Anionic-nonionic composite efficient flushing fluid and preparation method thereof

A non-ionic, flushing liquid technology, applied in chemical instruments and methods, drilling compositions, etc., to achieve good flushing efficiency, good compatibility, and the effect of promoting flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

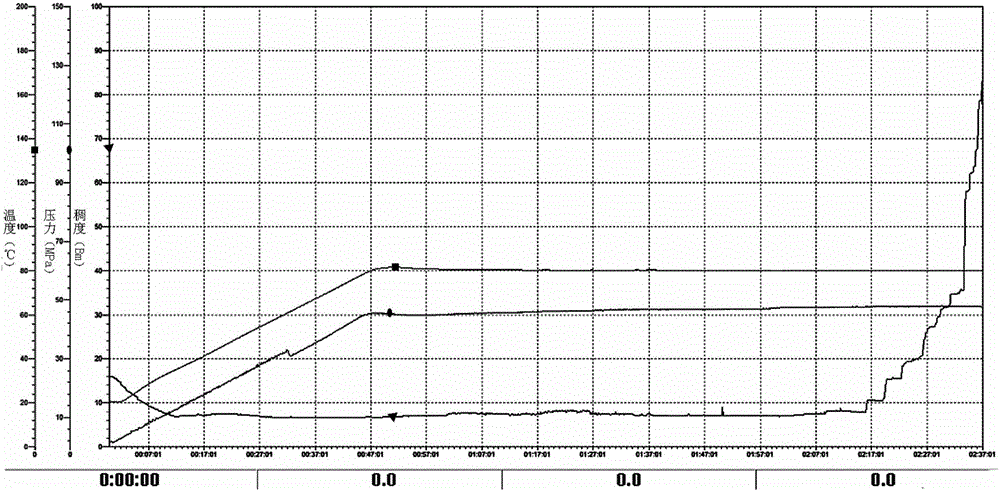

Embodiment 1

[0027] [Example 1] Anion-nonionic composite high-efficiency flushing solution, which is prepared from the following raw materials in mass percentage:

[0028]

[0029] The anion-nonionic composite high-efficiency flushing fluid also includes 0.5 g of a silicon ether copolymerized defoamer.

[0030] The preparation method of anion-nonionic composite high-efficiency flushing liquid, it comprises the following steps:

[0031] S1. Weigh the required mass percentage of raw materials, and heat the required water to 45°C;

[0032] S2. Add sodium tripolyphosphate and stir at 800 rpm for 20 minutes to fully dissolve it;

[0033] S3. Add polyoxyethylene sorbitan fatty acid ester, fatty alcohol polyoxyethylene ether sodium sulfate and nonylphenol polyoxyethylene ether to the solution obtained in step S2 and stir at 800 rpm for 80 minutes, and finally prepare Add silicon ether copolymerization defoamer to the solution and stir evenly. The prepared rinsing solution was mixed with wat...

