Polyimide fiber with kidney-shaped section and preparation method thereof

A polyimide fiber, polyimide technology, applied in fiber treatment, spinning solution preparation, fiber chemical characteristics, etc. The production cost is low, the cohesion is strong, and the preparation efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

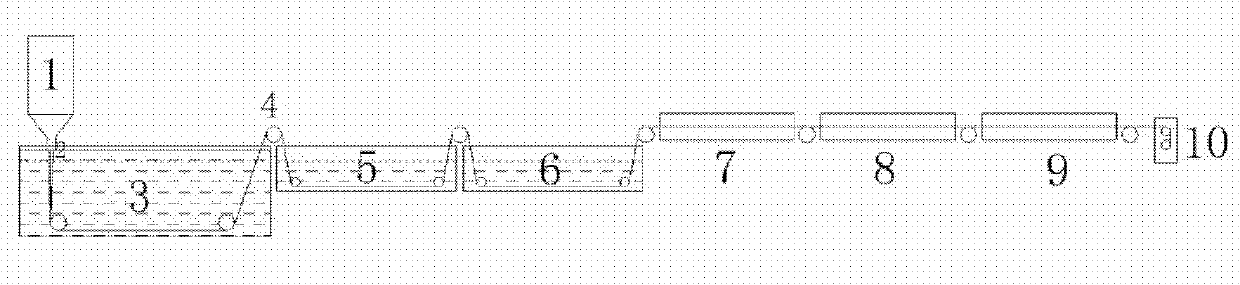

[0034] A: Use low-cost PMDA and ODA to synthesize a PAA solution with a solid content of 15%. After filtering and vacuuming to remove air bubbles, spin through a wet process;

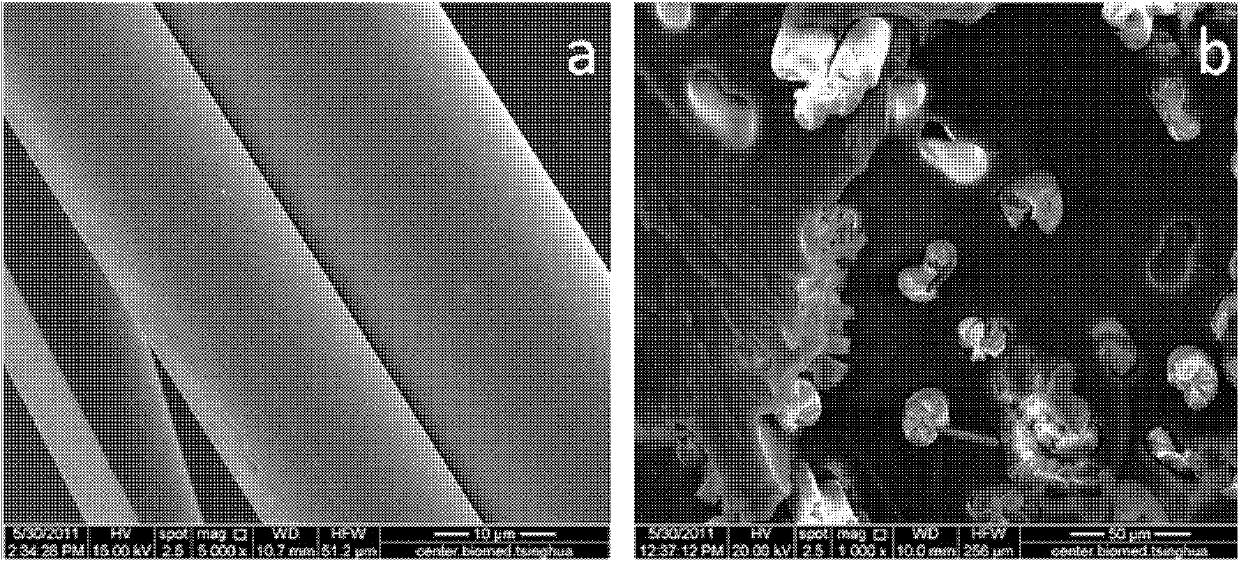

[0035] B: The fibers ejected from the circular spinneret hole directly enter the coagulation bath solution using pure water at a temperature of 25°C. Four coagulation baths are used, and the spinning speed is adjusted by changing the speed of the metering pump. The spinning speed is set separately. Determined as 15, 20 or 25m / min, the length of the vertical hydrazine depth is 100mm, and PAA primary fibers with kidney-shaped cross section can be prepared;

[0036] C: The PAA primary fiber obtained in step B is directly washed to remove the solvent, the washing temperature range is 20-80°C, heated and dried at 80°C to remove water, and then subjected to step-wise high-temperature circular drawing, the temperature range is 160-400°C , high-temperature annealing at 500 °C in a nitrogen atmosphere, and final...

