3D (three-dimensional) printer with inclinable machine body

A 3D printer and machine body technology, applied in the field of 3D printing technology, can solve problems such as incompatibility, incompatibility, and gravity limitations of 3D printers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

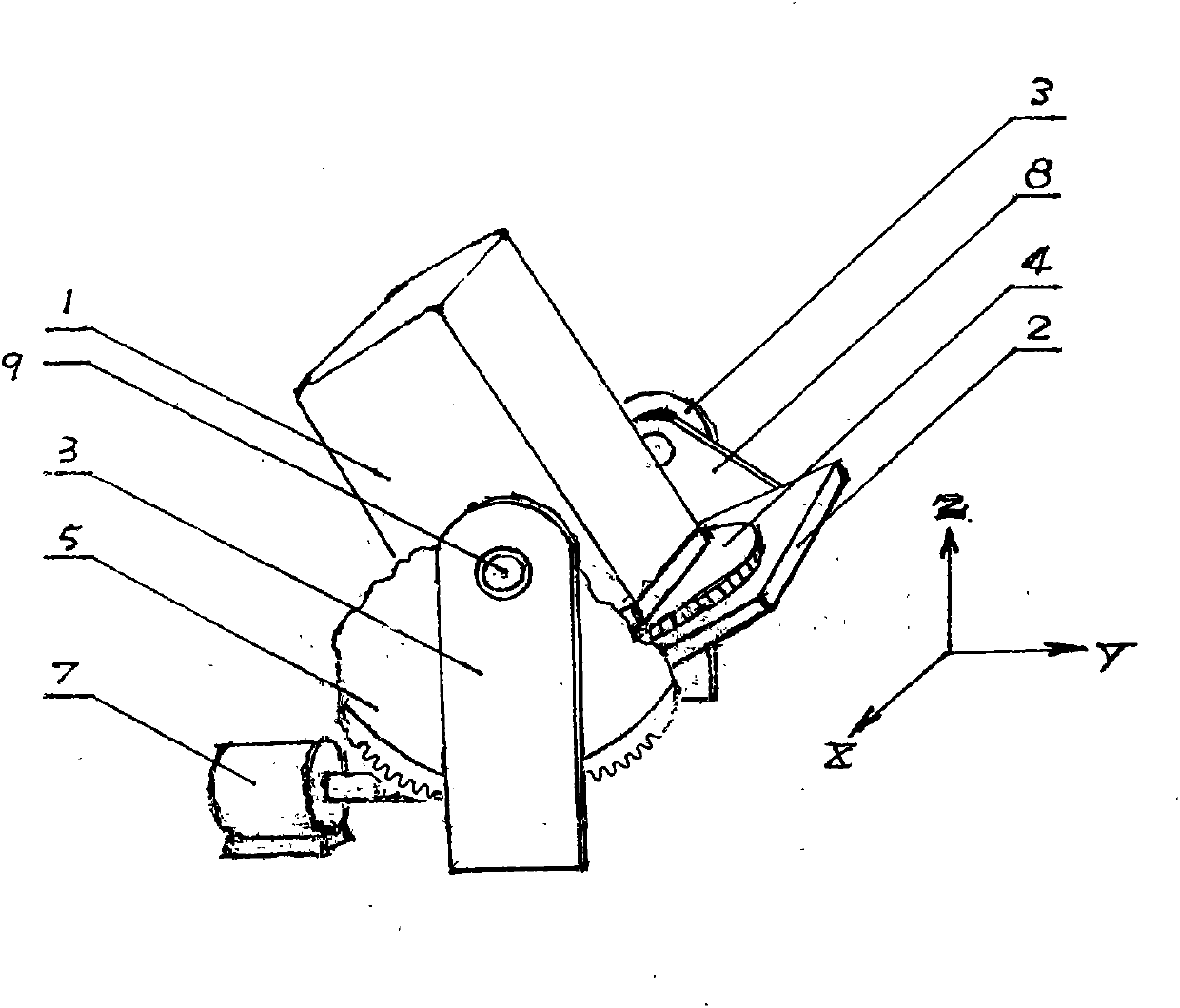

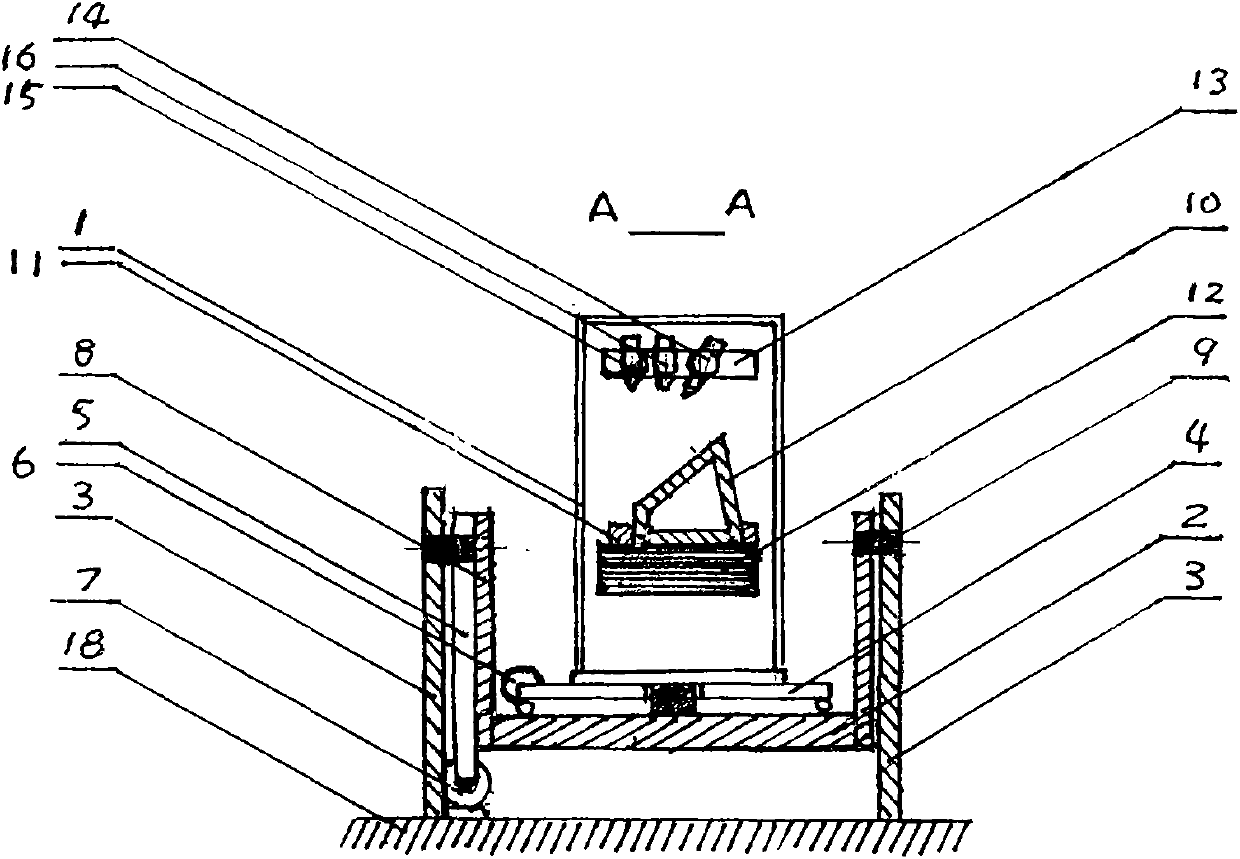

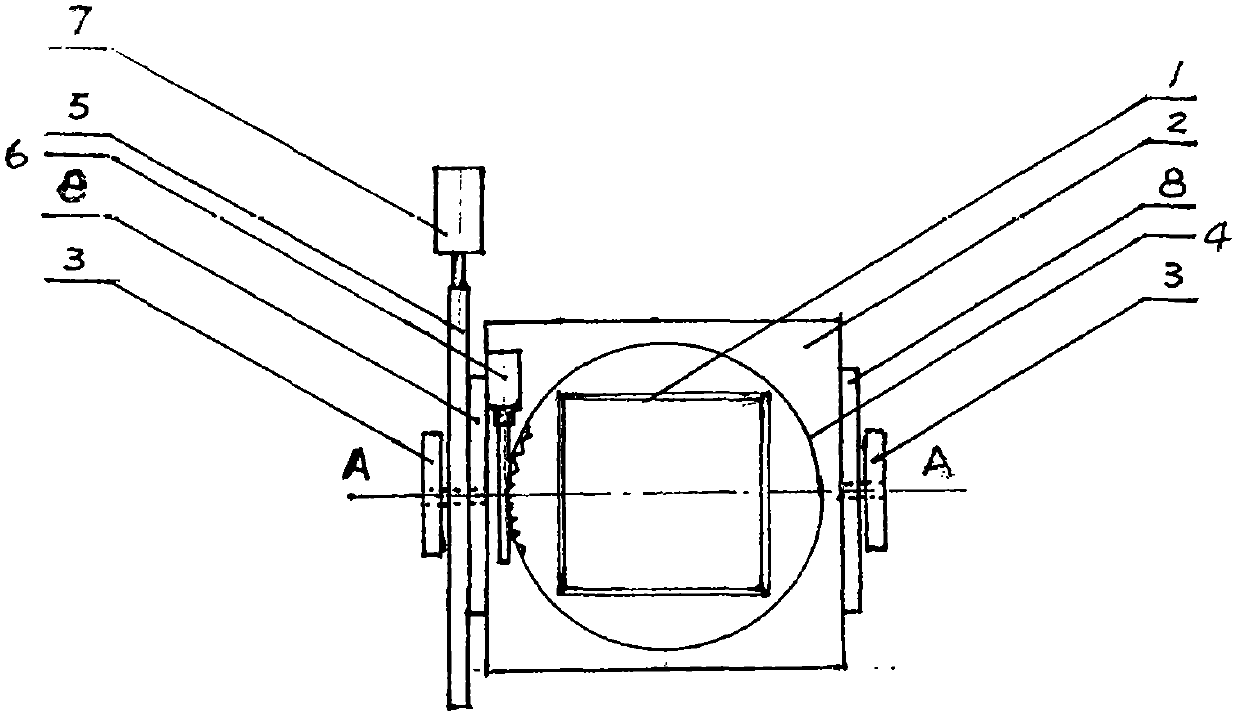

[0049] Embodiment 1: 3D printer of the present invention for processing any hollow polyhedron workpiece:

[0050] Any hollow polyhedron workpiece (10) such as figure 2 and Figure 5 As shown, after the selected position is placed on the main workbench (12) of the 3D printer of the present invention, there is still an angle γ between the normal vector N of a certain surface and the Z axis, which