Electrified water washing robot of wheel type substation

A technology for substations and charged water, applied in manipulators, claw arms, manufacturing tools, etc., can solve the problems of high labor intensity, insufficient cleaning, equipment flashover, etc., to reduce labor intensity, improve washing efficiency and automation level, guarantee safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with accompanying drawing:

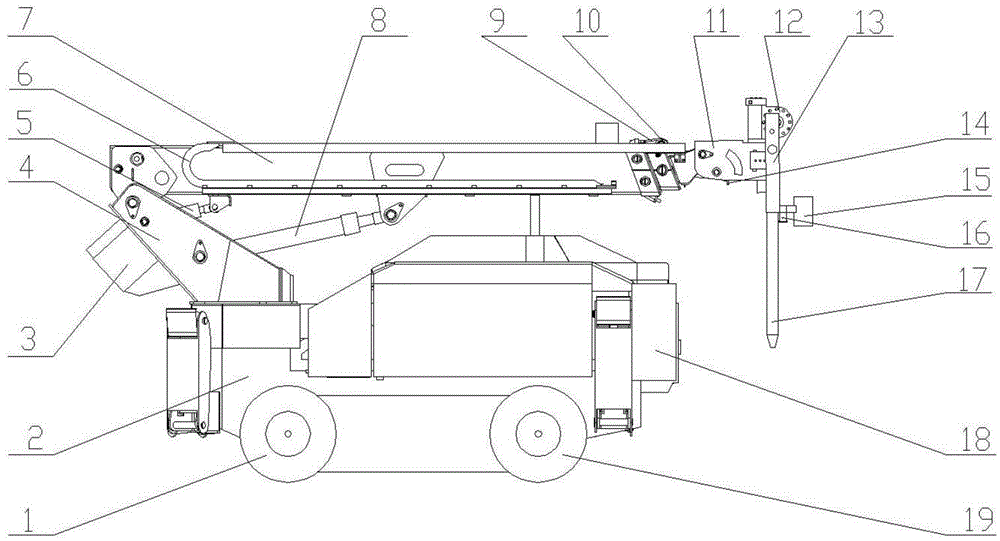

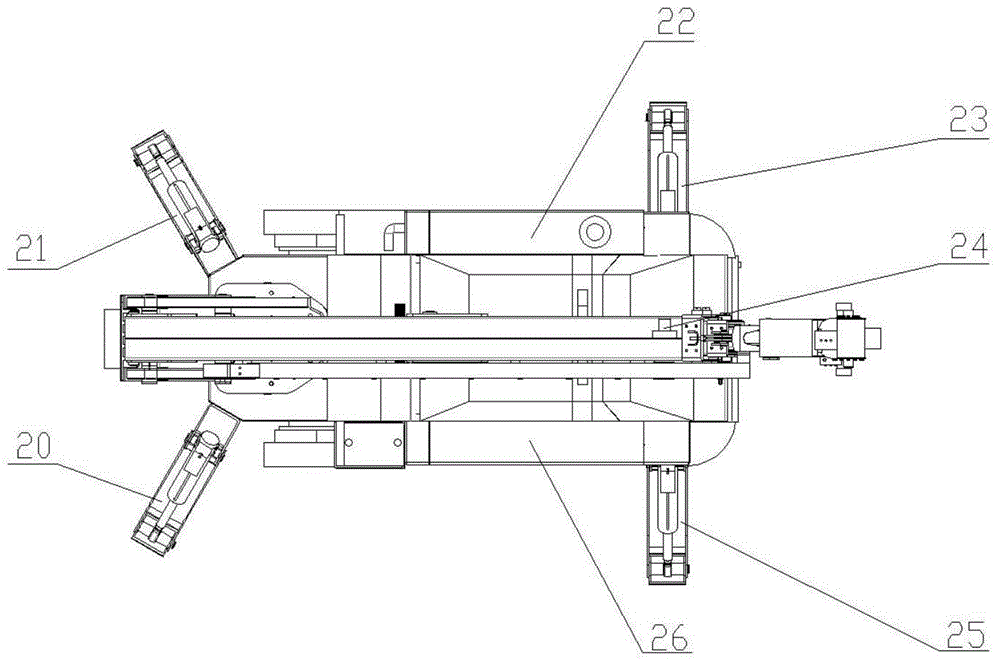

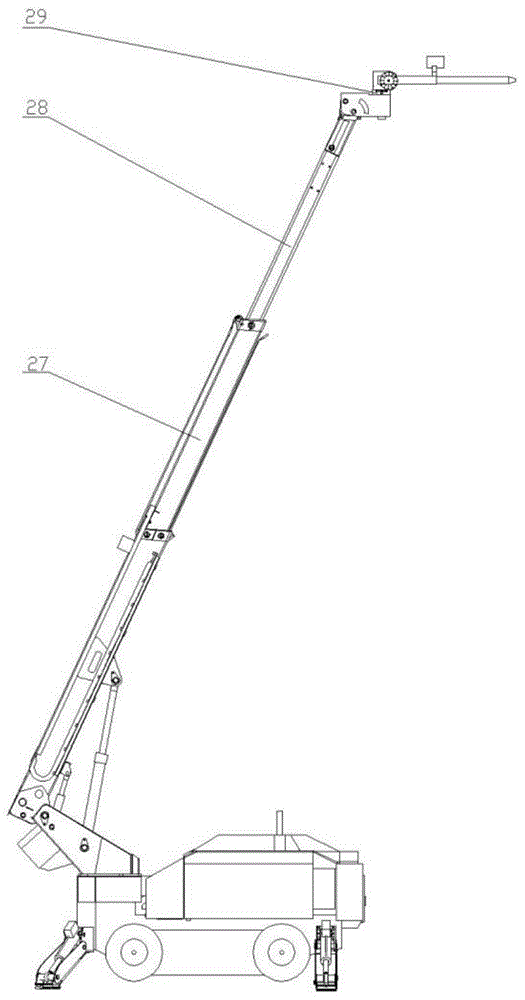

[0043] Such as Figure 1-3 As shown, a wheeled substation live water washing robot, the main body is composed of a mechanical body and a remote control device. Among them, the mechanical body is mainly composed of a car body moving mechanism, a three-section two-stage telescopic arm, a lifting mechanism, a water gun flushing mechanism, a hydraulic control system and an electrical control system. The vehicle body moving mechanism is a wheeled mobile chassis structure, one side of the wheeled chassis 2 is a diesel tank 26, and the other side is a hydraulic oil tank 22, and the power source of the robot is a vehicle-mounted diesel engine; The slewing platform 4 is connected, and the slewing platform 4 of the lifting mechanism is also equipped with a three-section two-stage telescopic arm. The small arm 28 of the three-section two-stage telescopic arm is connected with the workbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com