Embodiment 2

[0039]A: Use low-cost PMDA and ODA to synthesize a PAA solution with a solid content of 20%. After filtering and vacuuming to remove air bubbles, spin by wet method;

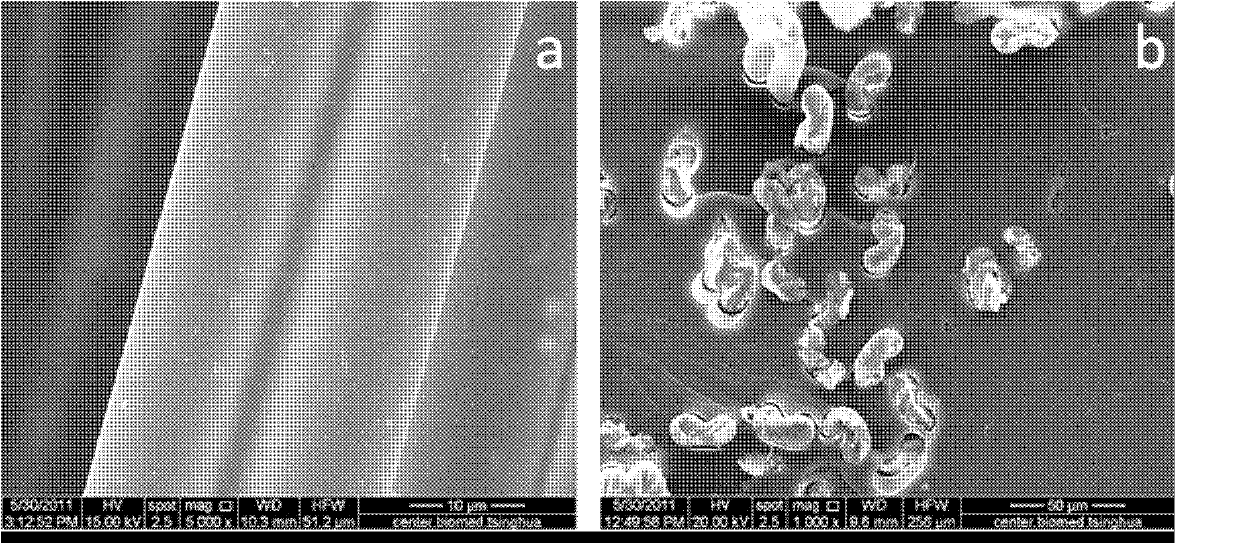

[0040] B: The fibers ejected from the circular spinneret hole directly enter the coagulation bath solution with pure water and different temperatures. A coagulation bath is used, and the temperature of the coagulation bath is set at 10, 25 or 40 ° C. By changing the speed of the metering pump Regulating spinneret speed, spinning speed is 20m / min, and the length of vertical hydrazine deep is 50mm, prepares the PAA nascent fiber with kidney-shaped cross section;

[0041] C: The PAA primary fiber obtained in step B is directly washed to remove the solvent, the washing temperature range is 40-80°C, heated and dried at 100°C to remove water, and high-temperature cyclization is drawn, the temperature range is 160-450°C, and the temperature range is 160-450°C. High-temperature annealing in a nitrogen atmosphere at ℃, a...

Embodiment 3

[0044] A: Use low-cost PMDA and ODA to synthesize a PAA solution with a solid content of 25%. After filtering and vacuuming to remove air bubbles, spin by wet method;

[0045] B: The fibers ejected from the circular spinneret hole directly enter the coagulation bath solution with a temperature of 30°C and different coagulation bath systems. Five coagulation baths are used, and the coagulation bath system is water / ethanol, water / DMAc or water / ethylene glycol. Alcohol system, adjust the spinning speed by changing the metering pump speed, the spinning speed is 10m / min, the length of the vertical hydrazine depth is 50mm, and the PAA primary fiber with kidney-shaped cross section is prepared;

[0046] C: The PAA primary fiber obtained in step B is directly washed to remove the solvent, the washing temperature range is 30-95°C, heated and dried at 120°C to remove water, high-temperature circular drawing, the temperature range is 150-480°C, and the temperature range is 150-480°C. Hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com