Preparation method of polybutadiene latex

A technology of polybutadiene latex and liquid polybutadiene, which is applied in the field of ABS resin materials, can solve the problems of increased production of butadiene dimers, affecting the VOC content of products, and poor resin toughening effect, etc., achieving excellent Resin toughening effect, reduction of polybutadiene sticky matter, good impact resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

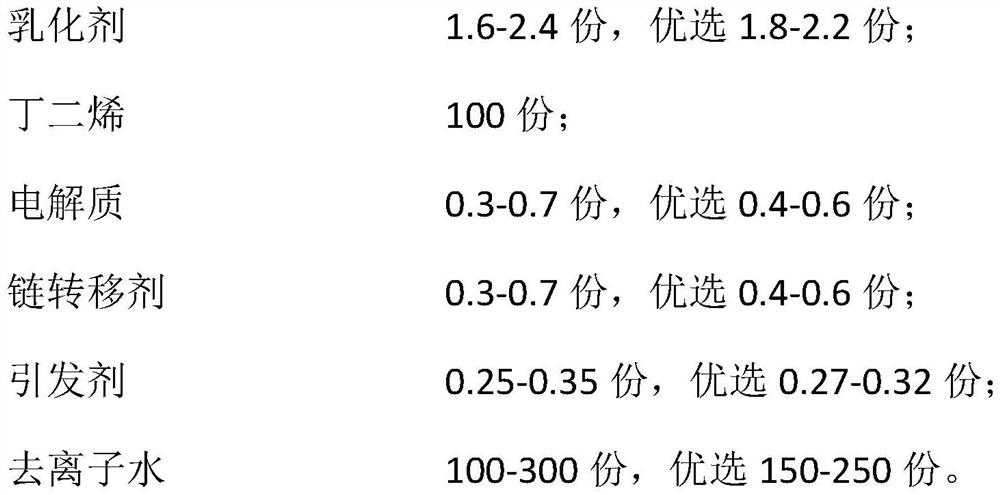

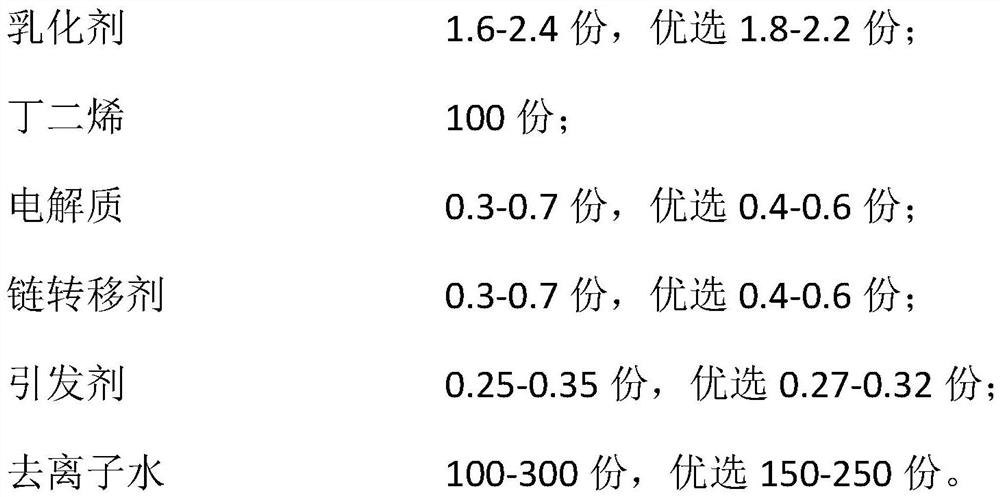

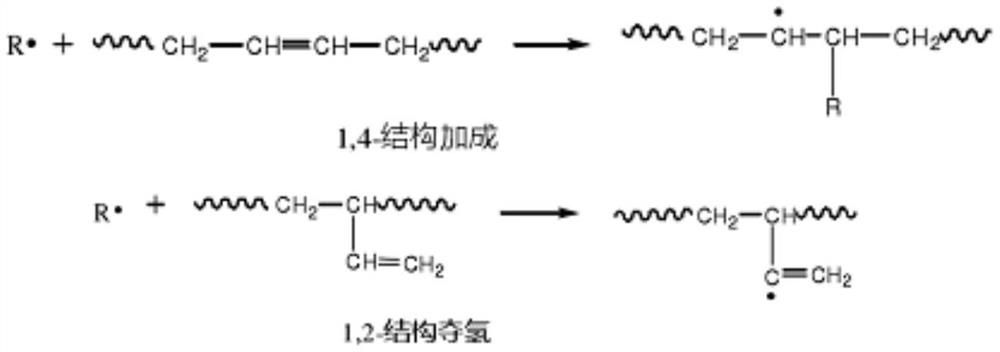

Method used

Image

Examples

Embodiment 1

[0053] (1) Potassium oleate 0.9g, disproportionated abietate potassium 1.1g, butadiene 100g, potassium carbonate 0.6g and tertiary dodecyl mercaptan (TDM) 0.7g, deionized water 250g are added in the reactor, Heating to 65°C, adding 0.25 g of potassium persulfate to initiate emulsion polymerization reaction, after 7 hours of reaction, the conversion rate of butadiene in the kettle was 73.5%, and the reaction was stopped, and unreacted butadiene was removed by vacuum flashing to obtain latex particles A small particle size polybutadiene latex emulsion with a diameter of 87nm.

[0054] (2) Heat the reactor to 70°C, add 10g of 110 liquid polybutadiene (purchased from Evonik, number average molecular weight 2600, 1,2-vinyl content 1%, 1,4-cis content 75%), 0.1g sodium linoleate, 0.1g stearic acid Sodium, continue to react for 2h, stop the reaction to obtain a polybutadiene latex emulsion with a particle size of 101.2nm.

[0055] The gel content of the polybutadiene latex was 27%...

Embodiment 2

