Palygorskite silane crosslinking agent preparation method and application of palygorskite silane crosslinking agent in low-density polyethylene crosslinking

A technology of silane crosslinking agent and silane, which is applied in the field of palygorskite clay crosslinking agent and its preparation, can solve the problems of unreported application and market circulation, so as to improve mechanical properties and gel content, reduce cost, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

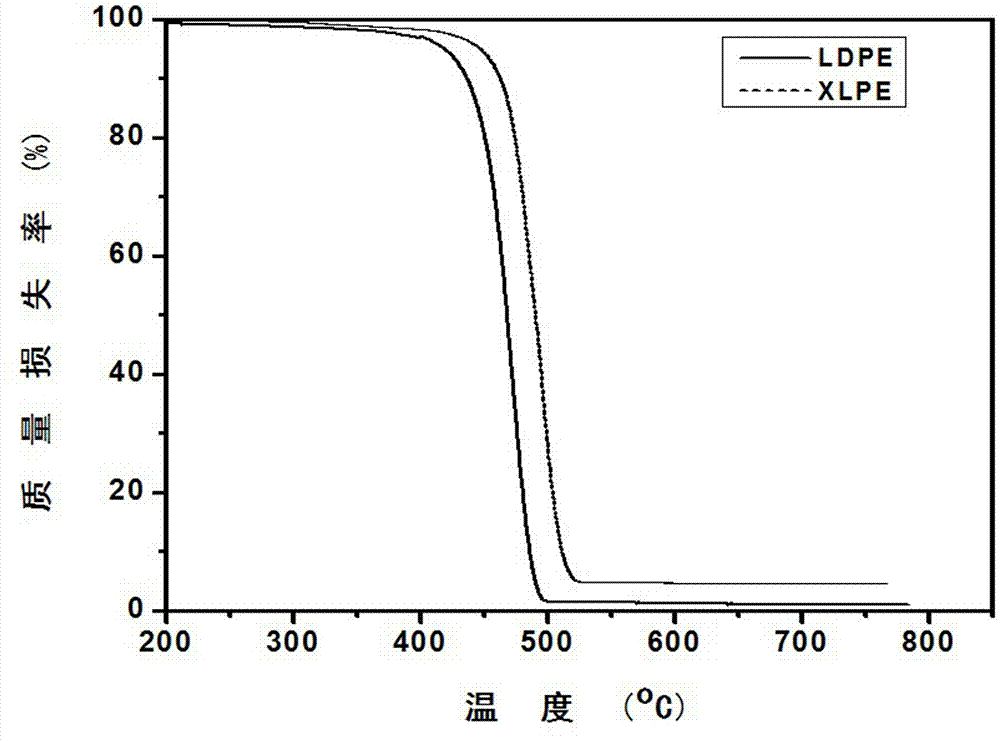

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

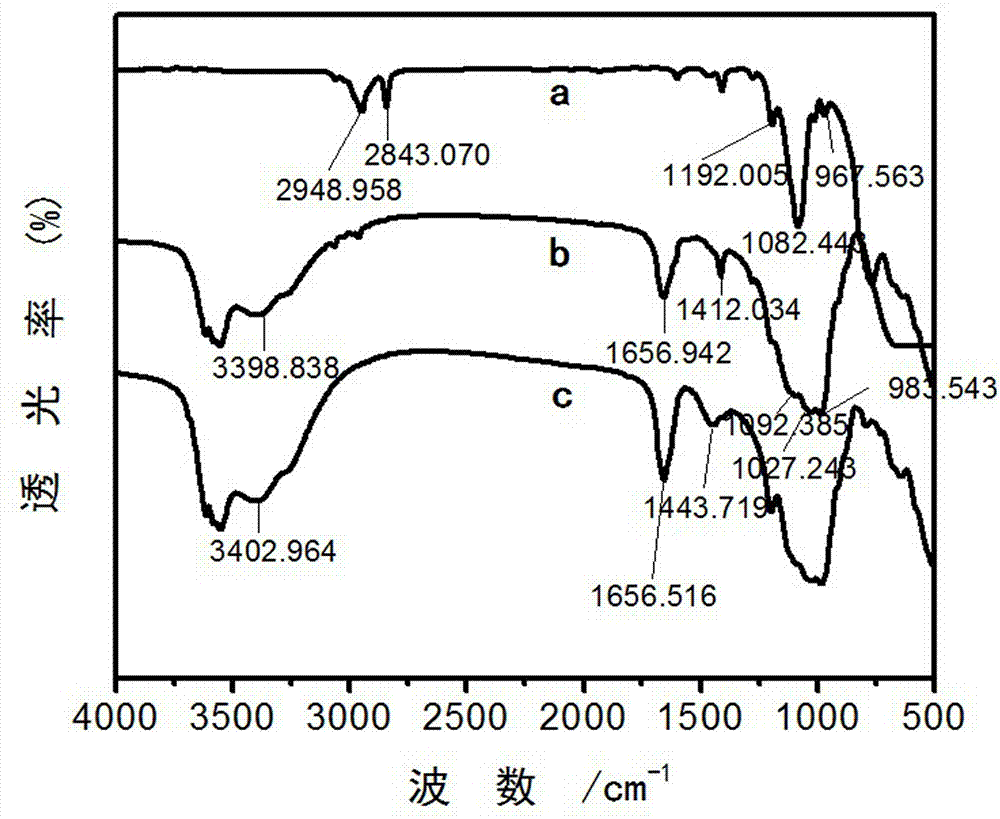

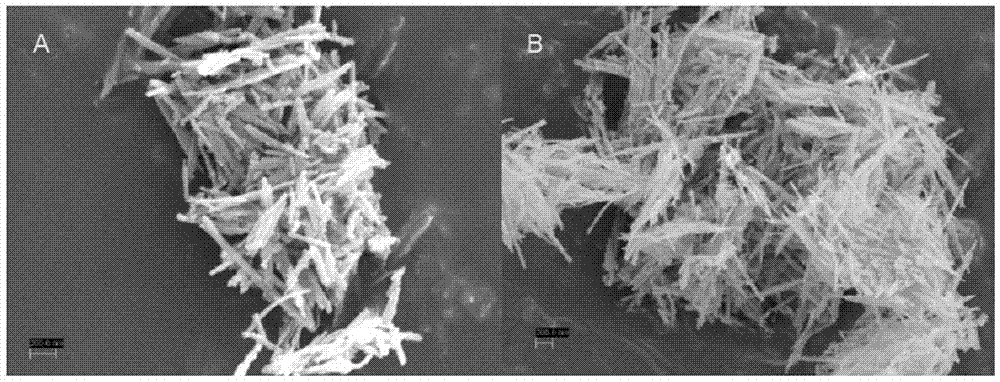

[0034] 1. Preparation of palygorskite silane crosslinking agent

[0035] (1) Acid treatment of silane cross-linking agent: Add 1 mL of silane cross-linking agent to 5 mL of absolute ethanol, then adjust the pH to 3-3.5 with glacial acetic acid, and stir at room temperature for 1 h.

[0036] (2) Activation of palygorskite: Add 100g of palygorskite clay into 250mL NaOH solution with a mass fraction of 5%, stir magnetically at 45°C for 12h, then rinse the neutral with distilled water, centrifuge, and take the filter cake to dry, namely The activated palygorskite was obtained and ground for use.

[0037] (3) Preparation of palygorskite silane crosslinking agent:

[0038] Disperse 1 g of activated palygorskite in 10 mL of ethanol / water mixture (15 mL of ethanol, 1 mL of water), ultrasonically disperse for 15 min, and then add the above-mentioned treated silane crosslinking agent dropwise (wherein the net content of silane crosslinking agent is 0.005 g), add a certain amount of de...

Embodiment 2

[0043]1. Preparation of palygorskite silane crosslinking agent

[0044] (1) Acid treatment of silane cross-linking agent: Add 1 mL of silane cross-linking agent to 15 mL of absolute ethanol, then adjust the pH to 3-3.5 with glacial acetic acid, and stir at room temperature for 0.2 h.

