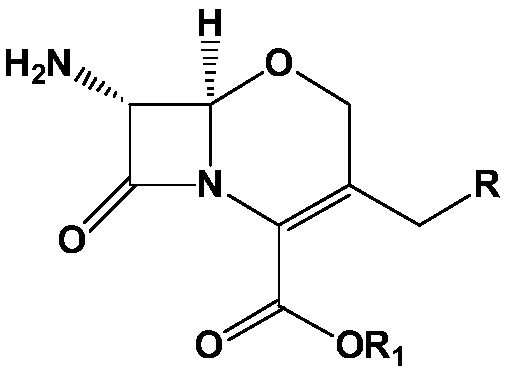

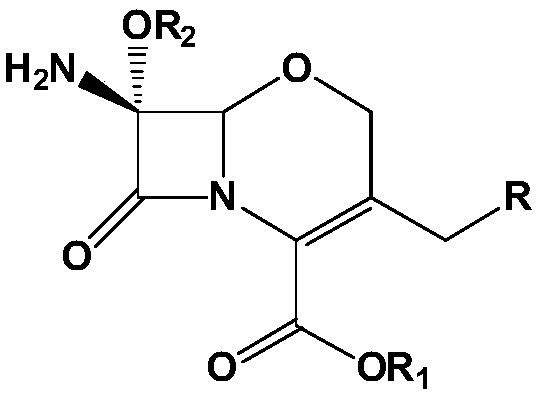

METHOD FOR MANUFACTURING 7alpha-ALKOXYOXACEPHEM INTERMEDIATE COMPOUND

A technology for alkoxy cephem and intermediates, which is applied in the field of preparation of 7α-alkoxy cephem intermediates, can solve problems such as unfavorable, expensive photoreaction equipment, low yield and the like, and achieves easy mass production , excellent yield, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

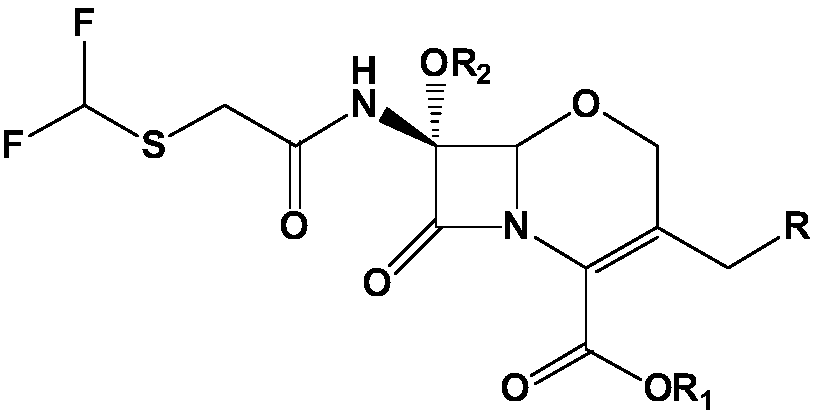

[0084] Example 1. (6R,7R)-diphenylmethyl-7-(difluoromethylthio)acetamido)-3-(chloromethyl)-7-methoxy-8-oxo-5 Preparation of oxa-1-aza-bicyclo[4,2,0]oct-2-ene-2-carboxylate

[0085] As starting material, 50.0 g (0.13 mol) of 7-amino-3-chloromethyl-1-oxa-3-cephem-4-carboxylic acid diphenyl ester were injected with 450 g of dichloromethane, and After cooling to -20°C, 29.0 g (0.4 moles) of chlorine was injected for 60 minutes. After stirring for 10 minutes at the same temperature, 174.7 g (0.46 mol) of a methanol solution of 10% LiOMe (lithium methoxy) was dropped at a temperature of -40°C to -50°C. Then, after stirring for 5 minutes at the same temperature, 6.4 g (0.11 mol) of acetic acid was added. 428.5 g of 10% sodium sulfite and 400 g of purified water were sequentially added to the above reaction solution. After stirring for 30 minutes, the dichloromethane layer was separated and washed with dilute sodium bicarbonate. After adding 50 g of anhydrous magnesium sulfate to ...

Embodiment 2

[0089] Example 2. (6R,7R)-diphenylmethyl-7-amino-7-methoxy-3-((1-methyl-1H-tetrazol-5-ylthio)methyl)-8 - Preparation of oxo-5-oxa-1-aza-bicyclo[4.2.0]oct-2-ene-2-carboxylate

[0090] As starting material, 50.0 g (0.13 mol) of 7-amino-3-chloromethyl-1-oxa-3-cephem-4-carboxylic acid diphenyl ester were injected with 450 g of dichloromethane, and After cooling to -20°C, 29.0 g (0.4 moles) of chlorine was injected for 60 minutes. After stirring for 10 minutes at the same temperature, 174.7 g (0.46 mol) of a methanol solution of 10% LiOMe (lithium methoxy) was dropped at a temperature of -40°C to -50°C. Then, after stirring for 5 minutes at the same temperature, 6.4 g (0.11 mol) of acetic acid was added. 428.5 g of 10% sodium sulfite and 400 g of purified water were sequentially added to the above reaction solution. After stirring for 30 minutes, the dichloromethane layer was separated and washed with dilute sodium bicarbonate. After adding 50 g of anhydrous magnesium sulfate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com