Synthesis of spherical Fe-MCM-48 mesoporous material and preparation of catalytic combustion catalyst loaded with Ag of spherical Fe-MCM-48 mesoporous material

A fe-mcm-48, mesoporous material technology, applied in physical/chemical process catalysts, catalyst carriers, molecular sieve catalysts, etc., can solve the problem of narrow utilization range and achieve the effect of good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

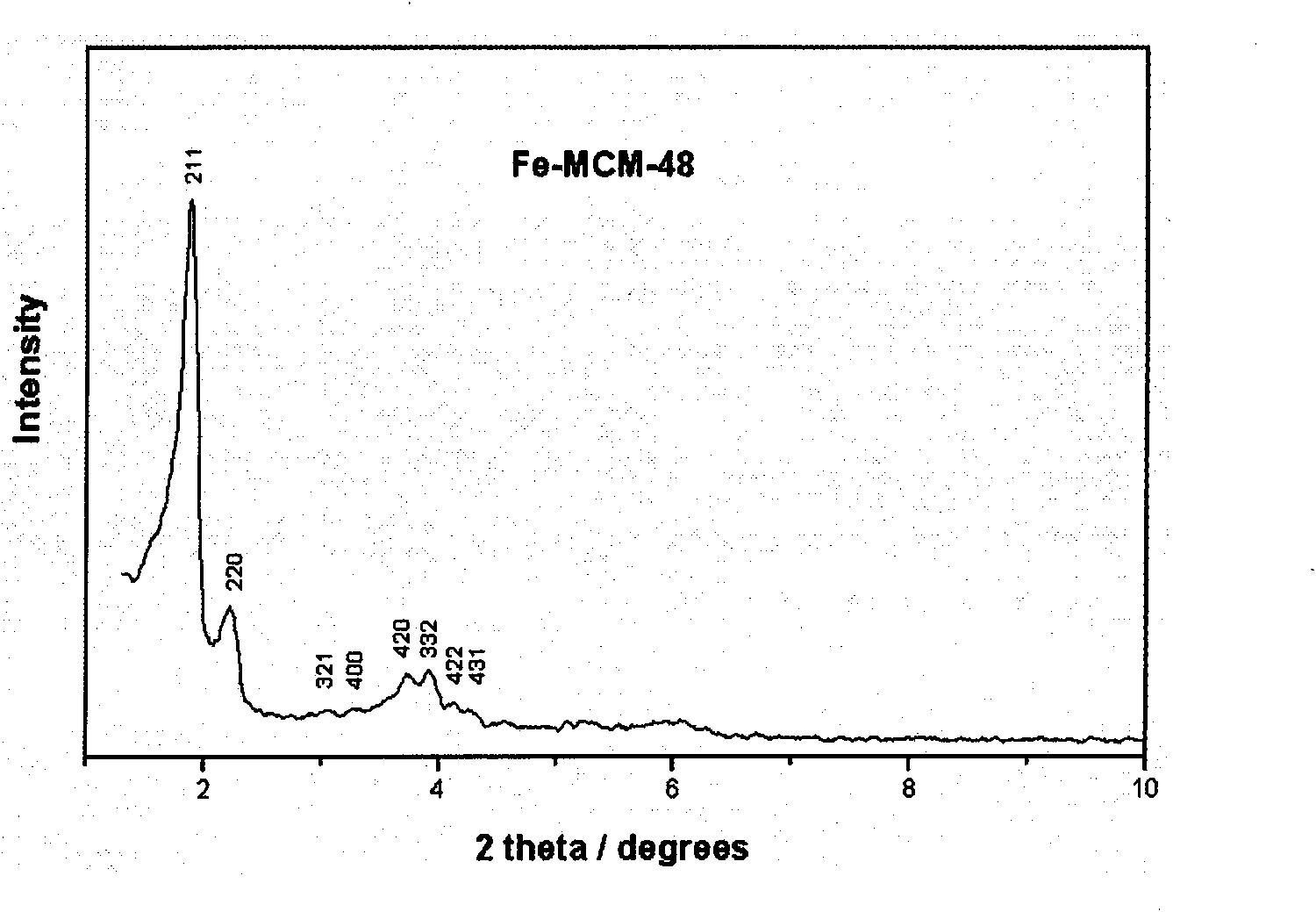

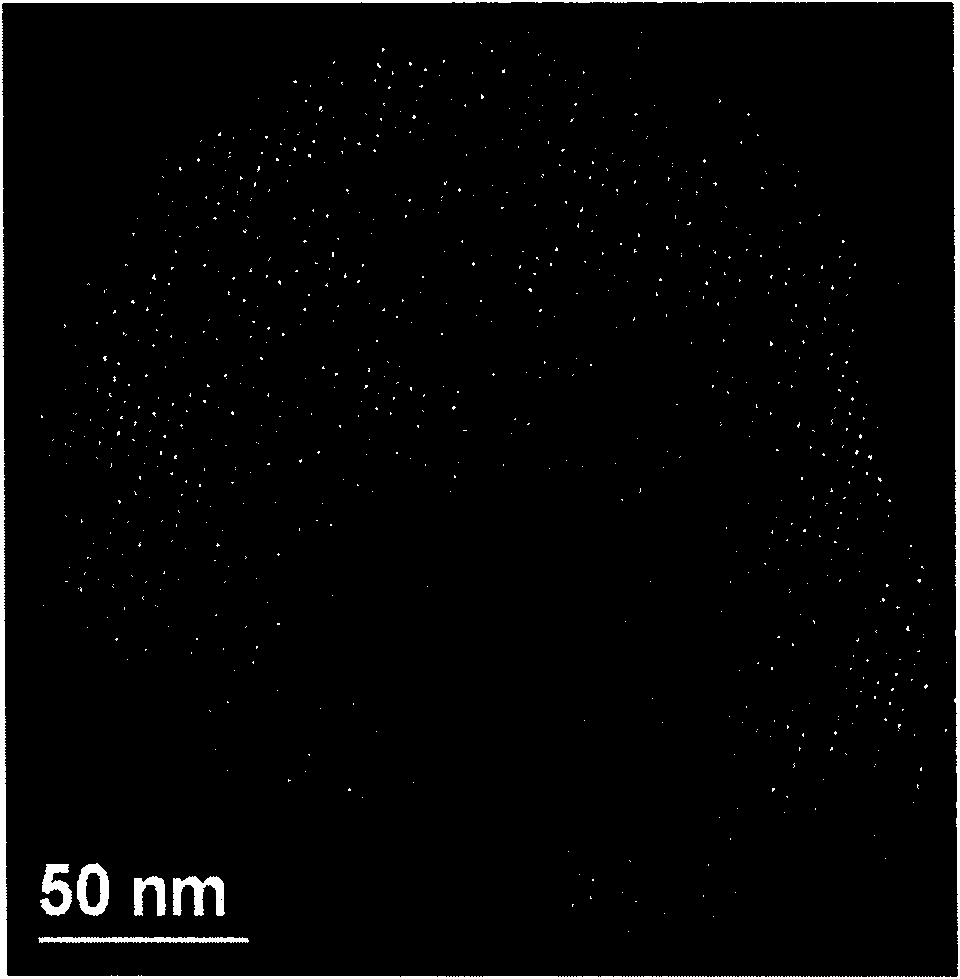

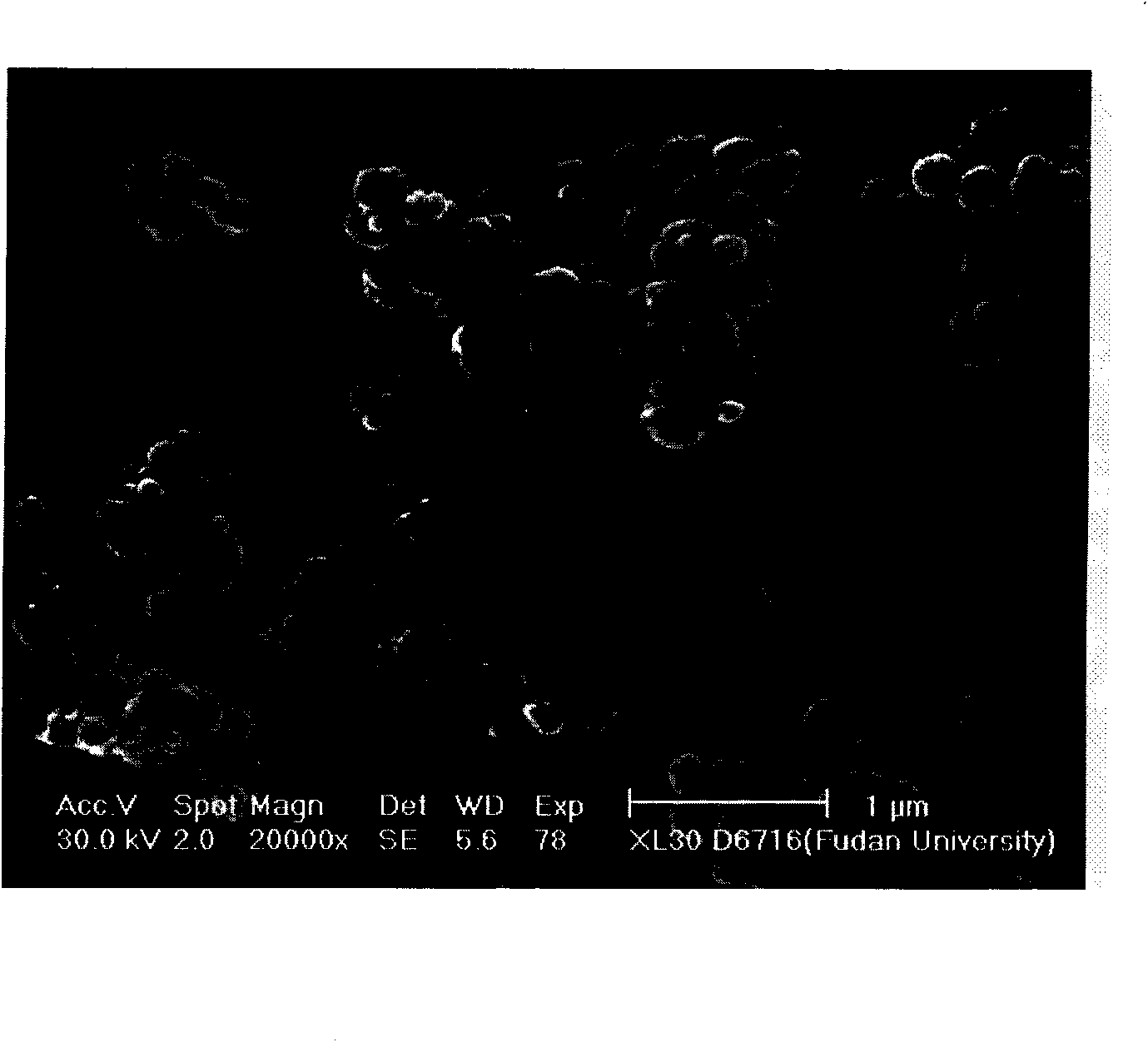

[0026] At room temperature, dissolve CTAB and Tx-100 in deionized water and stir to mix, then add water