Organosilane coupling agent modified ultraviolet curing material

A silane coupling agent and curing material technology, applied in the field of materials, to achieve the effects of thermal stability and water contact angle performance improvement, strong adhesion, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of ultraviolet curing material, it adopts following method to prepare:

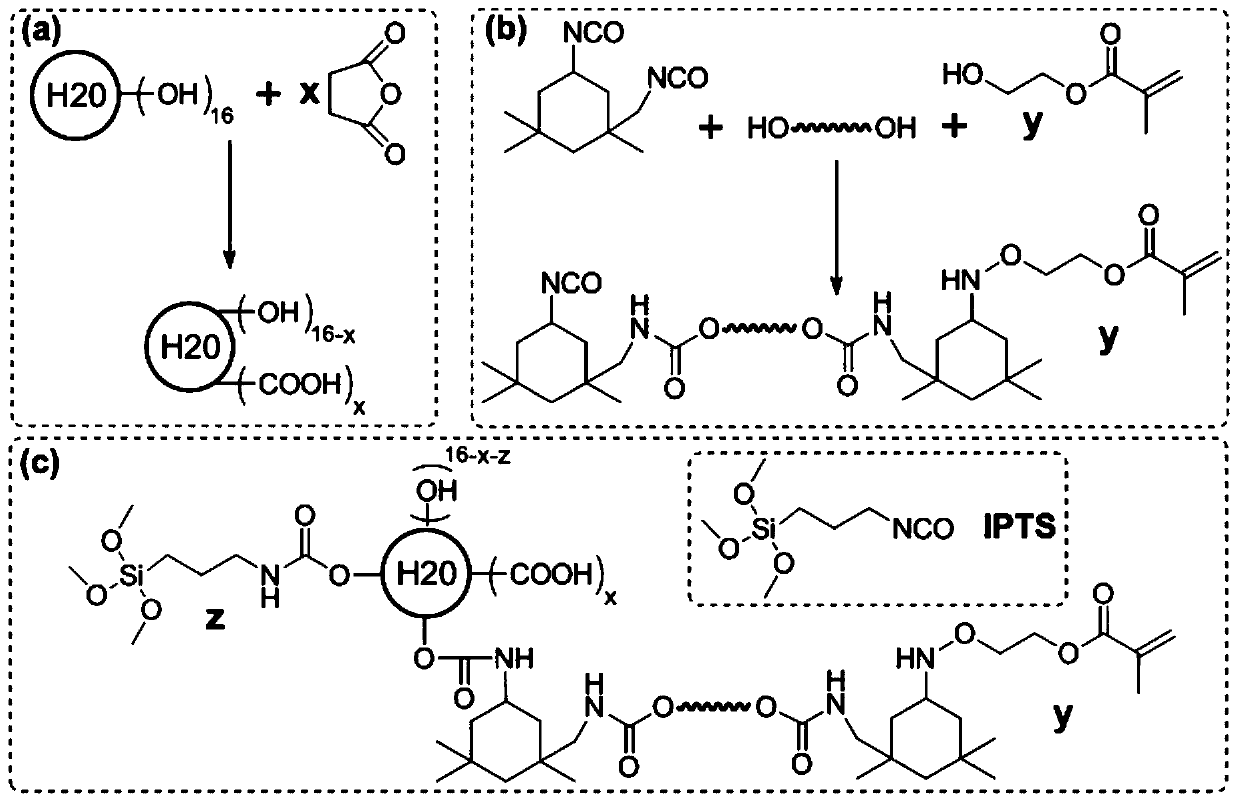

[0037] (1) Water-borne hyperbranched polyester Boltorn H20

[0038] Aqueous modification of hyperbranched polyester grafted carboxyl groups was carried out by transesterification reaction. In there-necked flask, add 20g (11.4mmol) hyperbranched polyester Boltorn H20 and 6.86g (68.4mol) succinic anhydride, then add 100ml 1,4-dioxane for dissolving, then add suitable transesterification catalyst tin chloride, The temperature of the reaction system was raised to 100° C., and the reaction was carried out at constant temperature for 24 hours. After the reaction is completed, the solvent and a small amount of water are removed by distillation under reduced pressure to obtain the carboxyl-modified hyperbranched polyester BoltornH20.

[0039] (2) Synthesis of methacrylate-based modified polyether-based polyurethane prepolymer

[0040] Anhydrous 1,4-dioxane was added into the three-necked flask, n...

Embodiment 2

[0044] A UV-curable material modified by an organosilane coupling agent, which is prepared by the following method:

[0045] (1) Water-borne hyperbranched polyester Boltorn H20

[0046] Aqueous modification of hyperbranched polyester grafted carboxyl groups was carried out by transesterification reaction. In there-necked flask, add 20g (11.4mmol) hyperbranched polyester Boltorn H20 and 6.86g (68.4mol) succinic anhydride, then add 100ml 1,4-dioxane for dissolving, then add suitable transesterification catalyst tin chloride, The temperature of the reaction system was raised to 100° C., and the reaction was carried out at constant temperature for 24 hours. After the reaction is completed, the solvent and a small amount of water are removed by distillation under reduced pressure to obtain the carboxyl-modified hyperbranched polyester BoltornH20.

[0047] (2) Synthesis of methacrylate-based modified polyether-based polyurethane prepolymer

[0048] Anhydrous 1,4-dioxane was added...

Embodiment 3

[0052] A UV-curable material modified by an organosilane coupling agent, which is prepared by the following method:

[0053] (1) Water-borne hyperbranched polyester Boltorn H20

[0054] Aqueous modification of hyperbranched polyester grafted carboxyl groups was carried out by transesterification reaction. In there-necked flask, add 20g (11.4mmol) hyperbranched polyester Boltorn H20 and 6.86g (68.4mol) succinic anhydride, then add 100ml 1,4-dioxane for dissolving, then add suitable transesterification catalyst tin chloride, The temperature of the reaction system was raised to 100° C., and the reaction was carried out at constant temperature for 24 hours. After the reaction is completed, the solvent and a small amount of water are removed by distillation under reduced pressure to obtain the carboxyl-modified hyperbranched polyester BoltornH20.

[0055] (2) Synthesis of methacrylate-based modified polyether-based polyurethane prepolymer

[0056] Anhydrous 1,4-dioxane was added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com