Hierarchical-pore titanium silicon molecular sieve catalyst synthesized with assistance of aerosol and preparation method of hierarchical-pore titanium silicon molecular sieve catalyst

An aerosol, multi-level pore technology, applied in molecular sieve catalysts, hydroxyl addition preparation, chemical instruments and methods, etc., to achieve the effects of mild conditions, high activity and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

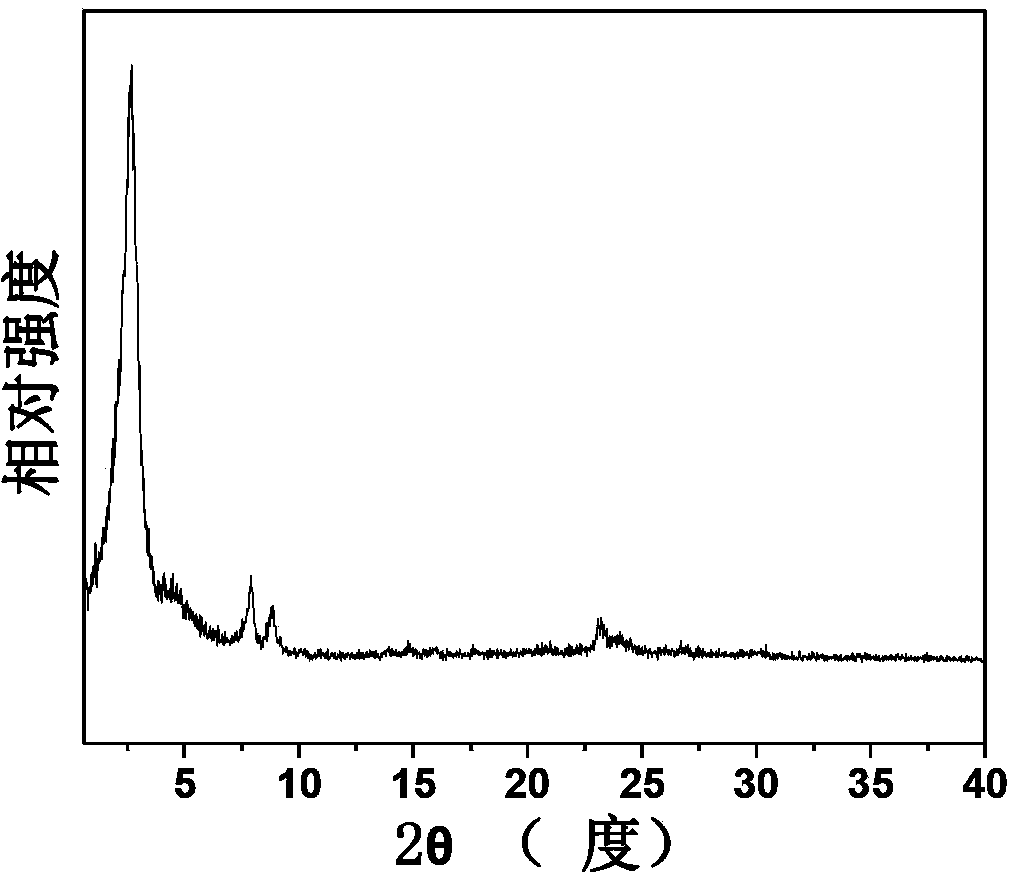

Embodiment 1

[0027] (1) Mix the TPAOH solution with the silicon source, stir at 30°C for 6h, and at the same time mix the titanium source with the TPAOH solution, stir at 20°C for 3h, the molar ratio of each raw material after the two are mixed is: SiO 2 : TiO 2 :TPAOH:H 2 O=1:0.033:0.2:60, mix and distill alcohol for 2 hours, then put in a kettle and crystallize at 170°C for 4 hours.

[0028] (2) After cooling, the solid obtained by centrifuging the above solution is dispersed in the ethanol solution of CTAB, and a certain amount of silicon source is added dropwise. Stir for 3 hours to mix evenly, form an aerosol with air with a pressure of 10si through an aerosol generator, dry it through a quartz tube at 350°C to obtain a solid, dry it in an air atmosphere, and remove the template agent by roasting to obtain a hierarchical porous titanium-silicon molecular sieve product.

