Methyl ethylene carbonic ester block copolymer and preparation method thereof

A technology of methyl ethylene carbonate and block copolymer, applied in the field of polymer materials, can solve problems such as poor mechanical properties and thermal properties, and achieve the effects of high thermal stability, low equipment requirements, and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

[0048] The preparation method of methyl ethylene carbonate-cyclohexylene carbonate diblock copolymer (PPC-PCHC):

[0049] Put 1.0 g of loaded zinc dicarboxylate in an autoclave, and dry it under vacuum at 80°C for 24 hours, then cool the autoclave to room temperature, and quickly inhale 100 ml of PO under vacuum. Then filled with CO 2 , stirred at a speed of 100 rpm, heated to 60° C., adjusted to 5.2 MPa in the kettle, and reacted for 12 hours. Then the reactor was cooled rapidly under an ice bath to release carbon dioxide. After vacuuming, quickly inhaled CHO and introduced CO 2 , stirred at a speed of 100rpm, heated to 80°C, adjusted the pressure in the kettle to 5.0-5.2MPa, reacted for 12 hours, cooled to room temperature, released carbon dioxide, and took out the viscous mixture in the kettle. The product was dissolved in chloroform, and the catalyst in the system was removed with 5 wt% dilute hydrochloric acid solution, and washed three times with distilled water. Then...

Embodiment 11-18

[0054] The preparation method of cyclohexylene carbonate-methylethylene carbonate-cyclohexylene carbonate triblock copolymer (PCHC-PPC-PCHC):

[0055] Put 1.0 g of loaded zinc dicarboxylate in the autoclave, and dry it under vacuum at 80°C for 24 hours, then cool the autoclave to room temperature, quickly inhale CHO under vacuum, and pass in CO 2 , stirred at a speed of 100rpm, heated to 80°C, and adjusted the pressure inside the kettle to 5.2MPa. After 12 hours of reaction, the reaction kettle was rapidly cooled in an ice bath to release carbon dioxide, and 100ml PO was quickly inhaled under vacuum. Then filled with CO 2 , stirred at a speed of 100rpm, heated to 60°C, and adjusted the pressure inside the kettle to 5.2MPa. After 12 hours of reaction, the reactor was rapidly cooled in an ice bath to release carbon dioxide, quickly inhaled CHO under vacuum, and introduced CO 2 , stirred at a speed of 100rpm, heated to 80°C, adjusted the pressure inside the kettle to 5.2MPa, rea...

Embodiment 19-24

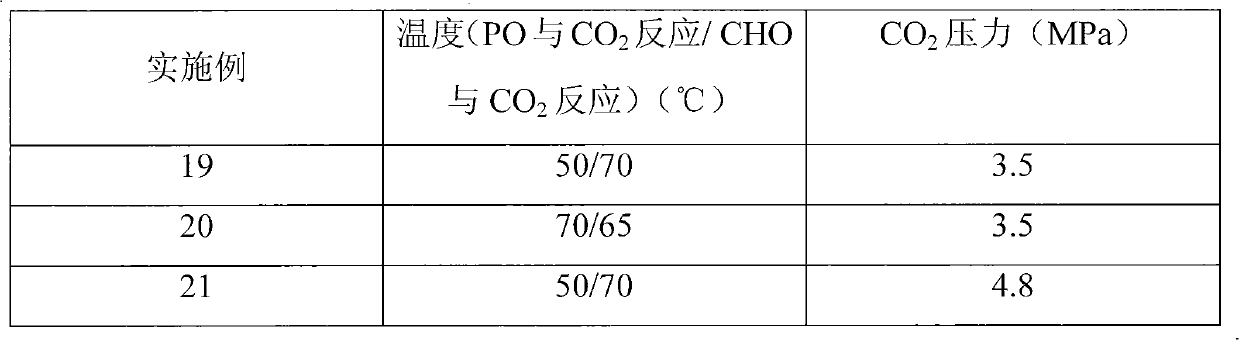

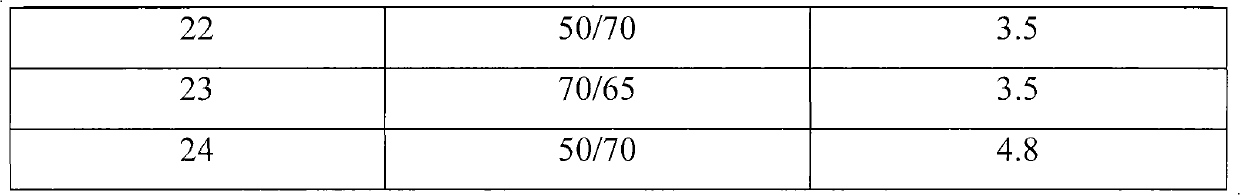

[0061] different temperature and CO 2 Methylethylene carbonate-cyclohexylene carbonate diblock copolymer under pressure (PPC-PCHC), cyclohexylene carbonate-methylethylene carbonate-cyclohexylene carbonate triblock copolymer (PCHC -PPC-PCHC) preparation:

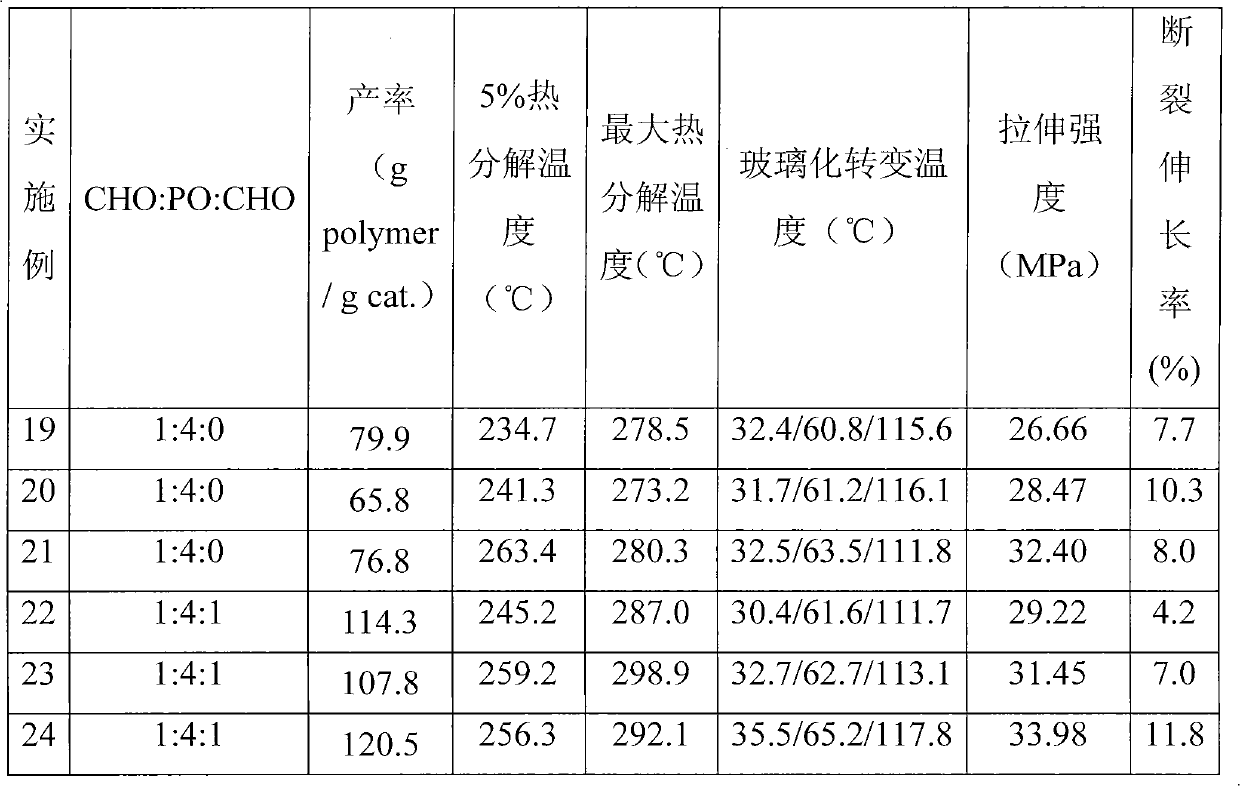

[0062] According to the preparation method of the above-mentioned examples 1-10, 11-18, adjust PO, CHO monomer and CO 2 The reaction temperature and pressure, as shown in table 3, carry out methyl ethylene carbonate-cyclohexylene carbonate diblock copolymer (PPC-PCHC), cyclohexylene carbonate-methyl ethylene carbonate-ring The preparation of hexylene carbonate triblock copolymer (PCHC-PPC-PCHC) is shown in Examples 19-24. At the same time, the block copolymers prepared in Examples 19-24 were placed in a flat vulcanizer and pressed for 3 minutes at 170°C for direct molding; the resulting block polymers were cut into standard strips of 25mm×1mm×4mm for The performance test results are shown in Table 4.

[0063] Table 3 prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com