Multifunctional welding system of underwater welding robot

A welding system and underwater welding technology, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems of adapting to the underwater welding process, the difficulty of arc combustion stability, and difficulty in effective regulation, and achieve digital diagnosis, The effect of good scalability and good portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

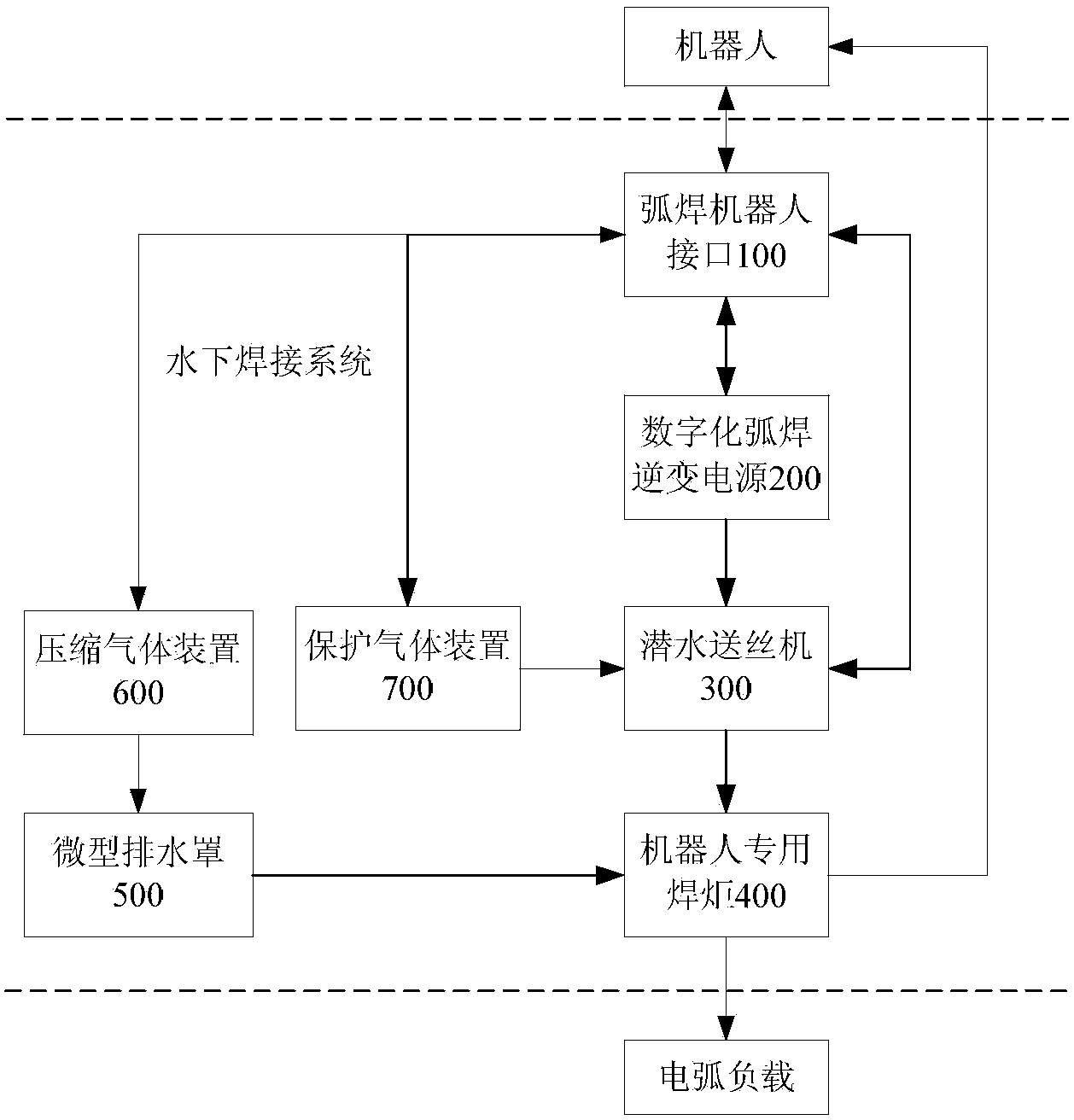

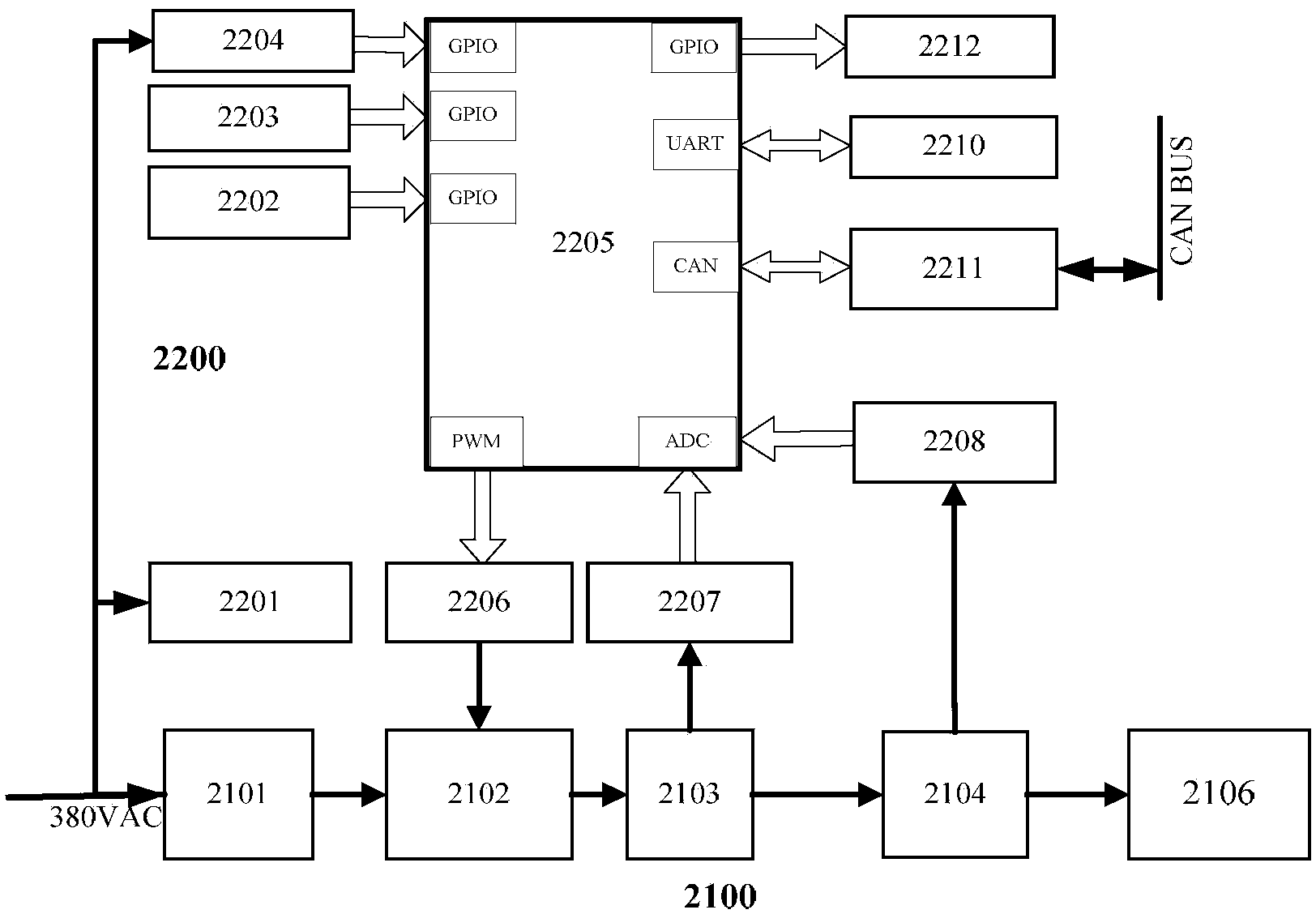

