Preparation method of polybutadiene latex with low gel content, and prepared polybutadiene latex

A polybutadiene latex, low-gel technology, applied in the polymer field, can solve problems such as inability to use, and achieve the effects of increasing the volume, increasing the distance between chains, and reducing the reaction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of Allyl Polyether Monomer

[0030] The preparation of the allyl polyether monomer in this example includes the following steps: 58g of allyl alcohol is added to the reaction kettle, the temperature is raised to 100°C, and 348g of propylene oxide, 132g of ethylene oxide and 1.61g of KOH are added under stirring. Polymerization. When the conversion rate of propylene oxide is 99.1%, add phosphoric acid in an equimolar amount to KOH, stir evenly, and remove the generated water under the conditions of 110°C and 5Kpa. When the water content in the reactant is 0.04%, allyl is obtained base polyether monomer.

Embodiment 2-5

[0031] Example 2-5 Preparation of Allyl Polyether Monomer

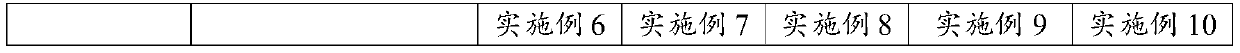

[0032] The differences between Examples 2-5 and Example 1 are shown in Table 1, and the rest of the raw materials, experimental conditions and reaction steps are the same as in Example 1.

[0033] The difference between table 1 embodiment 2-5 and embodiment 1

[0034] Example 1 Example 2 Example 3 Example 4 Example 5 Reaction temperature / ℃ 100 110 120 120 130 Allyl alcohol (g) 58 58 58 58 58 Propylene oxide (g) 348 1044 522 1044 696 Ethylene oxide (g) 132 132 176 264 132 KOH(g) 1.61 8.64 7.56 12.29 4.43 Phosphoric acid (g) 2.82 15.12 13.23 21.51 7.75

Embodiment 6

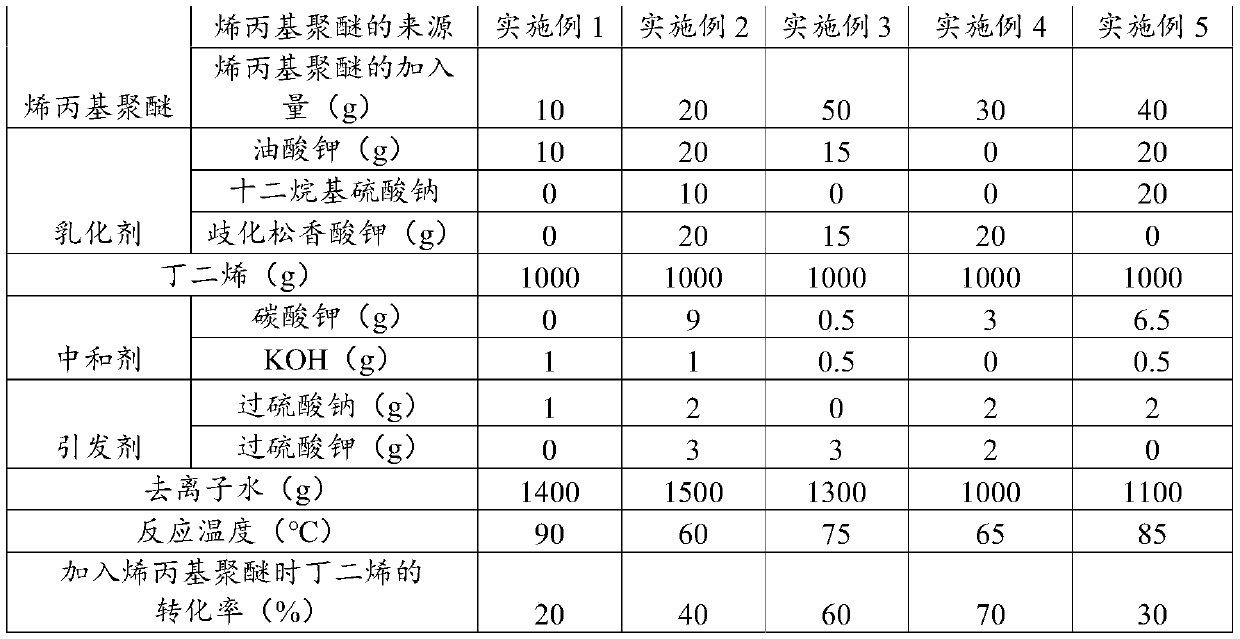

[0035] Example 6 Preparation of butadiene latex

[0036] The preparation of the butadiene latex in this example comprises the following steps: adding 10 g of potassium oleate, 1000 g of butadiene, 1 g of KOH, 1 g of sodium persulfate and 1400 g of deionized water into the reactor, raising the temperature to 80° C., and carrying out the polymerization reaction. When the conversion rate of butadiene was 20%, 10 g of the allyl polyether prepared in Example 1 was added for polymerization and reaction, and polybutadiene latex was obtained when the conversion rate of butadiene was 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com