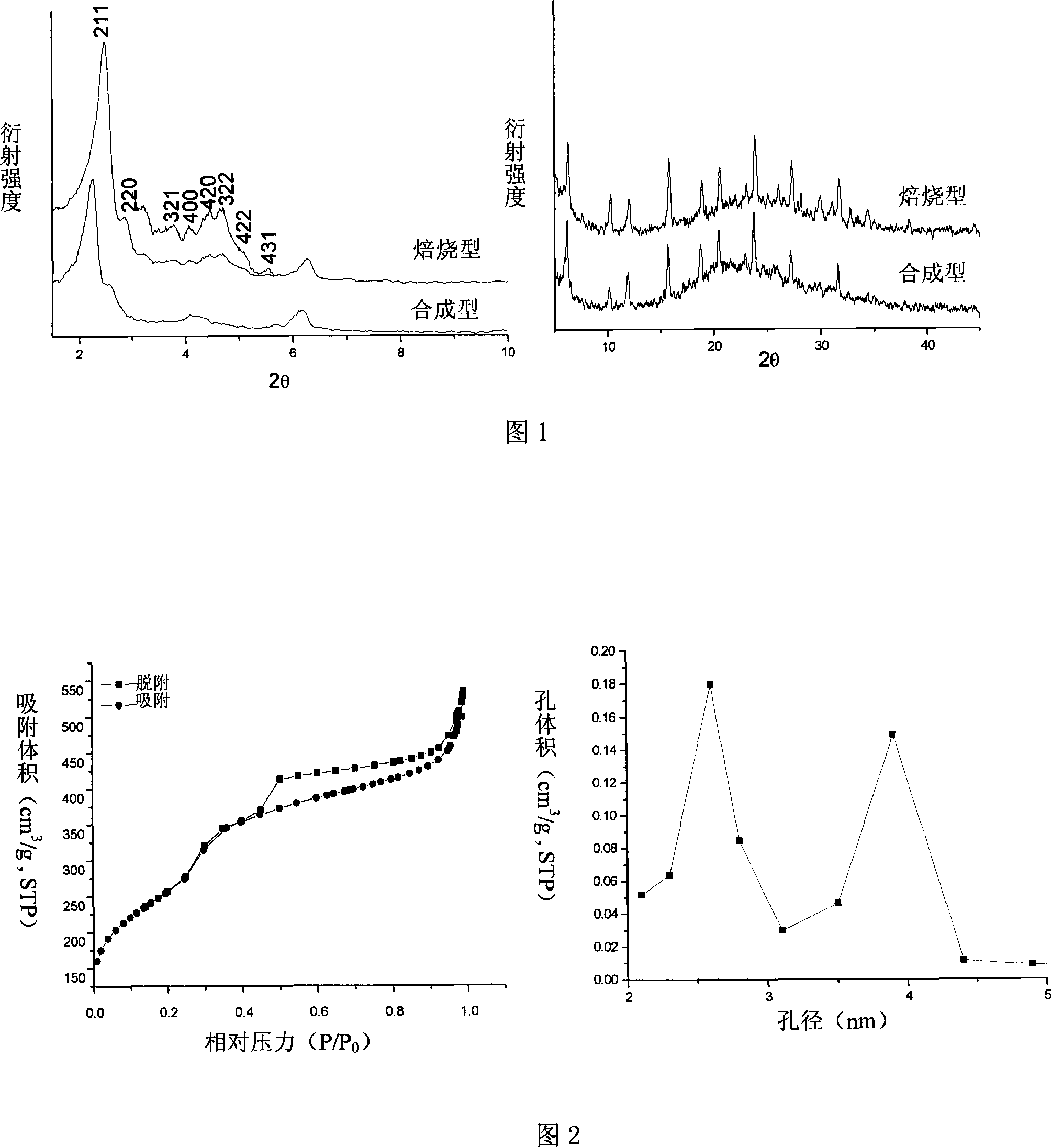

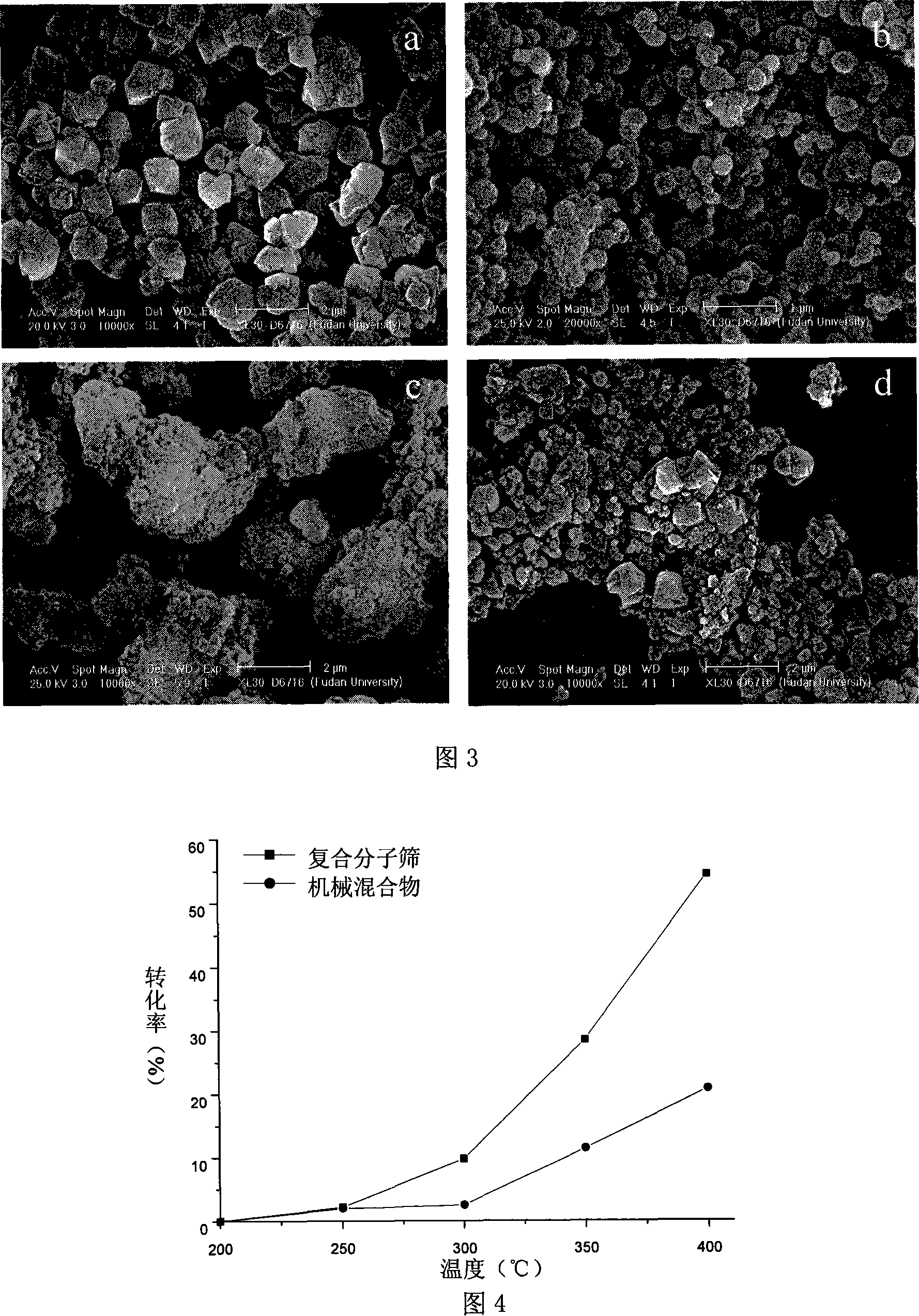

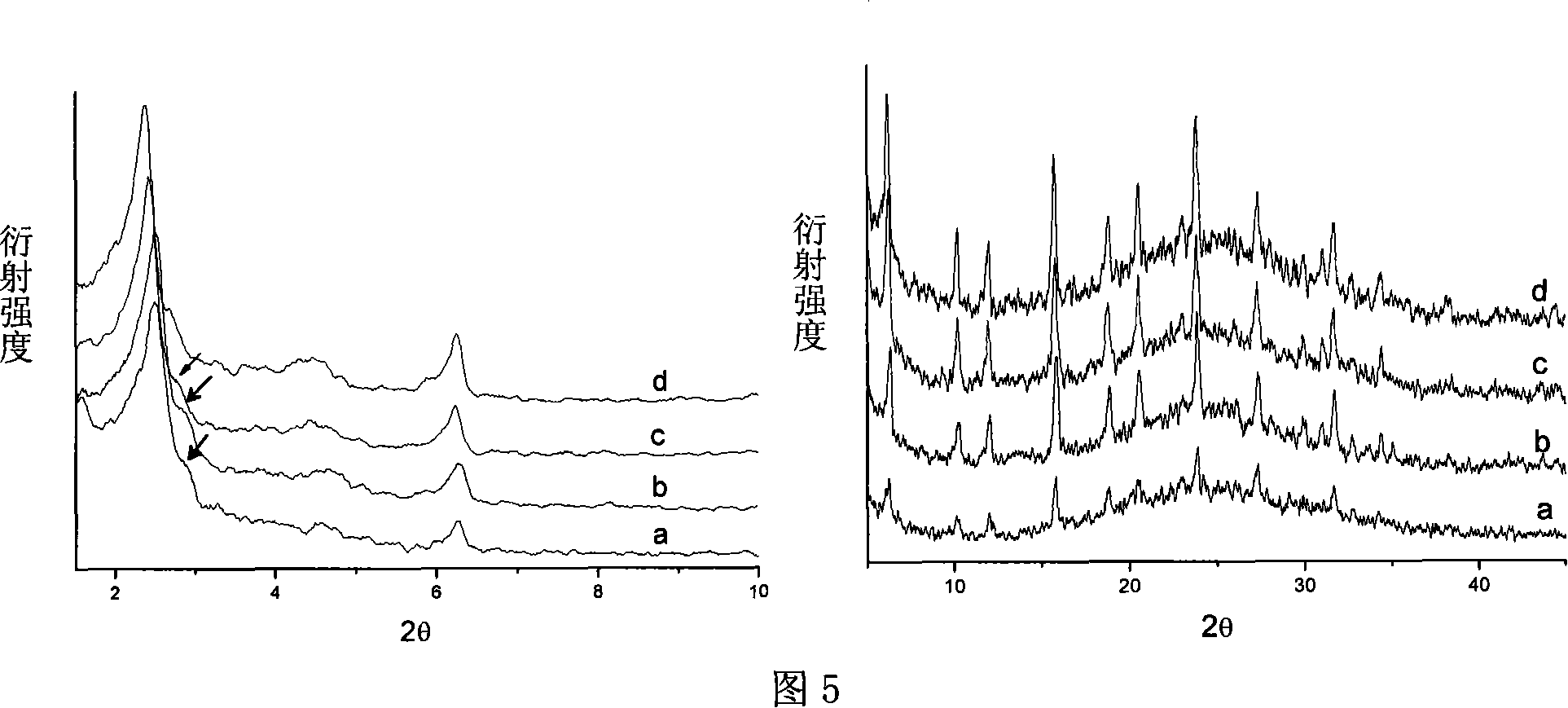

Y/MCM-48 composite molecular screen and preparation method thereof

A composite molecular sieve, MCM-48 technology, applied in the direction of molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of narrow formation phase area, uneconomical, harsh formation conditions, etc., and achieve the goal of reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Add 0.88g of finely ground Y zeolite powder to the mixed solution of CTAB and θP-10, stir quickly for 30min, and then add 5.7ml water glass (25.4wt% SiO 2 , 7.47wt%NaO 2 , 67.29wt%H 2O), stir at 30℃ for 2h to obtain a uniformly mixed starting gel with a molar composition