and a head unit (nozzle holding member) 3 movable relative to the mounter body.

[0036] On the above-mentioned base 2, there is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com