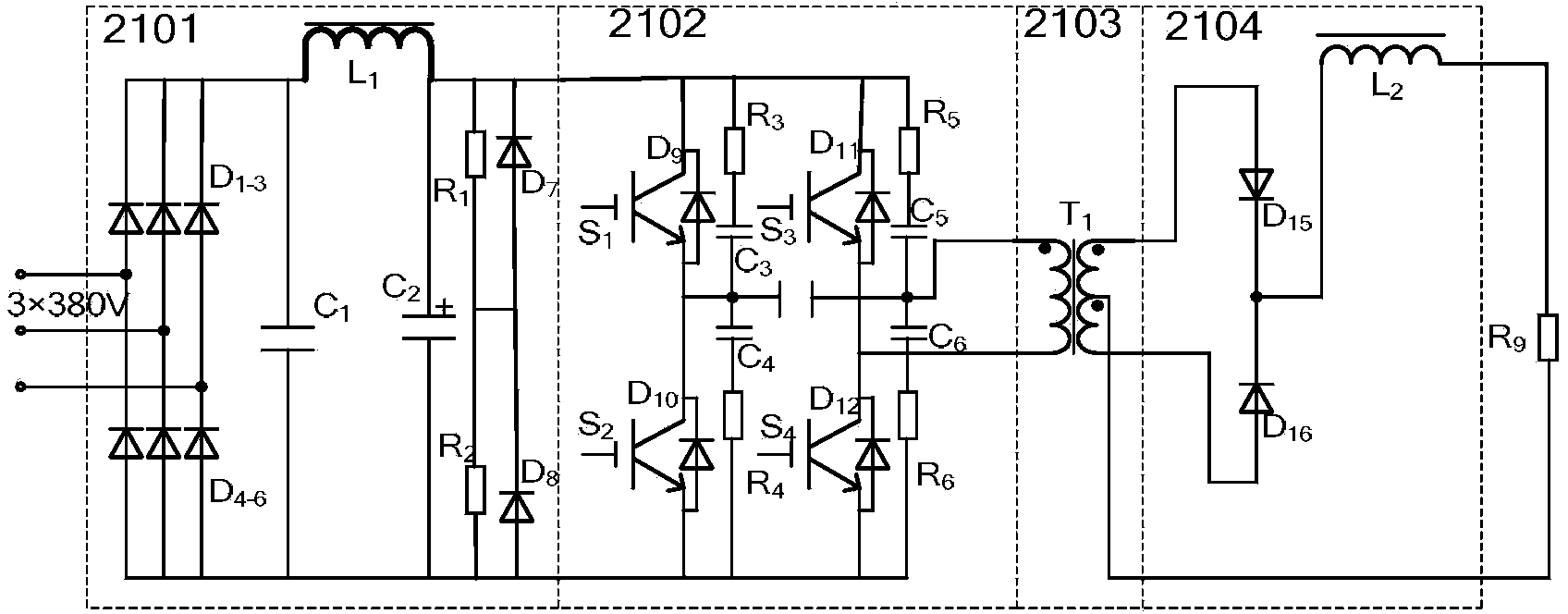

[0034] Such as figure 1 As shown, the underwater welding robot multifunctional welding system of the present invention includes an arc welding robot interface 100, a digital arc welding inverter power supply 200, a submersible wire feeder 300, a robot-specific welding torch 400, a miniature drainage cover 500, and a compressed gas device 600 And the shielding gas device 700; wherein, the arc welding robot interface 100, the digital arc welding inverter power supply 200, the submersible wire feeder 300 and the robot-specific welding torch 400 are connected in sequence. One end of the arc welding robot interface 100 connected to the robot through the CAN bus is connected to the submersible wire feeder 300, and is respectively connected to the compressed gas device 600 and the shielding gas device 700; The cover 500 is connected, one end of which is connected with the arc load one; the compressed gas device 600 is connected with the miniature drainage cover 500 , and the protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com