ratio of 1 SiO 2 :0.15 CTAB: 0.025 OP-10: 0.28Na 2 O: 59 H 2 O, Y zeolite / SiO 2 (Mass ratio)=0.44. Adjust the PH≈10.6, put the sol into a 40ml reactor, crystallize at 100°C for 72h, and finally the product is filtered, washed, and dried to obtain Y / MCM-48 composite molecular sieve.

example 2

[0027] Add 1.76g of finely ground Y zeolite powder to the mixed solution of CTAB and OP-10, stir quickly for 30 minutes, and then add 5.7ml of water glass (25.4wt% SiO 2 , 7.47wt%NaO 2 , 67.29wt%H 2 O), stir at 40℃ for 1h to obtain a uniformly mixed starting gel with a molar composition ratio of 1 SiO 2 :0.15 CTAB: 0.025 OP-10: 0.28Na 2 O: 59 H 2 O, Y zeolite / SiO 2 (Mass ratio)=0.88. Adjust PH≈9, put the sol into a 40ml reactor, crystallize at 125°C for 12h, and finally the product is filtered, washed, and dried to obtain Y / MCM-48 composite molecular sieve.

example 3

[0029] Add 0.88g of finely ground Y zeolite powder to the mixed solution of CTAB and OP-10, stir quickly for 30 minutes, and then add 5.7ml of water glass (25.4wt% SiO 2 , 7.47wt%NaO 2 , 67.29wt%H 2 O), stir at 20℃ for 3h to obtain a uniformly mixed starting gel with a molar composition ratio of 1 SiO 2 : 0.17 CTAB: 0.020 OP-10: 0.20Na 2 O: 59 H 2 O, Y zeolite / SiO 2 (Mass ratio)=0.44. Adjust PH≈12, put the sol into a 40ml reaction kettle, crystallize at 75°C for 96h, and finally the product is filtered, washed, and dried to obtain Y / MCM-48 composite molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com