Radiation crosslinked polypropylene/montmorillonite composite material preparation method

A technology of cross-linked polypropylene and composite materials is applied in the field of preparation of irradiation cross-linked polypropylene/montmorillonite composite materials, which can solve the problems of unfavorable performance and influence of cross-linked polypropylene, and achieve the effect of preventing oxygen oxidative degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Maleic anhydride grafted polypropylene and organic montmorillonite are extruded and granulated in an extruder at a mass ratio of 1:1 to obtain a maleic anhydride grafted polypropylene / organic montmorillonite masterbatch, and the extruder The temperature is set at 200°C and the screw speed is 150rpm. Take 60g of maleic anhydride grafted polypropylene / organic montmorillonite masterbatch, mix it with 50g of crosslinking agent trimethylolpropane triacrylate and 1000g of polypropylene Extrude and granulate to prepare the polypropylene / organic montmorillonite material to be irradiated, and the working conditions of the extruder are the same as above. The polypropylene / organic montmorillonite material to be irradiated was irradiated with electrons in an air atmosphere, and the irradiation dose was 0.7KGy. The gel content of the composite material after radiation crosslinking was 18% after extraction with xylene.

Embodiment 2

[0023] Maleic anhydride grafted polypropylene and organic montmorillonite are extruded and granulated in an extruder at a mass ratio of 1:1 to obtain a maleic anhydride grafted polypropylene / organic montmorillonite masterbatch, and the extruder The temperature is set at 200°C, the screw speed is 150rpm, take 60g of maleic anhydride grafted polypropylene / organic montmorillonite masterbatch, mix it with 50g of crosslinking agent trimethylolpropane trimethacrylate and 1000g of polypropylene After uniformity, extrude and granulate to obtain the polypropylene / organic montmorillonite material to be irradiated. The working conditions of the extruder are the same as above. The polypropylene / organic montmorillonite material to be irradiated was irradiated with electrons in an air atmosphere, and the irradiation dose was 1.05KGy. The gel content of the composite material after radiation crosslinking was 22% after extraction with xylene.

[0024] comparative example

[0025] 30g of mal...

Embodiment 3

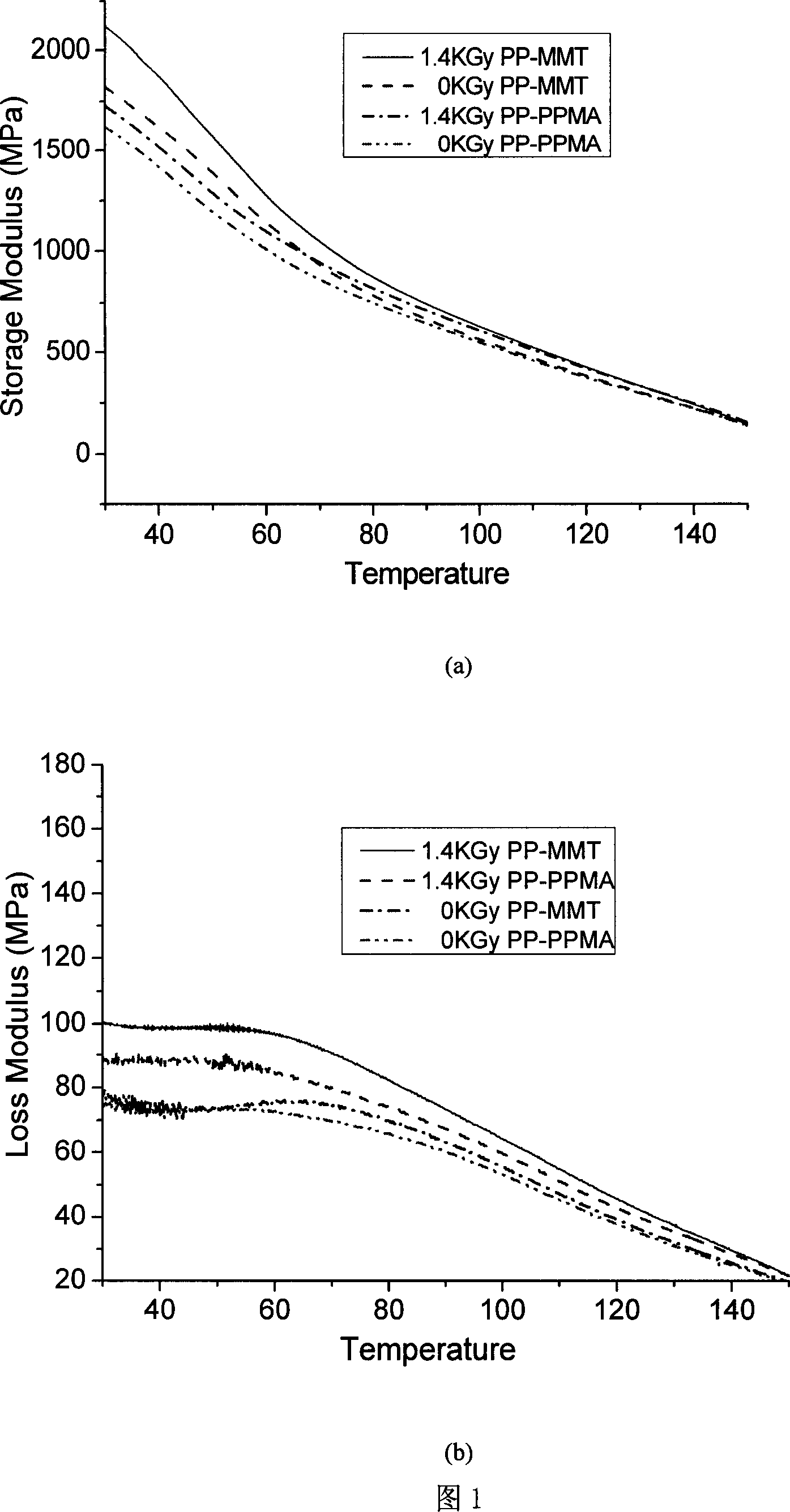

[0027] Get the maleic anhydride grafted polypropylene / organic montmorillonite masterbatch in 100g example 1, mix with 50g cross-linking agent trimethylol propane triacrylate, 1000g polypropylene and extrude granulation, make polypropylene / organic montmorillonite materials to be irradiated, the working conditions of the extruder are the same. The polypropylene / organic montmorillonite material to be irradiated was irradiated with electrons in an air atmosphere, and the irradiation doses were 0.35, 0.7, 1.05, and 1.4KGy, respectively. The gel content of the composite material after irradiation crosslinking was extracted with xylene, and its gel content is listed in Table 1; the composite material irradiated and unirradiated at 1.4KGy was used for dynamic mechanical testing, as shown in Figure 1. PP-MMT refers to composite materials containing montmorillonite.

[0028] comparative example

[0029] 50g of maleic anhydride grafted polypropylene was mixed with 50g of crosslinking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com