Cable insulation material of wearproof modified phenolic resin

A phenolic resin and cable insulation technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve the problem that conventional cables cannot meet the requirements of wear resistance, and achieve convenient and effortless cutting, chemical corrosion resistance improvement, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

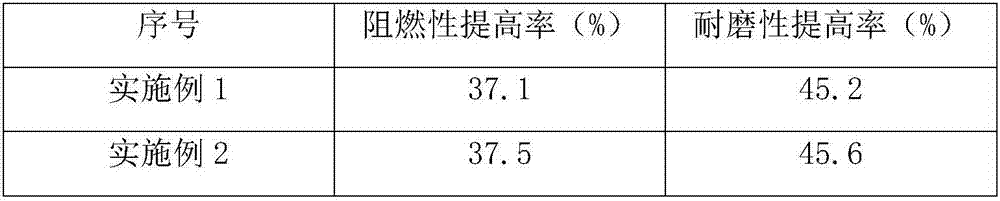

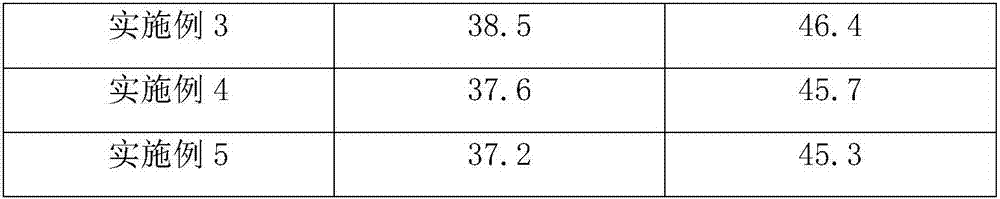

Embodiment 1

[0018] The invention provides a cable insulation material of wear-resistant modified phenolic resin, which is composed of the following components by weight: 32 parts of polyvinyl chloride, 30 parts of modified phenolic resin, 11 parts of silicone rubber, and 4 parts of ethylene-vinyl acetate copolymer 2 parts, 2 parts of ethylene acrylic acid grafted maleic anhydride, 3 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, 1 part of sodium stearate, 5 parts of aramid short fiber, 6 parts of montmorillonite, 2 parts of paraffin, 4 parts of nano-polyacrylate modified magnesium hydroxide, 2 parts of nano-calcium carbonate powder, 3 parts of nano-boron nitride, 1 part of microcrystalline cellulose, 2 parts of silane coupling agent, 4 parts of wear-resistant powder, 5 parts of talc powder , 2 parts of zinc oxide whiskers, 1 part of graphene, 1 part of fullerene, 3 parts of antioxidant, 5 parts of flame retardant, and 6 parts of filler fine material.

[0019] As a pre...

Embodiment 2

[0026] The invention provides a cable insulation material of wear-resistant modified phenolic resin, which is composed of the following components by weight: 33 parts of polyvinyl chloride, 31 parts of modified phenolic resin, 12 parts of silicone rubber, and 5 parts of ethylene-vinyl acetate copolymer 3 parts, 3 parts of ethylene acrylic acid grafted maleic anhydride, 4 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, 2 parts of sodium stearate, 6 parts of aramid short fiber, 7 parts of montmorillonite, 3 parts of paraffin, 5 parts of nano polyacrylate modified magnesium hydroxide, 3 parts of nano calcium carbonate powder, 4 parts of nano boron nitride, 2 parts of microcrystalline cellulose, 3 parts of silane coupling agent, 5 parts of wear-resistant powder, 6 parts of talcum powder , 3 parts of zinc oxide whisker, 2 parts of graphene, 2 parts of fullerene, 4 parts of antioxidant, 6 parts of flame retardant, 7 parts of filler fine material.

[0027] As a pr...

Embodiment 3

[0034]The invention provides a cable insulation material of wear-resistant modified phenolic resin, which is composed of the following components by weight: 34 parts of polyvinyl chloride, 32 parts of modified phenolic resin, 13 parts of silicone rubber, and 6 parts of ethylene-vinyl acetate copolymer 4 parts, 4 parts of ethylene acrylic acid grafted maleic anhydride, 5 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, 3 parts of sodium stearate, 7 parts of aramid short fiber, 8 parts of montmorillonite, 4 parts of paraffin wax, 6 parts of nano polyacrylate modified magnesium hydroxide, 4 parts of nano calcium carbonate powder, 5 parts of nano boron nitride, 3 parts of microcrystalline cellulose, 4 parts of silane coupling agent, 6 parts of wear-resistant powder, 7 parts of talcum powder , 4 parts of zinc oxide whisker, 3 parts of graphene, 3 parts of fullerene, 5 parts of antioxidant, 7 parts of flame retardant, and 8 parts of filler fine material.

[0035] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com