Preparation method of cyclohexene oxide

A technology of epoxycyclohexane and cyclohexene, which is applied in the direction of organic chemistry, can solve the problems of high cost and difficulty in recycling catalysts, and achieve the effects of easy recycling, reduced reaction energy consumption, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

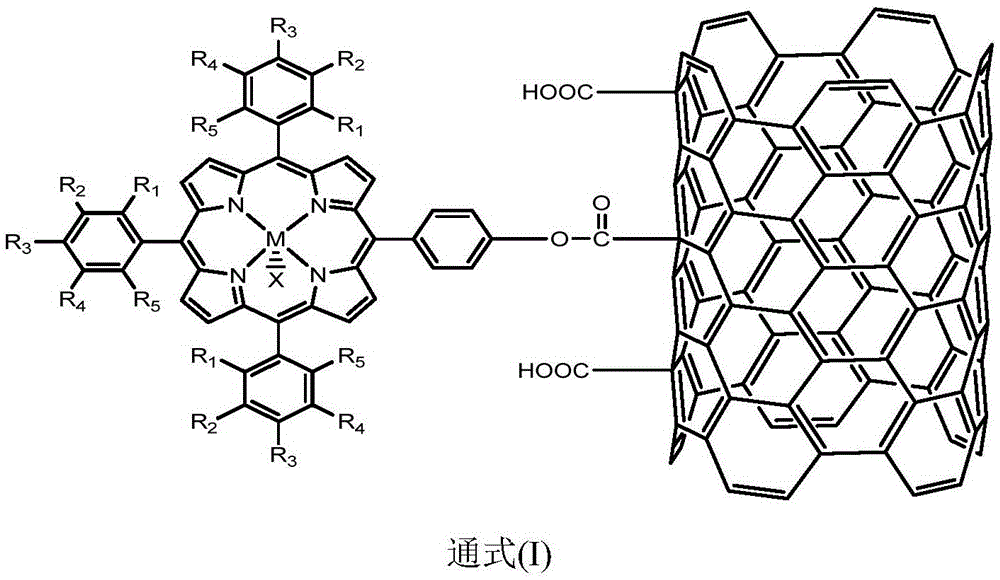

Image

Examples

Embodiment 1

[0018] In 25mL reactor, add 10mL1,2-dichloroethane solvent, 2.5mmol cyclohexene, 0.75mg catalyst (M=Mn in general formula (I), R 1 = R 2 = R 3 = R 4 = R 5 =H, X=Cl), feed 0.1MPa of oxygen, react at a temperature of 20°C for 2 hours, and detect by gas chromatography, the conversion rate of cyclohexene is 94%, and the selectivity of epoxycyclohexane is 99%.

Embodiment 2

[0020] In 25mL reactor, add 10mL acetonitrile solvent, 2.5mmol cyclohexene, 0.075mg catalyst (M=Fe in general formula (I), R 1 = NO 2 , R 2 = R 3 = R 4 = R 5 =H, X=Cl), feed 1.0MPa of oxygen, react at a temperature of 60°C for 2 hours, and detect by gas chromatography, the conversion rate of cyclohexene is 92%, and the selectivity of epoxycyclohexane is 91%.

Embodiment 3

[0022] In 25mL reactor, add 10mL THF solvent, 2.5mmol cyclohexene, 0.15mg catalyst (M=Cu in general formula (I), R 1 = R 5 =Cl,R 2 = R 3 = R 4 =H, X=imidazole), feed 0.1MPa of oxygen, react at a temperature of 25°C for 2 hours, and detect by gas chromatography, the conversion rate of cyclohexene is 98%, and the selectivity of epoxy cyclohexane is 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com