glass and ferric sulfate under stirring, continue to stir to form a homogeneous mixture, transfer this mixture into a reaction kettle, and crystallize in an oven at 100°C After 2 days, take it out, filter it with suction, wash it with deionized water, and dry it at 70°C to obtain a synthetic raw powder. After directly roasting the synthetic raw powder at 500°C for 4 hours in the air, you can get a spherical Fe-MCM-48 mesoporous molecular sieve sample . Typical XRD patterns, TEM photos, and SEM spectra are shown in Figure 1 ~ Figure 3 .

example 2

[0028] By equal volume impregnation method, 10% AgNO 3 Loaded on the spherical Fe-MCM-48 mesoporous molecular sieve, after standing overnight, calcined at 500°C for 3h, the spherical Fe-MCM-48 supported Ag catalytic combustion catalyst was obtained. The benzene catalytic combustion activity of this sample is shown in Table 1.

example 3

[0030] After the above-mentioned Ag / Fe-MCM-48 powder was pressed into tablets and sieved, 0.1 g of a 40-60 mesh sample was taken and placed in the center of a quartz tube fixed-bed reactor with an inner diameter of 6 mm for activity evaluation. Components were detected by FID. Air is the balance gas, the initial concentration of benzene is 1000PPM, and the space velocity is 100000h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com