is less than the critical angle γ c , ( Figure 5 ), so, when using the 3D printer of the present invention to print the workpiece (10) that includes the sheet of this surface, the rotating platform (4) placed on the main body (1) of the 3D printer of the present invention is controlled by a worm gear motor device ( 4,6) drive, rotate an angle or β′( Figure 7 ), the surface is in place to a position perpendicular to the deflection plane of the Z-axis (around the X-axis) of the 3D printer base of the present invention; thereafter, the base platform (2) is driven by a worm gear moto...

Embodiment 2

[0052] Embodiment 2: 3D printer of the present invention for processing multilayer honeycomb structure workpiece:

[0053] The multi-layer honeycomb structure workpiece to be printed can be in any shape, such as the hexagonal honeycomb structure of bees, the square lattice honeycomb structure, and so on. In this embodiment, a workpiece with a multi-layer grid honeycomb structure is selected to describe the 3D printer with a tiltable body of the present invention. When printing a multi-layer honeycomb structure workpiece ( Figure 6 , 610), the 3D printer of the present invention can complete the printing of the entire workpiece in a relatively simple manner. First, in step ①, the main body (1) of the 3D printer of the present invention prints the first layer of honeycomb structure (610a) of the multi-layer honeycomb structure workpiece (610) on the workbench (12, 612) in an upright form without tilting; then The 2nd step, continue in this way, print the selected edge thin la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com