Underwater welding globular transfer real-time monitoring device and method

A droplet transfer and real-time monitoring technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of unable to clearly image, unable to separate droplets and bubbles, etc., and achieve good observation, convenient operation and wide applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

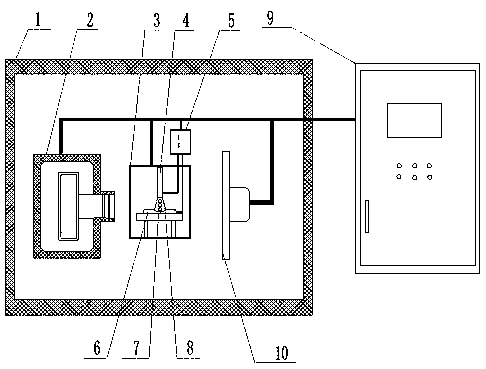

[0035] Embodiment 1: as figure 1 The shown x-ray receiver 10 is a flat panel detector. A real-time monitoring device for underwater welding droplet transition, which is mainly composed of a lead chamber 1, an X-ray source 2, a welding mechanism 3, a welding electrical signal acquisition unit 5, a remote control mechanism 9, and a flat panel detector. The X-ray source 2 and the flat-panel detector are respectively placed at both ends of the welding workpiece 6 to ensure that the center position of the emission end of the X-ray source 2 and the center position of the input end of the flat-panel detector remain on the same horizontal line, forming an angle of 180°. Adjust the position of the welding torch 4 in the welding mechanism 3 to ensure that the end of the welding torch 4 is within the observation field of view, so as to ensure that the arc region 8 and the welding droplet 7 are within the observation field of view during the welding process. Before the welding operation ...

Embodiment 2

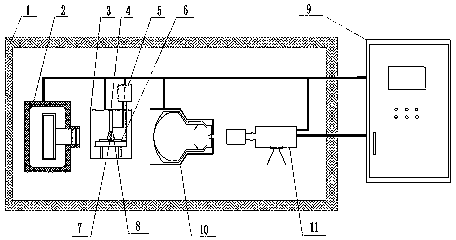

[0036] Embodiment 2: as figure 2 The shown x-ray receiver 10 is an image intensifier. The underwater welding droplet transition real-time monitoring device is mainly composed of a lead chamber 1, an X-ray source 2, a welding mechanism 3, a welding electrical signal acquisition unit 5, a remote control mechanism 9, a high-speed camera 11 and an image intensifier. The high-speed video camera 11 adopts an electric three-variable lens. The X-ray source 2 and the image receiver are respectively placed at both ends of the welding workpiece 6 to ensure that the center position of the emission end of the X-ray source 2 and the center position of the input end of the image receiver remain on the same horizontal line, forming an angle of 180°. Adjust the position of the welding torch 4 in the welding mechanism 3 to ensure that the end of the welding torch 4 is within the observation field of view, so as to ensure that the arc region 8 and the welding droplet 7 are within the observati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com