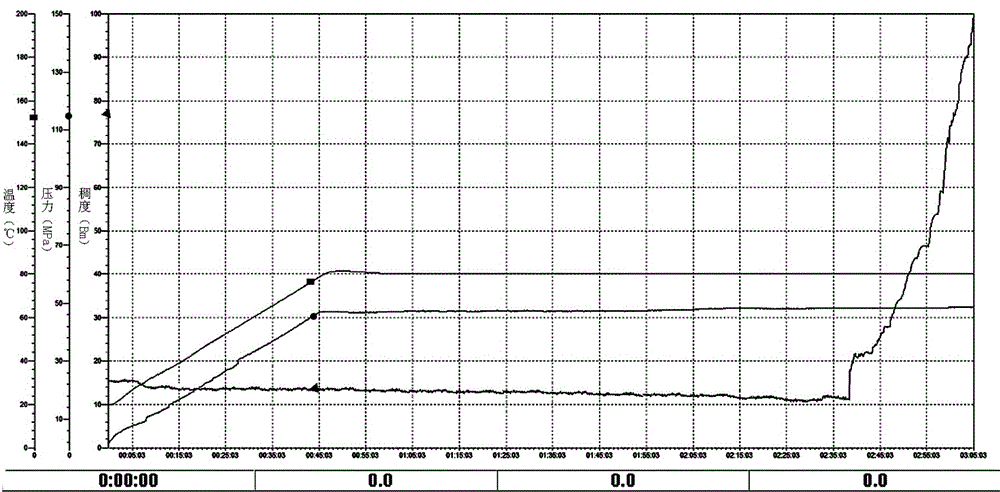

Embodiment 2

[0034] [Example 2] Anion-nonionic composite high-efficiency flushing solution, which is prepared from the following raw materials in mass percentage:

[0035]

[0036] The anion-nonionic composite high-efficiency flushing fluid also includes 0.8 g of a silicone ether copolymerized defoamer.

[0037] The preparation method of anion-nonionic composite high-efficiency flushing liquid, it comprises the following steps:

[0038] S1. Weigh the required mass percentage of raw materials, and heat the required water to 50°C;

[0039] S2. Add sodium tripolyphosphate and stir at 1000 rpm for 25 minutes to fully dissolve it;

[0040] S3. Add polyoxyethylene sorbitan fatty acid ester, fatty alcohol polyoxyethylene ether sodium sulfate and nonylphenol polyoxyethylene ether to the solution obtained in step S2 and stir for 100 minutes at 1000 rpm, and finally prepare Add silicon ether copolymerized antifoaming agent into the solution and stir evenly, and prepare the rinse solution into 1...

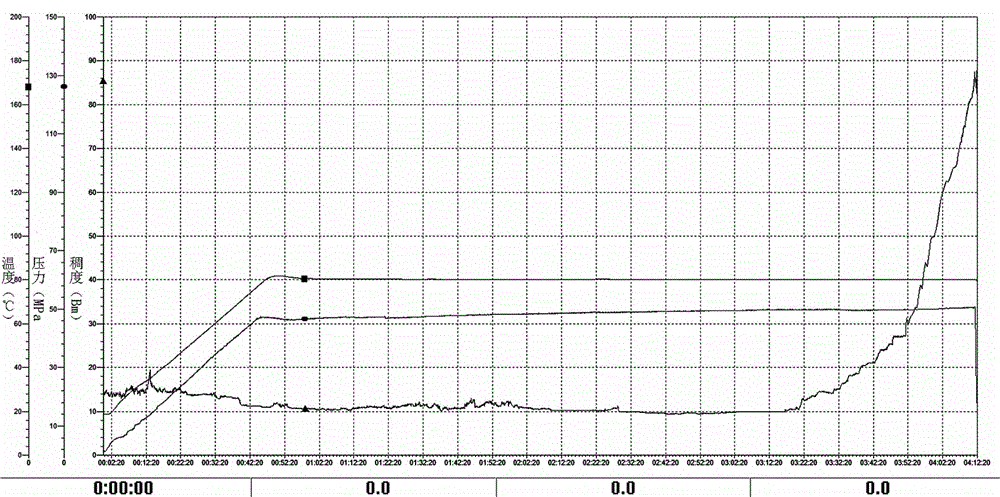

Embodiment 3

[0041] [Example 3] Anion-nonionic composite high-efficiency flushing solution, which is prepared from the following raw materials in mass percentage:

[0042]

[0043] The anion-nonionic composite high-efficiency flushing fluid also includes 1.0 g of a silicone ether copolymerized defoamer.

[0044] The preparation method of anion-nonionic composite high-efficiency flushing liquid, it comprises the following steps:

[0045] S1. Weigh the required mass percentage of raw materials, and heat the required water to 55°C;

[0046] S2. Add sodium tripolyphosphate and stir at 1200rpm for 30 minutes to fully dissolve it;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com