Energy ray-curable resin composition and cured product thereof, and optical lens sheet

A technology of energy ray curing and resin composition, which is applied in the field of energy ray curing resin composition and its cured product and optical lens sheet, which can solve the problems of poor release performance, poor substrate adhesion and release performance, and high difficulty Refractive index and other issues, to achieve the effect of excellent adhesion, good light resistance, high refractive index

Inactive Publication Date: 2010-11-17

NIPPON KAYAKU CO LTD

View PDF7 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, cured products of these conventional energy ray-curable resin compositions have disadvantages such as poor adhesion to the substrate and poor releasability from the mold.

If the adhesion is poor, the types of substrates that can be used are limited, and it is difficult to obtain the required optical properties

If the releasability is poor, the resin will remain on the mold during demoulding, making the mold unusable

In addition, there is also a problem that the mold releasability of the energy ray-curable resin composition that provides a cured product with good adhesion is also good because the adhesion to the mold is also improved. On the other hand, the mold releasability is good Adhesion of energy ray curable resin composition tends to deteriorate

However, (meth)acrylates having a fluorene skeleton are neither disclosed nor suggested, and scratch resistance is insufficient.

In any case, it is difficult to simultaneously have a high refractive index, a high Tg point, mold release properties, adhesive properties, and low viscosity as an energy ray-curable composition used for an optical lens sheet with a high refractive index and a fine structure. , light resistance and scratch resistance, so a composition that satisfies all properties has not yet been obtained

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

Synthetic example 2

Synthetic example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Variable temperature | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Login to View More

Abstract

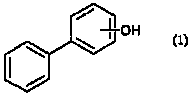

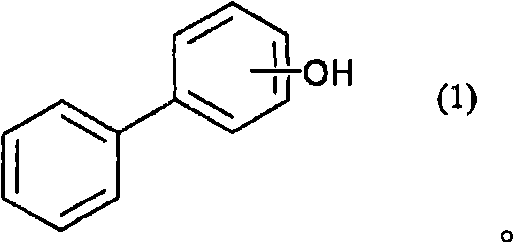

The invention provides an energy ray-curable resin composition having excellent demoulding character, mold reproducibility, bond strength with the substrate and light resistance; high refractivity; high glass-transition temperature and low viscosity. A energy ray-curable resin composition for optical lens sheets includes: a carbamate compound (A) obtained by reacting the epoxy resin (a), monocarboxylic acid compound (b) having ethylenically unsaturated group and aromatic polyisocyanic acid ester compound (c); a (meth) acrylate (B) having fluorene framework; a single acrylate monomer (C) with phenyl ether group; and a photopolymerization initiator (D), wherein the epoxy resin (a) is a reaction product of epihalohydrins and compound represented by the general formula (1).

Description

technical field The present invention relates to an energy ray curable resin composition, its cured product, and an optical lens sheet. More specifically, it relates to a resin composition and a cured product particularly suitable for lenses such as Fresnel lenses, lenticular lenses, prisms, and microlenses. Background technique At present, the above-mentioned lenses are formed by methods such as pressurization method and casting method (cast molding method). The former, that is, the pressurization method, is manufactured by circulating heating, pressurization, and cooling, so the productivity is poor. The latter, the casting method, has the problem of long production time because the monomer is injected into the mold for polymerization, and also has the problem of increased manufacturing cost because a plurality of molds are required. In order to solve the above-mentioned problems, various proposals have been made regarding the use of an energy ray-curable resin compositi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F283/00C08F283/10G02B1/04G02B3/00

CPCC08G18/58C08G18/72C08G18/76C08G59/063C08J5/18C08L33/06C08L75/04G02B1/04G02B3/08G02B5/30

Inventor 清柳典子市川淳子水口贵文内藤伸彦樱井弘设乐律子

Owner NIPPON KAYAKU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com