High pressure resistance irradiation crosslinking environment-friendly and flame-retardant rubber and plastic composite material and preparation method thereof

A composite material and high-pressure-resistant technology, which is applied in the field of high-voltage-resistant radiation cross-linked environmentally friendly flame-retardant rubber-plastic composite materials and its preparation, can solve problems such as inability to meet high-temperature welding, inconsistent overall performance and use occasions, and achieve excellent Abrasion resistance, effect of high gel content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

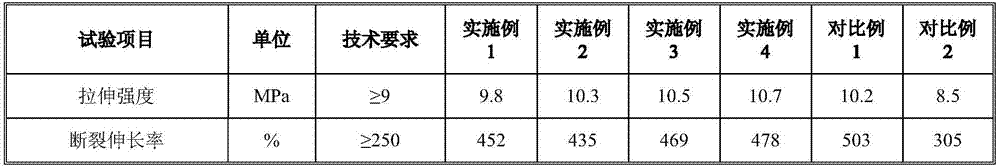

Embodiment 1

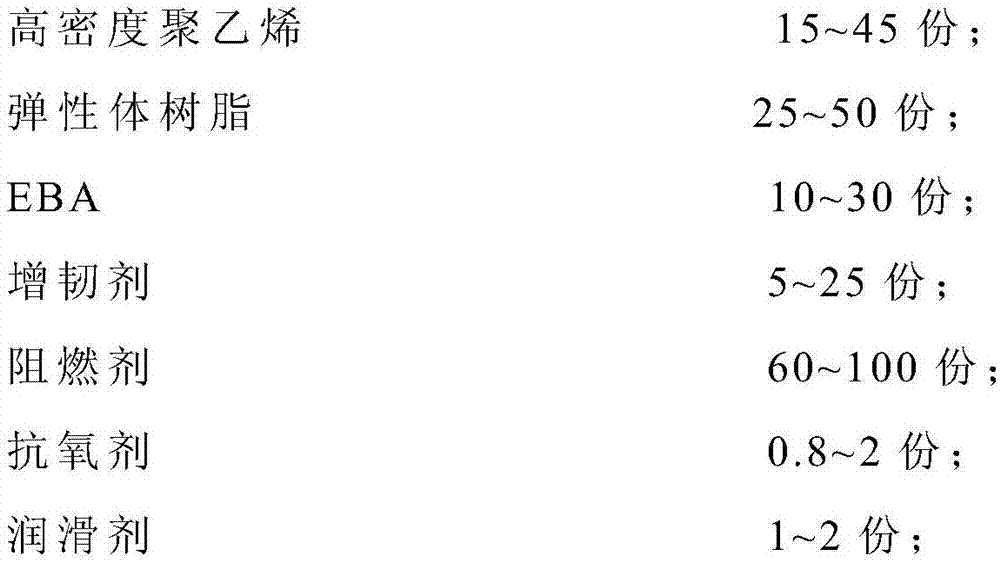

[0034] This example provides a high-voltage radiation-resistant cross-linked environmentally friendly flame-retardant rubber-plastic composite material. The raw materials and dosages used are shown in Table 1, wherein:

[0035] High-density polyethylene: high-density polyethylene with a melt index of 0.9g / 10min (derived from Daqing Petroleum Company, grade 5000s) and high-density polyethylene with a melt index of 7.5g / 10min (derived from Dushanzi Petrochemical Company, The grade is 6070) according to the mass ratio of 1:0.5 composition.

[0036] Elastomer resin: It is composed of polyurethane elastomer (derived from BASF) and EPDM elastomer (derived from Dow) at a mass ratio of 1:1, wherein the ethylene content in EPDM elastomer 75%.

[0037] EBA: choose EBA with BA content of 17% and melt index of 7g / 10min.

[0038] Toughening agent: a maleic anhydride grafted ethylene-octene copolymer (derived from DuPont) with a melt index of 1g / 10min and a linear low density polyethylene...

Embodiment 2

[0048] This example provides a high-voltage radiation-resistant cross-linked environmentally friendly flame-retardant rubber-plastic composite material. The raw materials and dosages used are shown in Table 1. The raw materials other than the following are the same as those in Example 1.

[0049] High-density polyethylene: It is composed of high-density polyethylene with a melt index of 0.3g / 10min and high-density polyethylene with a melt index of 20g / 10min in a mass ratio of 1.5:0.5.

[0050] Elastomer resin: It is composed of polyurethane elastomer and EPDM elastomer in a mass ratio of 3:4, wherein the ethylene content in the EPDM elastomer is 70%.

[0051]EBA: choose EBA with BA content of 28% and melt index of 15g / 10min.

[0052] Toughening agent: composed of maleic anhydride grafted ethylene-octene copolymer with a melt index of 1.2g / 10min and maleic anhydride grafted linear low density polyethylene with a melt index of 1.5g / 10min in a mass ratio of 1:1 .

[0053] Antio...

Embodiment 3

[0057] This example provides a high-voltage radiation-resistant cross-linked environmentally friendly flame-retardant rubber-plastic composite material. The raw materials and dosages used are shown in Table 1. The raw materials other than the following are the same as those in Example 1.

[0058] High-density polyethylene: It is composed of high-density polyethylene with a melt index of 2g / 10min and high-density polyethylene with a melt index of 15g / 10min in a mass ratio of 1:0.5.

[0059] Elastomer resin: It is composed of polyurethane elastomer and EPDM elastomer in a mass ratio of 3:5, wherein the ethylene content in the EPDM elastomer is 65%.

[0060] The preparation process of the composite material is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com