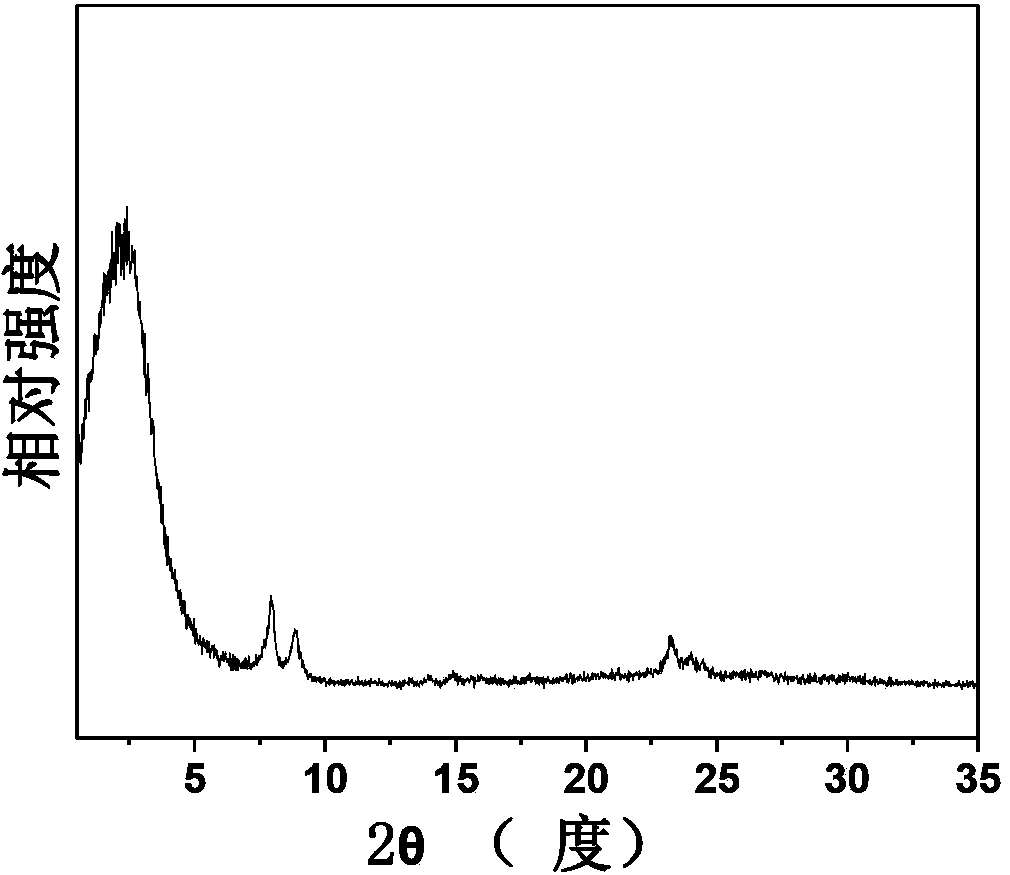

Embodiment 2

[0030] (1) Mix the TPAOH solution with the silicon source, stir at 30°C for 6h, and at the same time mix the titanium source with the TPAOH solution, stir at 20°C for 3h, the molar ratio of each raw material after the two are mixed is: SiO 2 : TiO 2 :TPAOH:H 2 O=1:0.033:0.2:60, mixed for 2 hours, distilled alcohol, put in a kettle and crystallized at 170°C for 4 hours.

[0031] (2) After cooling, add 50ml CTAB ethanol solution dropwise to the above solution, and add silicon source and titanium source: SiO 2 / TiO 2 =30. Stir for 3 hours to mix evenly, form an aerosol with air with a pressure of 10si through an aerosol generator, dry it through a quartz tube at 350°C to obtain a solid, dry it in an air atmosphere, and remove the template agent by roasting to obtain a hierarchical porous titanium-silicon molecular sieve product.

Embodiment 3

[0033] (1) Mix the TPAOH solution with the silicon source, stir at 30°C for 6h, and at the same time mix the titanium source with the TPAOH solution, stir at 20°C for 3h, the molar ratio of each raw material after the two are mixed is: SiO 2 : TiO 2 :TPAOH:H 2 O=1:0.33:0.2:60, mix for 2 hours, distill the alcohol, put in a kettle and crystallize at 170°C for 4 hours.

[0034] (2) After cooling, add 50ml CTAB ethanol solution dropwise to the above solution, and add silicon source and titanium source: SiO 2 / TiO 2 =60. Stir for 3 hours to mix evenly, form an aerosol with air with a pressure of 10si through an aerosol generator, dry it through a quartz tube at 350°C to obtain a solid, dry it in an air atmosphere, and remove the template agent by roasting to obtain a hierarchical porous titanium-silicon molecular sieve product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com