[0045] (2) Activation of palygorskite: Add 100g of palygorskite clay into 250mL NaOH solution with a mass fraction of 10%, stir magnetically at 65°C for 48h, then rinse the neutral with distilled water, centrifuge, and take the filter cake to dry, namely The activated palygorskite was obtained and ground for use.

[0046] (3) Preparation of palygorskite silane crosslinking agent:

[0047] Disperse 1 g of activated palygorskite in 25 mL of ethanol / water mixture (25 mL of ethanol, 1 mL of water), ultrasonically disperse for 40 min, and then add the above-mentioned treated silane crosslinking agent dropwise (the net content of silane crosslinking agent is 0.05 g), add a certain amount of deionize...

Embodiment 3

[0052] 1. Preparation of palygorskite silane crosslinking agent

[0053] (1) Acid treatment of silane cross-linking agent: Add 1 mL of silane cross-linking agent to 10 mL of absolute ethanol, then adjust the pH to 3-3.5 with glacial acetic acid, and stir at room temperature for 0.5 h.

[0054] (2) Activation of palygorskite: Add 100g of palygorskite clay into 250mL NaOH solution with a mass fraction of 8%, stir magnetically at 55°C for 36h, then rinse the neutral with distilled water, centrifuge, and take the filter cake to dry, that is The activated palygorskite was obtained and ground for use.

[0055] (3) Preparation of palygorskite silane crosslinking agent:

[0056] Disperse 1 g of activated palygorskite in 20 mL of ethanol / water mixture (20 mL of ethanol, 1 mL of water), ultrasonically disperse for 35 min, and then add the above-mentioned treated silane crosslinking agent dropwise (the net content of silane crosslinking agent is 0.01 g), add a certain amount of deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com