[0057] (1) Add 0.7 g of sodium stearate, 0.9 g of sodium dodecylbenzenesulfonate, 100 g of butadiene, 0.4 g of sodium sulfite, 0.5 g of n-octadecyl mercaptan, and 100 g of deionized water into the reactor, Heating to 60°C, adding 0.35 g of cumene hydroperoxide to initiate emulsion polymerization reaction, after 6 hours of reaction, the conversion rate of butadiene in the kettle was 66.3%, and the reaction was stopped, and the unreacted butadiene was removed by vacuum flashing. A small particle size polybutadiene latex emulsion with a particle size of 82.4 nm was obtained.

[0058] (2) Cool the reactor to 55°C, add 20g of 130 liquid polybutadiene (purchased from Evonik, number average molecular weight 4600, 1,2-vinyl content 1%, 1,4-cis content 77%) and 0.1g sodium dodecylbenzenesulfonate, continued After reacting for 1.5 h, stop the reaction to obtain a polybutadiene latex emulsion with a particle size of 95.3 nm.

[0059] The gel content of the polybutadiene latex was 31.2...

Embodiment 3

[0061] (1) Add 0.9g of potassium stearate, 0.9g of potassium oleate, 100g of butadiene, 0.5g of potassium phosphate, 0.6g of n-octyl mercaptan, and 300g of deionized water into the reaction kettle, heat to 70°C, and add 0.27g of tert-butyl hydroperoxide initiates the emulsion polymerization reaction, and the butadiene conversion rate in the kettle is 71.7% after reacting for 6.5h, the reaction is stopped, and the unreacted butadiene is removed by vacuum flashing to obtain a particle size of 85.5 nm small particle size polybutadiene latex emulsion.

[0062] (2) Cool the reactor to 60°C, add 15g of liquid polybutadiene to the reactor (300g of 10%wt butadiene cyclohexane solution is added to the three-necked flask, keep the temperature in a water bath at 50°C for 30min, add the initiator n-Butyllithium, tetrahydrofuran, a structural regulator, until the concentrations of n-butyllithium and tetrahydrofuran in the system are 25mmol / L and 0.25mmol / L respectively, the polymerization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com